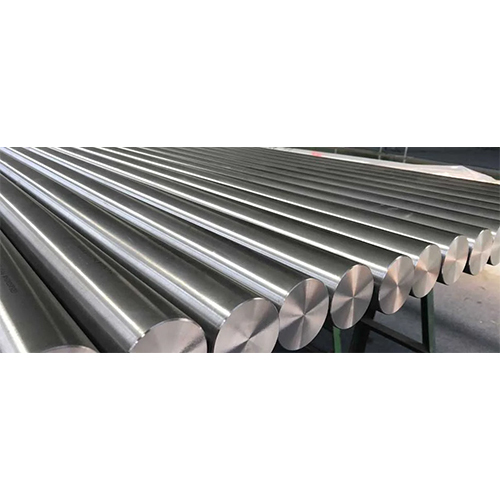

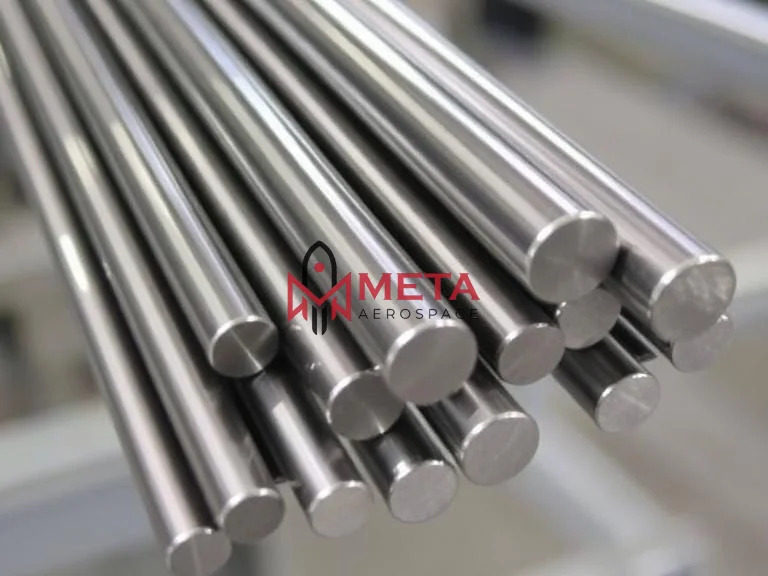

Hastelloy C2000 Round Bars

Hastelloy C2000 Round Bars Specification

- Tolerance

- H9, H11, K9 or as per requirement

- Type

- Round Bar

- Grade

- C2000

- Specific Use

- Corrosion Resistant Applications

- Material

- Hastelloy C2000

- Length

- 2-6 meters, Custom Cut Lengths Available

- Processing

- Peeled, Ground, Centerless Polished

- Diameter

- 10 mm to 200 mm

- Technique

- Hot Rolled / Cold Drawn

- Standard

- ASTM B574, ASME SB574

- Application

- Chemical Processing, Petrochemical, Power Generation

- Finish

- Bright, Black, Polished

- Packaging

- Standard Export Packaging (Wooden Cases/Bundles)

- Form

- Straight Bar or Bar Bundle

- Yield Strength

- 283 MPa (min)

- Melting Point

- 1325 1370 C

- Edge Condition

- Sharp Edges / Rounded Edges

- Tensile Strength

- 690 MPa (min)

- Elongation

- 20% (min)

- Hardness

- Rockwell B90 max

- Density

- 8.50 g/cm

About Hastelloy C2000 Round Bars

What Are Specification Hastelloy C2000 Round Bars?

| Specifications | ASTM B 574 / ASME SB 574 |

|---|---|

| Range | 3.17mm to 350mm diameter |

| Dia Meter | 25mm to 152mm |

| Length | 1 to 6 Meters, Custom Cut Lengths |

| Finish | Bright, Polish & Black |

| Form | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging etc |

| Condition | Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished |

Equivalent material Of Hastelloy C2000 Round Bars?

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Hastelloy C2000 | 2.4675 | N06200 |

Chemical Composition Of Hastelloy C2000 Round Bars?

| UNS | Ni | Cr | Mo | W | Cu | Fe | Carbon |

|---|---|---|---|---|---|---|---|

| C2000 | Bal | 22.00-24.00 | 15.00-17.00 | 1.30-1.90 | 3.00 max. | 0.010max. |

Mechanical Properties Of Hastelloy C2000 Round Bars?

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Hastelloy C2000 | 8.89 g/cm3 | 1065 C (1950 F) | 752 MPa (109.0 ksi) | 358 MPa (52.0 ksi) | 64 % |

Superior Corrosion Resistance

Hastelloy C2000 Round Bars are engineered to withstand highly corrosive environments, including those with oxidizing and reducing agents. Their unique composition ensures durability in aggressive chemical and petrochemical applications, minimizing maintenance and replacement needs.

Precision Manufacturing and Customization

Available in hot rolled or cold drawn forms, these bars are processed through peeling, grinding, and centerless polishing to achieve bright, black, or polished finishes. Customers can select from various tolerances and edge conditions, with lengths from 2 to 6 meters or customized to specific project requirements.

Reliable Quality and Certification

Each bar adheres to strict international standards such as ASTM B574 and ASME SB574. Manufactured by trusted exporters, manufacturers, and suppliers in India, these round bars come with documentation and inspection reports, ensuring reliability for end users in critical industries.

FAQs of Hastelloy C2000 Round Bars:

Q: How are Hastelloy C2000 Round Bars typically processed and finished?

A: Hastelloy C2000 Round Bars can be hot rolled or cold drawn, then further processed through peeling, grinding, or centerless polishing. They are available in finishes such as bright, black, or polished, depending on customer requirements.Q: What applications are ideal for Hastelloy C2000 Round Bars?

A: These round bars are best suited for industries requiring exceptional corrosion resistance, including chemical processing, petrochemical, and power generation, where harsh media and high strength are essential.Q: When should I choose Hastelloy C2000 Round Bars over other alloys?

A: Select Hastelloy C2000 Round Bars when your application demands both resistance to a broad spectrum of corrosive environments and high mechanical properties, particularly in aggressive chemical or marine settings.Q: Where are these round bars manufactured and supplied from?

A: Our Hastelloy C2000 Round Bars are manufactured and exported by reputed companies in India, serving both domestic and international markets with standard export packaging such as wooden cases or bundles.Q: What is the typical process for ordering custom cut lengths?

A: To order custom cut lengths, you provide the required specificationslength, diameter, tolerance, and edge condition. The manufacturer or supplier will process the bars according to your requirements and deliver them with proper certification.Q: How does the material grade C2000 benefit corrosion-resistant applications?

A: Grade C2000 offers exceptional resistance against both oxidizing and reducing chemicals, reducing maintenance costs and downtime, and ensuring longer service life in environments where standard alloys may fail.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hastelloy Bar Category

Hastelloy B3 Round Bars

Finish : Polished, Bright, Black

Technique : Hot Rolled, Cold Drawn

Material : Hastelloy B3

Grade : B3

Application : Chemical Processing, Petrochemical, Pharmaceutical, Power Generation

Standard : ASTM B335

Hastelloy C276 Round Bars

Finish : Bright, Polished, Black, Peeled or Turned

Technique : Hot Rolled / Cold Drawn

Material : Hastelloy C276

Grade : C276 (UNS N10276)

Application : Chemical Processing, Pollution Control, Pulp and Paper Production, Waste Treatment, Industrial Applications

Standard : ASTM B574, ASME SB574

Hastelloy C22 Bar

Finish : Polished

Technique : Hot Rolled

Material : Stainless Steel

Grade : Multiple Grades Available

Maraging 250 Round Bars

Finish : Bright, Polished

Technique : Hot Rolled / Cold Drawn

Material : Maraging Steel 250

Grade : Maraging 250

Application : Aerospace, Defense, Tooling, HighPerformance Engineering

Standard : ASTM A579 / A579M, AMS 6512, DIN 1.6359

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese