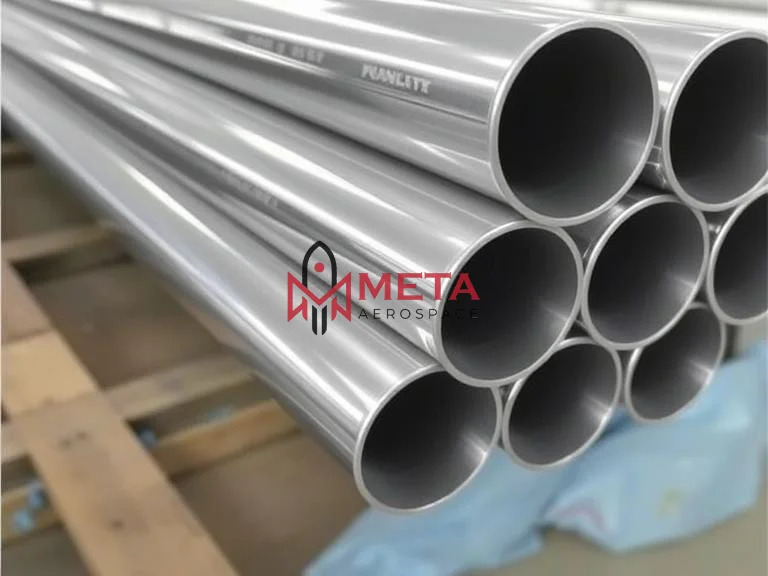

5754 Aluminium Pipes

MOQ : 50 Kilograms

5754 Aluminium Pipes Specification

- Surface Finish

- Mirror Polish

- Usage

- Industrial

- End Type

- Plain End, Beveled End, Threaded

- Material

- Aluminum

- Type

- Seamless

- Shape

- Round

- Surface Treatment

- Galvanized

- Color

- Sliver

- Warranty

- 1 Year

5754 Aluminium Pipes Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1 Kilograms Per Week

- Delivery Time

- 1-2 Week

About 5754 Aluminium Pipes

What Are Specification 5754 Aluminium Pipes?

| Aluminium 5754 Pipe Standards | ASTM B221, ASTM EN573, ASTM EN485 |

|---|---|

| Aluminium 5754 Round Pipe Size | OD 300MM, ID 100 MM , THICKNESS UPTO 50MM |

| Aluminium 5754 Square Pipe Size | OD 200MM , THICKNESS UPTO 10MM |

| Aluminium 5754 Rectangular Pipe Size | OD 200MM , ID 60MM , THICKNESS UPTO 15MM |

| Aluminium 5754 Pipe Length | 1000 mm to 8000 mm |

| Aluminium 5754 Pipe Tempers | O, H12, H14, H16, H18, H22, H24, H26, H112 |

| Aluminium 5754 Pipe Finish | As per Temper |

| Aluminium 5754 Pipe Delivery | 15 to 30 Working days From the Date of Purchase Order |

| Aluminium 5754 Pipe Origin | Indian, European, Germany, South Africa, Mexico, USA & Russian |

| Aluminium 5754 Pipe Test Certificate | EN 10204 3.1 Mill TC or Any 3rd party Inspection shall be Available. |

| Aluminium 5754 Pipe Packing & Shipping | Packing shall be SEA Worthy wooden packaging, with Fumigation as well as delivery of Aluminium 5754 Alloy Round Bars can be given by air & Sea as per clients requirements. |

| Aluminium 5754 Pipe Applications | Aircraft fuselage Commercial & military aircraft Wing tension members Critical Aircraft structures |

Chemical Composition Of 5754 Aluminium Pipes?

| Element | Content (%) |

|---|---|

| Aluminium / Aluminum, Al | 93.50 |

| Copper, Cu | 4.4 |

| Magnesium, Mg | 1.5 |

| Manganese, Mn | 0.6 |

Mechanical Properties Of 5754 Aluminium Pipes?

| Properties | Metric | Imperial |

|---|---|---|

| Elastic modulus | 70-80 GPa | 10152-11603 ksi |

| Poisson's ratio | 0.33 | 0.33 |

Versatile Industrial Applications

5754 Aluminium Pipes are engineered for diverse industrial uses due to their robust seamless construction and corrosion-resistant surface treatments. Their mirror-polished and galvanized finishes make them ideal for environments demanding both mechanical strength and visual appeal. The availability of different end types ensures easy integration into various systems, adding to their versatility.

Superior Quality & Reliable Sourcing

Manufactured and exported from India, these pipes are sourced from leading suppliers, manufacturers, and traders. Stringent quality control processes guarantee each pipe meets industry standards, ensuring clients receive superior, long-lasting products. The 1-year warranty further underscores the commitment to product reliability and customer satisfaction.

FAQs of 5754 Aluminium Pipes:

Q: How are 5754 Aluminium Pipes manufactured for industrial usage?

A: 5754 Aluminium Pipes are produced using a seamless process, which involves extruding premium aluminum to achieve a round, uniform shape without welds. This method ensures improved strength and leak resistance, making the pipes well-suited for industrial applications.Q: What are the benefits of a mirror-polished and galvanized surface finish on these pipes?

A: The mirror polish enhances the pipes aesthetic value while the galvanized treatment adds a protective layer against corrosion. These finishes ensure enhanced durability and visual appeal, especially in demanding industrial environments.Q: When should I choose plain end, beveled end, or threaded 5754 Aluminium Pipes?

A: The choice depends on your installation requirements. Plain end pipes are ideal for welding, beveled ends are suited for easy joining, and threaded ends facilitate screw connections. Selecting the right end type streamlines installation processes in industrial systems.Q: Where are these 5754 Aluminium Pipes typically used?

A: These pipes are widely used in industrial sectors such as chemical processing, construction, marine, and engineering due to their strength, corrosion resistance, and versatility. Their reliable performance makes them a preferred choice for demanding operational settings.Q: What is included in the 1-year warranty for 5754 Aluminium Pipes?

A: The 1-year warranty covers manufacturing defects and quality-related issues, ensuring customers receive pipes that function as intended in industrial operations. Warranty terms typically apply from the date of purchase, providing peace of mind.Q: How does the seamless type contribute to the pipes performance?

A: Seamless pipes are free of welds or joints, resulting in uniform strength along the entire length. This minimizes leakage risks and enhances pressure tolerance, which is particularly important for high-stress industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Aluminum Pipe Category

3003 Aluminium Pipes

Minimum Order Quantity : 50 Kilograms

Warranty : 1 Year

Alloy or Not : Is Alloy

Material : Aluminum

Type : Seamless

Usage : Industrial

5454 Aluminium Pipes

Minimum Order Quantity : 50 Kilograms

Warranty : 1 Year

Alloy or Not : NonAlloy

Material : Aluminum

Type : Seamless

Usage : Construction

6063 Aluminum Pipes

Minimum Order Quantity : 50 Kilograms

Warranty : 1 Year

Alloy or Not : NonAlloy

Material : Aluminum

Type : Seamless

Usage : Industrial

Aluminium 5083 Pipe

Minimum Order Quantity : 50 Kilograms

Warranty : 1 Year

Alloy or Not : Is Alloy

Material : Aluminum

Type : Seamless

Usage : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese