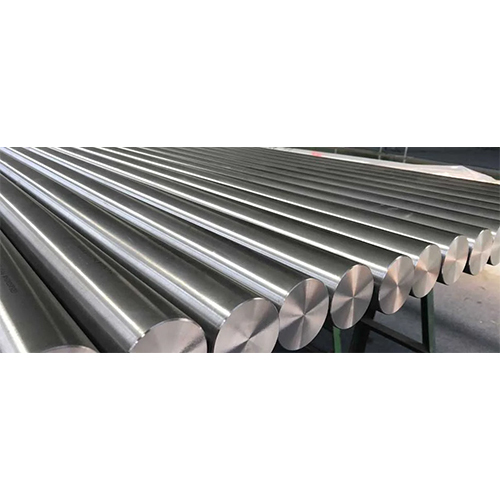

Maraging 300 Round Bars

Maraging 300 Round Bars Specification

- Length

- 100 mm to 6000 mm

- Material

- Maraging Steel 300

- Grade

- Maraging 300

- Specific Use

- High-Strength Critical Components

- Processing

- Precision Ground, Peeled, Centerless Ground

- Tolerance

- H9, H10, H11, 0.05 mm

- Technique

- Cold Drawn / Hot Rolled

- Type

- Round Bar

- Standard

- ASTM A579 / A920, AMS 6514

- Finish

- Bright, Black, Polished

- Application

- Aerospace, Tooling, Defense, Engineering Components

- Diameter

- 2 mm to 350 mm

- Magnetism

- Magnetic

- Hardness

- Rockwell C 50-55 (after aging)

- Surface Condition

- Smooth and Defect-Free

- Density

- 8.1 g/cm

- Corrosion Resistance

- Good

- Microstructure

- Martensitic

- Ultimate Tensile Strength

- Up to 2,050 MPa

- Heat Treatment

- Solution Annealed & Aged

- Elongation

- 812% (after aging)

- Manufacturer Certification

- Available upon Request

- Yield Strength

- Up to 2,030 MPa

About Maraging 300 Round Bars

What Are Specification Maraging 300 Round Bars?

| Specifications | AMS 6512 |

|---|---|

| Dimension Standard | ASTM, ASME, AMS, GB/T, JIS |

| Bar Diameter | range from 0.125 to 14.00 diameter |

| Flat Bar Thickness | 0.1-600mm,etc |

| Flat Bar Size | 1-2500mm, etc |

| Length | 1-12m, Random, Fix & Cut Length or as per clients requirement |

| Bar Surface | Bright, Polish & Black |

| Form | Round, Flat, Polished & Bright Finish |

Equivalent material Of Maraging 300 Round Bars?

| STANDARD | UNS | Material No | AMS | ASTM | Mil-S | BS | DTD | MSRR |

|---|---|---|---|---|---|---|---|---|

| Maraging Steel | K92890, K93120, S35000 | 6512 | A538 | 46850D | S162 | 5212 | 6551 |

Chemical Composition Of Maraging 300 Round Bars?

| Grade | C | Mn | Si | Co | Fe | Ni | Mo | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Maraging 300 | .03max max | .10max max | .10max max | 7.50 max | Bal | 18.50 min | 4.80 max | .40 max | .10 max |

Mechanical Properties Of Maraging 300 Round Bars?

| Grade | Density | Average Coefficient of Thermal Expansion | Modulus of Elasticity |

|---|---|---|---|

| Maraging 300 | .289 lbs./cu.in | 5.6 x 10-6 in./ in./ F | 5.6 x 10-6 in./ in./ F |

Superior Mechanical Performance

Maraging 300 Round Bars provide remarkable strength and high toughness due to advanced heat treatment processes, meeting demanding requirements for aerospace and other cutting-edge industries. With yield and tensile strengths exceeding 2,000 MPa and reliable elongation after aging, these bars ensure both durability and controlled flexibility in applications where failure is not an option.

Precision Processing & Versatile Finishes

Utilizing cold drawn or hot rolled techniques, Maraging 300 bars are available in bright, black, polished, precision ground, peeled, or centerless ground surfaces. They offer precise tolerances (H9, H10, H11, 0.05 mm), making them ideal where accuracy and a flawless finish are critical for high-performance assemblies. Smooth, defect-free surfaces enhance both aesthetics and functionality.

Certified Quality for Critical Applications

Manufactured according to international standards (ASTM A579/A920, AMS 6514), Maraging 300 bars from India are supplied with manufacturer certifications upon request. This quality assurance and compliance enable their use in critical sectors such as aerospace, defense, engineering, and high-strength tooling, ensuring dependable performance under extreme operational conditions.

FAQs of Maraging 300 Round Bars:

Q: How are Maraging 300 Round Bars processed to achieve high mechanical strength?

A: Maraging 300 Round Bars undergo a solution annealing process, followed by precise aging. This heat treatment refines the martensitic microstructure, leading to a Rockwell C hardness of 50-55 and enabling extremely high yield and tensile strengths, up to 2,030 MPa and 2,050 MPa respectively.Q: What types of finishes and tolerances are available for Maraging 300 Round Bars?

A: These round bars can be supplied in bright, black, and polished finishes, with options like precision ground, centerless ground, or peeled surfaces. Tolerances offered include H9, H10, H11, and fine accuracy up to 0.05 mm, suitable for applications demanding tight dimensional control.Q: When should Maraging 300 Round Bars be selected over conventional steel bars?

A: Maraging 300 Round Bars are ideal for applications where extreme strength, ductility, and toughness are essentialsuch as aerospace components, high-strength tooling, and defense partsoutperforming conventional steels in demanding settings requiring exceptional reliability.Q: Where can Maraging 300 Round Bars be sourced from in India?

A: These bars are manufactured, supplied, exported, and traded by leading metallurgical firms in India, with the option to request certifications confirming adherence to ASTM and AMS standards.Q: What is the benefit of the martensitic microstructure in Maraging 300 Round Bars?

A: The martensitic microstructure, achieved through meticulous heat treatment, imparts superior strength, consistent magnetism, and good corrosion resistance, ensuring performance reliability in critical engineering applications.Q: How does the surface condition affect the usage of Maraging 300 Round Bars?

A: A smooth and defect-free surface, obtained through advanced processing like precision grinding and peeling, minimizes stress concentrations, enhances fatigue life, and ensures the material meets the stringent visual and technical standards required for high-precision environments.Q: What certification and standards are available for Maraging 300 Round Bars?

A: Manufacturer certifications confirming compliance with ASTM A579/A920 and AMS 6514 standards are available upon request, ensuring product authenticity and suitability for regulated industries such as aerospace and defense.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hastelloy Bar Category

Hastelloy C22 Bar

Minimum Order Quantity : 50 Kilograms

Finish : Polished

Technique : Hot Rolled

Grade : Multiple Grades Available

Material : Stainless Steel

Hastelloy Round Bar

Minimum Order Quantity : 50 Kilograms

Finish : Polished

Technique : Hot Rolled

Grade : Multiple Grades Available

Material : Stainless Steel

Hastelloy C276 Round Bars

Finish : Bright, Polished, Black, Peeled or Turned

Technique : Hot Rolled / Cold Drawn

Grade : C276 (UNS N10276)

Material : Hastelloy C276

Application : Chemical Processing, Pollution Control, Pulp and Paper Production, Waste Treatment, Industrial Applications

Hastelloy X Round Bars

Finish : Bright, Polished, Black

Technique : Cold Rolled, Hot Rolled

Grade : Hastelloy X (UNS N06002)

Material : Hastelloy X

Application : Aerospace, Petrochemical, Gas Turbine components, Industrial heating

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese