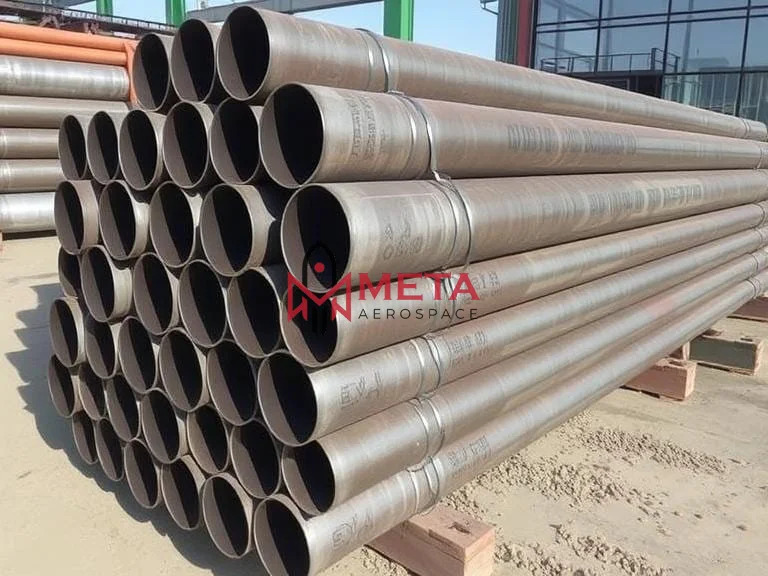

EN 10294-1 Grade E355+AR Pipes

EN 10294-1 Grade E355+AR Pipes Specification

- Thread Type

- As per customer specification

- Temperature Range

- -20C to +600C (depending on application)

- Tolerance

- 1% or as per EN 10294-1 standard

- Tensile Strength

- 590 - 770 MPa

- Yield Strength

- 470 MPa min

- Sealing Type

- Depends on end connection

- Diameter

- 21.3 mm to 457.2 mm

- Bend Radius

- As per standard or application

- Connection Type

- Welded / Threaded / Plain

- Coating Type

- Black Painted / Oiled

- Flexibility

- Rigid

- Product Type

- Hollow Bars / Pipes

- Material

- Seamless Carbon Steel

- Connection

- Plain End / Beveled End

- Shape

- Round

- Standard

- EN 10294-1

- Surface Treatment

- Black Painted / Bare / Oiled

- Outer Diameter

- 21.3 mm to 457.2 mm

- Section Shape

- Cylindrical

- Length

- Up to 12 Meters or as required

- Thickness

- 2.0 mm to 80 mm

- Color

- Black

- Usage

- Mechanical Engineering, Machining, Hydraulic Cylinder Applications

- Rated Pressure

- As per standard or customer requirement

- Application

- Automotive, Construction, Industrial Machinery, General Engineering

- Material Grade

- E355+AR

- Packing

- Hexagonal bundles, wrapped with HDPE/woven sheets

- Manufactured By

- Leading European and Indian mills

- End Finish

- Square Cut / Beveled / Threaded

- Hardness

- 230 HBW

- Manufacturing Process

- Seamless Hot Finished

- Chemical Composition

- C, Si, Mn, P, S as per EN 10294-1 E355

- Delivery Condition

- +AR (As Rolled)

- Heat Treatment

- None (As Delivered +AR)

- Inspection

- Ultrasonic & Eddy Current (on request)

- Corrosion Resistance

- Moderate; oiling or coating recommended

- Test Certificates

- EN 10204 3.1 / 3.2 Available

About EN 10294-1 Grade E355+AR Pipes

What Are Specification EN 10294-1 Grade E355+AR Pipes?

| EN 10294-1 Grade E355+AR Carbon Steel Square bar size | 4 to 100mm |

|---|---|

| EN 10294-1 Grade E355+AR Carbon Steel Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Carbon Steel EN 10294-1 E355+AR Hex Bar size | 2-100mm A/F |

| Carbon Steel EN 10294-1 E355+AR Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| EN 10294-1 Grade E355+AR Carbon Steel Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Carbon Steel EN 10294-1 E355+AR Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| EN 10294-1 Grade E355+AR Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| EN 10294-1 Grade E355+AR Carbon Steel Section | 3.0 to 12.0mm thickness |

| Carbon Steel EN 10294-1 E355+AR Round bar size | Diameter: 3-~800mm |

| Carbon Steel EN 10294-1 Grade E355+AR Billet Size | 1/2" to 495mm Diameter |

| CS EN 10294-1 Grade E355+AR Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| EN 10294-1 Grade E355+AR Carbon Steel Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Carbon Steel EN 10294-1 E355+AR Technique | Carbon EN 10294-1 Grade E355+AR Steel Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Steel EN 10294-1 Grade E355+AR Condition | Hardened & tempered, annealed |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Form | Grade 38Mn6 Carbon Steel Round, Rod, T-Bar, Nickel Alloy Channel Bar, Precision Ground Bar, Nickel Alloy Flat Bar, Nickel Alloy Square Bar, Nickel Alloy Blocks, Nickel Alloy Round Rod, Nickel Alloy Rings, Nickel Alloy Hollow, Nickel Alloy Triangle, Rectangle, Hex (A/F), Nickel Alloy Threaded, Half Round Bar, Profiles, Nickel Alloy Billet, Nickel Alloy Ingot, I/H Bar, Forging etc. |

| Processing | Bar cutting to 650mm |

| Our CS EN 10294-1 Grade E355+AR Round bar conforms to NACE MR0175/ISO 15156 | |

Equivalent material Of EN 10294-1 Grade E355+AR Pipes?

| DIN | EN | BS | NFA | ASTM | ASME |

|---|---|---|---|---|---|

| EN 10294-1 Grade E355+AR |

Chemical Composition Of EN 10294-1 Grade E355+AR Pipes?

| Carbon | Silicon | Manganese | Phosphorous | Sulphur | Molybdenum | Nickel | Chromium | Copper | Others |

|---|---|---|---|---|---|---|---|---|---|

| max 0.22 | max 0.50 | max 1.50 | 0.045 | 0.05 | max 0.08 | max 0.40 | max 0.30 | max 0.30 | V max 0.10 |

Mechanical Properties Of EN 10294-1 Grade E355+AR Pipes?

| Yield Strength | Tensile Strength | Elongation A5 min | |||

|---|---|---|---|---|---|

| MPa min | ksi min | MPa min | MPa min | ksi min | Percentage |

| 490 | 18 | ||||

Superior Manufacturing Process

These pipes are produced using the seamless hot finished method, ensuring uniform strength and integrity across the entire length. Manufactured without welds, the process results in a material ideal for heavy-duty mechanical and hydraulic applications, meeting EN 10294-1 Grade E355+AR standards.

Versatile Applications

EN 10294-1 Grade E355+AR pipes are widely used in automotive, construction, industrial machinery, and general engineering. Their consistent mechanical properties and wide size range make them a preferred choice for components requiring precise dimensional tolerance and elevated tensile strength.

Stringent Quality Assurance

Products are supplied with EN 10204 3.1 / 3.2 test certificates, confirming chemical composition and mechanical properties. Optional ultrasonic and eddy current inspections enhance reliability, while packing in hexagonal bundles with HDPE or woven sheets ensures safe transportation and storage.

FAQs of EN 10294-1 Grade E355+AR Pipes:

Q: How are EN 10294-1 Grade E355+AR pipes manufactured?

A: These pipes are produced using a seamless hot finished process, which involves forming the pipe without any welding, followed by as-rolled (+AR) delivery, ensuring consistent mechanical properties and optimal strength throughout.Q: What testing and certification is provided with these pipes?

A: Each batch comes with EN 10204 3.1 or 3.2 test certificates verifying chemical composition, tensile, and yield strength. Ultrasonic and eddy current inspections are available upon request to guarantee internal soundness and quality.Q: When should these pipes be coated or oiled?

A: As EN 10294-1 Grade E355+AR pipes offer moderate corrosion resistance, oiling or coating is recommended, especially for storage, transportation, or installation in corrosive environments, to enhance protection and service life.Q: Where can these pipes be applied?

A: They are utilized in automotive manufacturing, construction projects, hydraulic cylinder fabrication, industrial machinery, and general engineering, benefiting from their high strength, rigidity, and precise tolerances.Q: What are the available end finishes and connection types?

A: The pipes can be supplied with square cut, beveled, or threaded ends. Connections may be welded, threaded, or plain as per application needs, with thread types made according to customer specifications.Q: How does the seamless process benefit pipe performance?

A: Seamless pipes produced through the hot finished process offer superior uniformity, high tensile and yield strength (590-770 MPa, 470 MPa min), and reduced risk of defects, particularly important for hydraulic, mechanical, and high-pressure applications.Q: What is the temperature range for using these pipes?

A: EN 10294-1 Grade E355+AR pipes can be used in temperatures ranging from -20C to +600C, depending on the specific application and operational requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EN Standards Pipe Category

EN 10294-1 Grade E275K2 Pipes

Connection : Other, Plain End / Beveled

Surface Treatment : Other, Phosphated / Oiled / Bare

Standard : Other, EN 102941

Usage : Machining, Structural Purposes, General Engineering

Material Grade : E275K2

Material : Carbon Steel

EN 10025 S355j2 Pipes

Connection : Other, Welded/Seamless

Surface Treatment : Other, Black Painted, Bare, Galvanized, Anticorrosion Oil Coated

Standard : Other, EN 10025

Usage : Construction, Engineering, Structural Applications

Material Grade : S355J2

Material : Other , S355J2 Carbon Steel

EN 10210-1 Grade S355JOH Pipes

Connection : Other, Plain End, Beveled End, Threaded

Surface Treatment : Other, Black Painted, Galvanized, Bare

Standard : Other, EN 102101, EN 102191

Usage : Structural and Mechanical Applications

Material Grade : S355JOH

Material : Carbon Steel

EN 10216-1 P235TR2 Pipes

Connection : Other, Plain End, Beveled End

Surface Treatment : Other, Black Painted, Oiled or Bare

Standard : Other, EN 102161

Usage : Fluid Transmission, Boiler, Mechanical, Gas, Oil

Material Grade : P235TR2

Material : Carbon Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese