EN 10210 S355J2H Pipes

EN 10210 S355J2H Pipes Specification

- Coating Type

- Black Paint, Galvanized, Anti-rust Oil

- Thread Type

- N/A (mainly supplied without threads)

- Tolerance

- 1% or as per EN 10210-2

- Yield Strength

- 355 MPa

- Sealing Type

- Depends on end configuration

- Diameter

- 21.3 mm 508 mm

- Tensile Strength

- 510 MPa

- Flexibility

- Rigid

- Bend Radius

- Dependent on diameter and wall thickness

- Temperature Range

- -20C to 650C

- Connection Type

- Plain, Beveled, Threaded

- Product Type

- Seamless and Welded Steel Pipe

- Material

- Carbon Steel

- Connection

- Plain End, Beveled End

- Shape

- Round, Square, Rectangular

- Standard

- EN 10210-1, EN 10210-2

- Surface Treatment

- Black Painted, Bare, Oil Coated, Galvanized

- Outer Diameter

- 21.3 mm 508 mm

- Section Shape

- Hollow Section

- Length

- Single Random, Double Random, Custom Length up to 12 meters

- Thickness

- 2 mm 40 mm

- Color

- Black or as per requirement

- Usage

- Structural, Construction, Machinery, General Engineering

- Rated Pressure

- As per design/requirement

- Material Grade

- S355J2H

- Application

- Construction, Infrastructure, Bridges, Buildings, Machinery

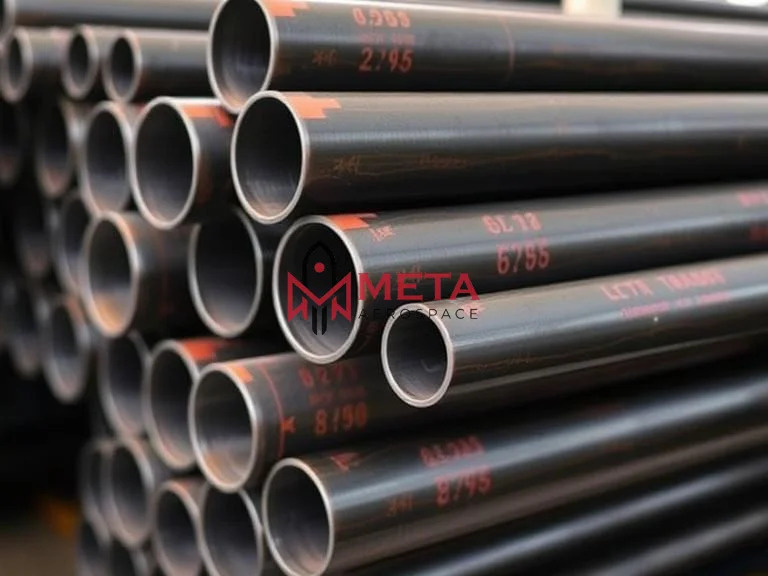

- Marking

- Standard marking as per EN 10210

- Packaging

- Bundles, Loose, or as per requirement

- Inspection

- Hydrostatic Testing, Ultrasonic Testing

- Weldability

- Excellent

- End Finish

- Plain End, Bevel End

- Cold Working

- Suitable for cold forming

- Elongation

- 22% min (L0 = 5.65S0)

- Impact Test

- 27J at -20C (Charpy V-Notch)

- Manufacturing Process

- Hot Finished or Cold Formed

- Non-Destructive Testing

- As per EN 10210 requirements

- Density

- 7.85 g/cm

About EN 10210 S355J2H Pipes

What Are Specification EN 10210 S355J2H Pipes?

| Standard | AISI, DIN, EN, GB, IS, JIS, ASTM, ASME Pipe |

|---|---|

| EN 10210 S355J2H Seamless Pipe Size | 4 to 219mm W. T.: 0.5 to 20mm |

| EN 10210 S355JOH Welded Pipe Size | 5.0 mm 1219.2 mm |

| Steel Grade S355JOH EFW Pipe size | 5.0 mm 1219.2 mm |

| Carbon Steel EN S355JOH Tube Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| S355JOH+N Pipe Schedule | SCH5, SCH10, SCH10S, SCH20, SCH30, SCH40, SCH40S, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| EN 10210 S355J2H Carbon Steel Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

| Carbon Steel EN S355JOH Welded Tube Size | 6.35 mm OD To 152 mm OD |

| Carbon Steel EN 10210 S355J2H Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| EN 10210-1 S355JOH Tube wall thickness | 0.020" 0.220", (special wall thicknesses available) |

| CS EN S355JOH Length | Single Random, Double Random, Standard & Cut length Pipe & Tube |

| S355JOH Carbon Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| Carbon Steel EN S355JOH Form | Round, Hydraulic, U bent or Hollow,LSAW, Boiler, Straight Pipe, Clad Pipe, Rectangular, Square Pipe Etc |

| EN 10210 S355JOH Type | Welded, Seamless, ERW, EFW, Fabricated Pipe, U bent or Hollow, Hydraulic, LSAW, Boiler, Straight Tube, Tube Coil, Round, Rectangular, Square Tube etc |

| Carbon EN 10210 S355J2H End | Plain End, Beveled End, Treaded Pipe & Tube |

| EN 10210 S355J2H Marking | All EN 10210 S355J2H Carbon Steel Seamless Pipes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customers request.) |

| Carbon EN 10210 S355J2H Steel Application | Oil Pipe & Tube, Gas Pipe & Tube, Fluid Pipe & Tube, Boiler Pipe & Tube, Heat exchanger Tube |

| Steel Grade S355JOH Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| EN 10210-1 Gr S355JOH Specialize in |

|

| Material Test Certificates (MTC) | Material Test Certificates (MTC) as per EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2, 100% Radiography Test Report, Raw Materials Certificate, Third Party Inspection Report, Fumigation Certificates, Heat Treatment Charts, Carbon Steel EN S355JOH Pipe HS Code Commercial Invoice, Form A for Generalized System of Preferences (GSP) |

| Manufacturers of Carbon EN 10210 S355J2H Steel Pipe |

|

| We can also cut, thread, and groove CS EN S355JOH Pipe to meet your specifications. Pipe Dimension ANSI/ ASME B36.19, B36.10, B2.1 | |

Equivalent material Of EN 10210 S355J2H Pipes?

| DIN | EN | BS | NFA | ASTM | ASME |

|---|---|---|---|---|---|

| EN 10210 S355J2H |

Chemical Composition Of EN 10210 S355J2H Pipes?

| Carbon | Silicon | Manganese | Phosphorous | Sulphur | Molybdenum | Nickel | Chromium | Copper | Others |

|---|---|---|---|---|---|---|---|---|---|

| max 0.22 | max 0.55 | max 1.60 | 0.04 | 0.04 | N0.009 |

Mechanical Properties Of EN 10210 S355J2H Pipes?

| Yield Strength | Tensile Strength | Elongation A5 min | |||

|---|---|---|---|---|---|

| MPa min | ksi min | MPa min | MPa min | ksi min | Percentage |

| 490 | 630 | 22 | |||

Versatile Manufacturing and Customizable Options

EN 10210 S355J2H pipes are produced using both hot finished and cold formed methods, allowing for precise dimensional control and flexibility. Customers can choose from a variety of end finishes, surface treatments, and packaging styles to meet specific project requirements. These pipes are available in round, square, and rectangular hollow sections, catering to diverse construction and engineering needs.

Exceptional Performance Under Challenging Conditions

Designed for durability, these pipes withstand pressures and temperatures from -20C up to 650C, while maintaining superior mechanical properties. With a high-impact resistance (Charpy V-notch 27J at -20C), excellent weldability, and the ability to undergo cold working, S355J2H pipes provide reliable performance in demanding structural and infrastructural settings.

FAQs of EN 10210 S355J2H Pipes:

Q: How are EN 10210 S355J2H pipes manufactured?

A: These pipes are produced using hot finished or cold formed manufacturing processes according to EN 10210-1 and EN 10210-2 standards. Hot finished pipes are formed at elevated temperatures, ensuring uniform mechanical properties, while cold formed pipes are shaped at room temperature for enhanced dimensional accuracy.Q: What impact and mechanical properties do these pipes offer?

A: EN 10210 S355J2H pipes provide a minimum impact energy of 27 Joules at -20C (Charpy V-notch). They exhibit a yield strength of at least 355 MPa, a tensile strength of 510 MPa or more, and a minimum elongation of 22%, making them suitable for applications demanding strength and toughness.Q: Where are EN 10210 S355J2H pipes commonly used?

A: These pipes are widely utilized in construction, infrastructure projects, bridges, buildings, general engineering, and machinery due to their structural integrity, dimensional versatility, and excellent weldability.Q: What is the inspection and testing process for these pipes?

A: Each pipe undergoes rigorous hydrostatic and ultrasonic testing to detect internal and surface flaws. Additionally, non-destructive tests are conducted as per EN 10210 requirements, ensuring compliance and safety.Q: How can the pipes be customized to suit specific project requirements?

A: Customers can specify the length (single, double random, or custom up to 12 meters), end finish (plain or beveled), surface treatment (black paint, galvanized, oil-coated), and packaging (bundles, loose, or tailored as per need) for their orders.Q: What are the benefits of using EN 10210 S355J2H pipes in construction and engineering?

A: These pipes combine high mechanical strength, excellent weldability, reliable impact resistance, and adaptability to various environmental conditions, resulting in long-term performance and safety for structural and engineering projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EN Standards Pipe Category

EN 10294-1 Grade E275K2 Pipes

Material : Carbon Steel

Surface Treatment : Other, Phosphated / Oiled / Bare

Standard : Other, EN 102941

Material Grade : E275K2

Usage : Machining, Structural Purposes, General Engineering

Connection : Other, Plain End / Beveled

EN 10210-1 Grade S355JOH Pipes

Material : Carbon Steel

Surface Treatment : Other, Black Painted, Galvanized, Bare

Standard : Other, EN 102101, EN 102191

Material Grade : S355JOH

Usage : Structural and Mechanical Applications

Connection : Other, Plain End, Beveled End, Threaded

EN 10025-5 S355J0W Pipes

Material : Other , Weathering steel

Surface Treatment : Other, Bare, Painted, Oil Coated, Anti Corrosive Coated

Standard : Other, EN 100255

Material Grade : S355J0W

Usage : Structural, Engineering, Outdoor Constructions, Bridges, Architectural

Connection : Other, Welded, Seamless, Threaded

EN 10219 S235JRH Pipes

Material : Carbon Steel

Surface Treatment : Other, Black Painted, Galvanized, Bare

Standard : Other, EN 10219

Material Grade : S235JRH

Usage : Structural, Construction, Engineering

Connection : Other, Welded / Plain End

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese