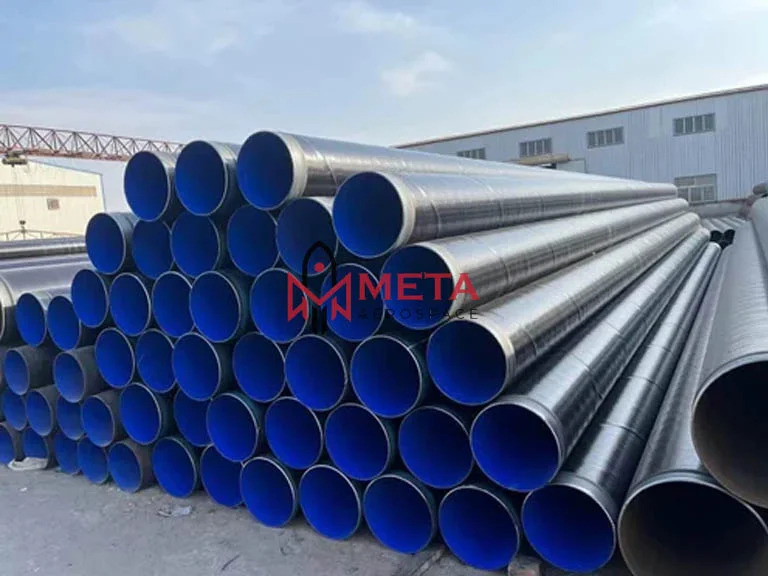

S275JR Pipes

MOQ : 50 Kilograms

S275JR Pipes Specification

- Usage

- Industrial

- Material Grade

- Q195

- Material

- Steel

- Section Shape

- Round

- Standard

- ASTM

- Technique

- Hot Rolled

- Surface Treatment

- Galvanized

S275JR Pipes Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1 Kilograms Per Week

- Delivery Time

- 1-2 Week

About S275JR Pipes

What Are Specification S275JR Pipes?

| Specification |

|

|---|---|

| Standard |

|

| Material |

|

| Pipe Size | 1/2 38 (DN15-950) |

| Wall Thickness | SCH10, SCH20, SCH30, STD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160, XXS |

| Length | Fixed: 5.8m, 5.85m, 5.9m, 6.0m, 11.8m, 12m.Random length: 4-12m |

| Application |

|

| Surface | Hot / cold galvanized, Black painting,varnish paint, anti rust oil, Coal Tar Epoxy, Bitumen Coating, 3PE, Fusion bond Epoxy coating, |

| Packing | Plastic caps on both ends,Steel bundle,Woven bag or as per request |

| Specialized in | Electric Resistance Welded Steel Pipe |

| Mfg. Process |

|

| Mill Test Certificate (MTC) | EN 10204/3.1B |

Chemical Composition Of S275JR Pipes?

| Grade | C max | Mn1 max | P max | S max | Si | Nb, Ti |

|---|---|---|---|---|---|---|

| 1008 (Si 0,03%) | 0,10 | 0,50 | 0,025 | 0,025 | 0,005-0,035 | |

| S275 Tube | 0,20 | 1,50 | 0,040 | 0,040 | 0,035 max | |

| S355 Tube | 0,14 | 1,50 | 0,035 | 0,030 | 0,15-0,25 | 0,050 each |

| S275 Pipe | 0,21 | 1,50 | 0,035 | 0,010 |

Mechanical Properties Of S275JR Pipes?

| Grade | Yield strength (MPa) | Tensile strength (MPa) | Minimum elongation A5 (%) | Impact Test 2 (J) |

|---|---|---|---|---|

| 1008 (Si 0,03%) | None | None | None | None |

| S275 Tube | 275-375 | 430/4151-530 | 20 | 27 @ 0C |

| S355 Tube | 355-475 | 450-550 | 22 | 27 @ 0C |

| S275 Pipe | Min. 275 | 410-560 | 23 | 27 @ 20 C (Optional) |

Unmatched Quality for Industrial Applications

Our S275JR steel pipes are engineered for resilience and versatility, making them ideal for heavy-duty industrial requirements. Galvanized and hot rolled, these pipes offer enhanced strength and corrosion protection. They are suitable for construction, infrastructure, mechanical, and general fabrication projects, delivering consistent performance where it matters most.

Efficient Manufacturing and Standards Compliance

Utilizing the hot rolling technique, our pipes are carefully fabricated from Q195 grade steel, ensuring uniformity and structural integrity. Each pipe adheres to ASTM standards, meeting global benchmarks for quality and safety. The galvanized surface treatment further extends the pipes operational life, making it a preferred choice among professionals.

FAQs of S275JR Pipes:

Q: How are S275JR pipes manufactured and what is their technique?

A: S275JR pipes are manufactured using the hot rolling process, which involves shaping Q195 grade steel at high temperatures. This method enhances material strength and uniformity, resulting in robust, round-section pipes suitable for industrial use.Q: What are the primary industrial applications of galvanized S275JR pipes?

A: These pipes are used in a range of industrial applications, including construction frameworks, infrastructure development, mechanical systems, and as components in general fabrication projects. Their strength and durability make them ideal for environments with high demands.Q: When should I choose a galvanized S275JR pipe over other types?

A: Galvanized S275JR pipes are best selected when long-term resistance to rust and environmental wear is essential, such as in outdoor structures, exposed pipelines, or corrosive industrial settings.Q: Where can S275JR pipes be sourced from in India?

A: We are a reputable exporter, manufacturer, supplier, and trader of S275JR pipes in India, providing quality products to both domestic and international markets with prompt delivery and reliable support.Q: What benefits does the ASTM standard provide for S275JR pipes?

A: Adhering to ASTM standards ensures that S275JR pipes consistently meet high benchmarks for performance, strength, and safety, offering customers peace of mind and dependable long-term use.Q: Which surface treatment is applied to S275JR pipes, and why?

A: The pipes undergo a galvanization process, which coats them in a protective layer of zinc. This surface treatment significantly enhances their resistance to corrosion and extends their service life, especially in harsh environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Carbon Steel Pipe Category

Carbon ASTM A672 C65 Pipes

Material : Other, Carbon Steel Grade C65

Technique : Other, Electric Fusion Welded (EFW)

Surface Treatment : Other, Antirust Oil, Varnish Coating, Galvanized

Carbon ASTM A333 Grade 6 Pipes

Minimum Order Quantity : 50 Kilograms

Material : Steel

Technique : Hot Rolled

Warranty : 1 Year

Usage : Industrial

Surface Treatment : Galvanized

Carbon ASTM A672 C65 Pipes

Minimum Order Quantity : 50 Kilograms

Material : Steel

Technique : Hot Rolled

Warranty : 1 Year

Usage : Industrial

ASTM A106 Grade B Pipe

Minimum Order Quantity : 50 Kilograms

Material : Steel

Technique : Hot Rolled

Warranty : 1 Year

Usage : Industrial

Surface Treatment : Galvanized

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese