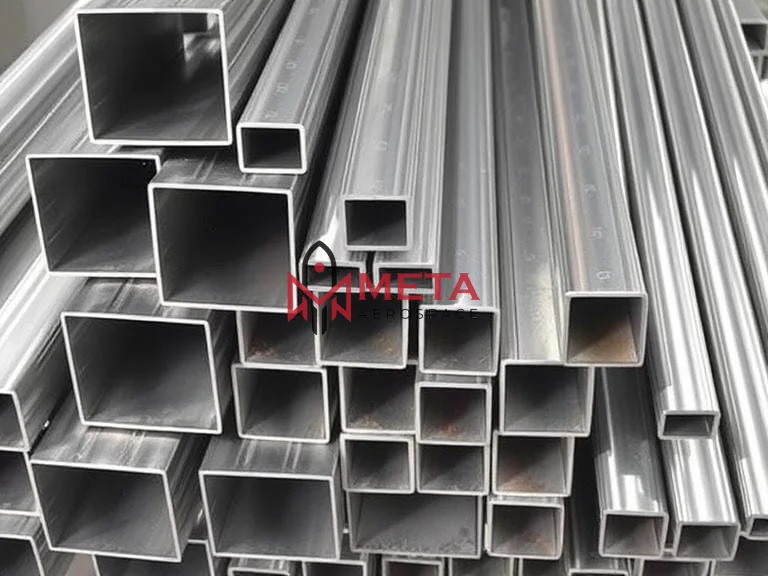

Stainless Steel Square Pipes

Price 265 INR/ Kilograms

MOQ : 50 Kilograms

Stainless Steel Square Pipes Specification

- Usage

- Industrial

- Surface Finish

- Polished

- Application

- Structure Pipe

- Connection

- Welding

- Shape

- Square

- Grade

- SS304

- Technique

- Hot Rolled

- Color

- Sliver

- Warranty

- 1 Year

Stainless Steel Square Pipes Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1 Kilograms Per Week

- Delivery Time

- 1-2 Week

About Stainless Steel Square Pipes

What Are Specification Stainless Steel Square Pipes?

| Stainless Steel Square Pipe Grades | TP - 304/L/H, TP - 316/L/H/Ti, TP - 317L, TP - 321/H, TP - 347/H, 202, JT - 7, J4 - 1, TP - 409/L, TP - 410, TP - 430Ti, TP 439 |

|---|---|

| Stainless Steel Square Pipe Standards | ASTM A249 - A269 - A312 - A358 - A409 - A554 - A778 - A789 - A790 |

| Pipe Size | 12.75 X 12.75, 15 X 15, 20 X 20, 25 X 25, 30 X 30, 40 X 40, 50 X 50, 60 X 60, 75 X 75, 80 X 80, 90 X 90, 100 X100 |

| TOLERANCE on Length | Commercial Length: 6000mm +/- 30mm Fix Length: from 1200 mm up to 12000mm with a tolerance up to -0/+ 5mm |

| Stainless Steel Square Pipe Finish | Polished Grit 120 - 600, Seamless, Welded, Brushed, Pickled, Solution Annealed and Pickled up to O.D. 219.1mm,Mirror Polished |

Chemical Composition Of Stainless Steel Square Pipes?

| STAINLESS STEEL PIPE GRADES | UNS | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Nb | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | ||||

| TP316 | S3160 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

Mechanical Properties Of Stainless Steel Square Pipes?

| Material | Heat | Temperure | Tensile Strength | Yield Strength | Elongation %, Min |

|---|---|---|---|---|---|

| Treatment | Min. | Ksi (MPa), Min. | Ksi (MPa), Min. | ||

| º F(º C) | |||||

| TP304 | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

| TP304L | Solution | 1900 (1040) | 70(485) | 25(170) | 35 |

| TP316 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP316L | Solution | 1900(1040) | 70(485) | 25(170) | 35 |

Premium SS304 Square Pipes for Structural Applications

Designed for industrial usage, our SS304 stainless steel square pipes provide exceptional strength and corrosion resistance. The hot rolled process combined with manual polishing results in a smooth, polished surface that is visually appealing and structurally sound, making these pipes ideal for a range of welded structural pipe applications in demanding environments.

Comprehensive Support and Reliable Delivery across India

As a trusted manufacturer, exporter, supplier, and trader, we ensure prompt service and consistent quality across all orders. Our central manufacturing hub in India allows us to efficiently serve clients nationwide, offering industry-standard products backed by a one-year warranty and dedicated after-sales support.

FAQs of Stainless Steel Square Pipes:

Q: How are the stainless steel square pipes manufactured?

A: These square pipes are produced using the hot rolled technique, which involves rolling high-quality SS304 stainless steel at elevated temperatures. After forming, each pipe is manually polished to achieve a smooth and shiny finish, ideal for structural applications and welding.Q: What makes SS304 grade suitable for industrial usage?

A: SS304 grade stainless steel is known for its corrosion resistance, strength, and long life. These characteristics make it especially suitable for industrial environments where durability and reliability are essential.Q: When should I choose these pipes for my project?

A: These square pipes are perfect for industrial structural projects that require robust materials and a polished surface. They are recommended when you need pipes suitable for welding and capable of withstanding harsh conditions.Q: Where can your stainless steel square pipes be delivered?

A: We serve clients across India and also export globally. Our strong supply chain makes it easy to deliver products efficiently to any required location.Q: What is the benefit of the manual polished finish on these pipes?

A: The manual polished finish provides a smooth, aesthetically pleasing silver surface while enhancing resistance to staining and corrosion, making these pipes ideal for visible and structural applications.Q: How are the pipes typically connected in installations?

A: These pipes are designed for welding connections, ensuring strong joints in structural frameworks and long-lasting installation integrity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Stainless Steel Pipe Category

Stainless Steel 904L Pipes

Minimum Order Quantity : 50 Kilograms

Color : Sliver

Material : Stainless Steel

Connection : Welding

Surface Finish : Polished

Stainless Steel 317 Pipes

Price 650 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Color : Sliver

Material : Stainless Steel

Connection : Welding

Surface Finish : Polished

Stainless Steel 304 Pipe

Price 240.0 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Color : Silver

Material : Stainless Steel

Connection : Welding

Surface Finish : Polished

Stainless Steel 310S Pipes

Minimum Order Quantity : 50 Kilograms

Color : Sliver

Material : Stainless Steel

Connection : Welding

Surface Finish : Polished

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese