Call: 07313726336

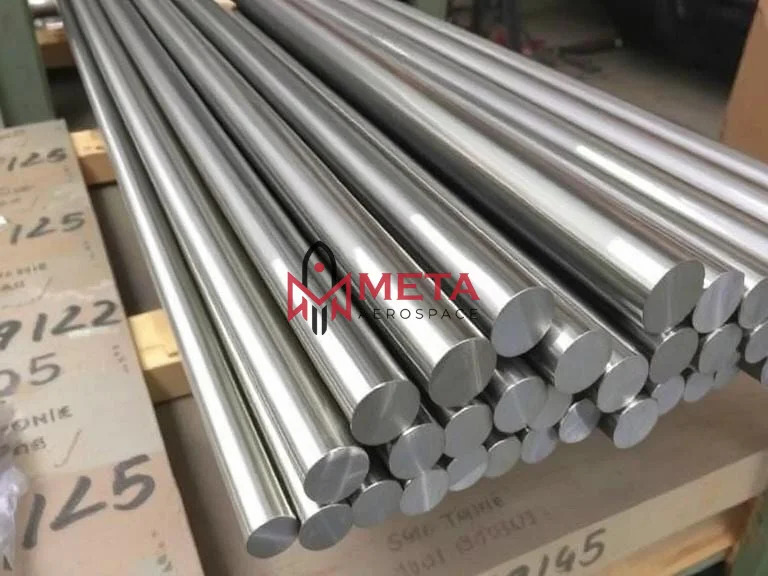

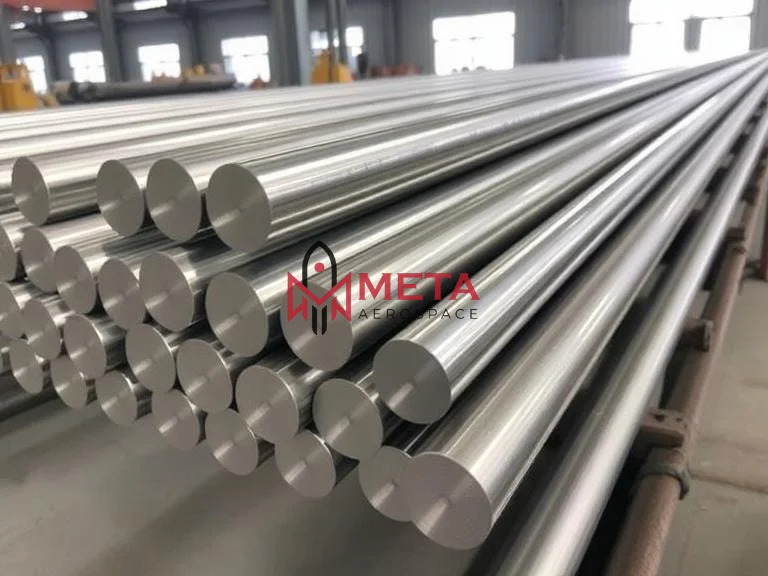

Super Duplex Steel S32760 Round Bars

Super Duplex Steel S32760 Round Bars Specification

- Recyclable

- Yes

- Heat Resistance

- Yes

- Coating Type

- None / As requested

- Material Composition %

- Cr 24-26%, Ni 6-8%, Mo 3-4%, W 0.5-1%, Cu 0.5-1%, N 0.2-0.3%

- Size

- Custom as per requirement

- Product Form

- Solid Bar

- Tensile Strength

- Min 800 MPa

- Diameter

- 6 mm to 250 mm

- Corrosion Resistant

- Excellent (suitable for aggressive environments)

- Hardness

- Max 310 HB

- Product Name

- Super Duplex Steel S32760 Round Bars

- Steel Type

- Super Duplex Stainless Steel

- Steel Product Type

- Round Bars

- Grade

- S32760

- Thickness

- Varies as per specification

- Shape

- Round

- Steel Standard

- ASTM A276, ASTM A479

- Surface

- Bright, Black, Polished

- Composition

- 25% Cr, 7% Ni, 3.6% Mo, 0.28% N, W, Cu

- Application

- Oil & Gas Industry, Chemical Processing, Marine Industry, Power Generation, Desalination Plants

- Dimension (L*W*H)

- Custom as per requirement

- Weight

- As per size and length

- Color

- Silver / Metallic

- Material Grade

- Super Duplex S32760

- Finish Type

- Bright Polish, Matt Finish, Black

- Usage

- Machining, Forging, Construction, Fabrication

- Yield Strength

- Min 550 MPa

- Melting Point

- 1350C - 1420C

- Thermal Conductivity

- Approximately 15 W/m.K at 20C

- Delivery Condition

- Annealed

- Density

- 7.8 g/cm

- Magnetic Properties

- Slightly Magnetic

- Length

- Up to 6 meters or custom cut

- Processing Type

- Hot Rolled / Cold Drawn

- Elongation

- Min 25%

About Super Duplex Steel S32760 Round Bars

What Are Specification Super Duplex Steel S32760 Round Bars?

| Specifications Chart | ASTM A276, ASME SA276 |

|---|---|

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Size in mm | 5 mm To 500 mm |

| Diameter in mm | 0.1 mm to 100 mm |

| Length in mm | 100 mm To 3000 mm Long & Above |

| Surface Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Form | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

Equivalent material Of Super Duplex Steel S32760 Round Bars?

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Super Duplex Steel S32750 | 1.4410 | S32750 |

| Super Duplex Steel S32760 | 1.4501 | S32760 |

Chemical Composition Of Super Duplex Steel S32760 Round Bars?

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| S32750 / S32760 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 26.00 | 3.00 5.00 | 6.00 8.00 | 0.24 0.32 | 58.095 min |

Mechanical Properties Of Super Duplex Steel S32760 Round Bars?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.8 g/cm3 | 1350 C (2460 F) | Psi 80000 , MPa 550 | Psi 116000 , MPa 800 | 15 % |

Exceptional Corrosion and Heat Resistance

Super Duplex Steel S32760 round bars are engineered to withstand aggressive and high-temperature environments. Their excellent corrosion resistance makes them particularly suitable for marine, chemical processing, and desalination plant applications. With a heat resistance up to 300C, they retain mechanical integrity and surface quality even under challenging conditions.

Versatile Manufacturing and Finishing Options

These round bars are manufactured using hot rolled or cold drawn processes, followed by annealing to achieve optimal mechanical properties. The products are available in a variety of finishes, including bright polished, matte, and black, catering to diverse industrial requirements. Customizations in length, diameter, and surface treatments are offered to fulfill specific client needs.

FAQs of Super Duplex Steel S32760 Round Bars:

Q: How are Super Duplex Steel S32760 Round Bars processed and finished?

A: Super Duplex Steel S32760 Round Bars are produced using hot rolled or cold drawn techniques to ensure superior strength and durability. After shaping, the bars are annealed for enhanced toughness. They are available with bright polish, matte, or black finishes, depending on application and customer preference.Q: What applications are Super Duplex Steel S32760 Round Bars best suited for?

A: These round bars are ideal for sectors that demand high corrosion resistance and strength, such as oil & gas, marine, chemical processing, power generation, and desalination plants. Their robust properties enable long-lasting performance in aggressive environments.Q: When should Super Duplex S32760 be considered over standard stainless steels?

A: Super Duplex S32760 should be chosen when exceptional strength, higher resistance to pitting, and stress corrosion are critical. It is particularly effective in situations involving harsh chemicals or seawater, offering superior service life compared to conventional stainless steels.Q: Where can Super Duplex Steel S32760 Round Bars be sourced?

A: These round bars are supplied, exported, and traded by manufacturers and suppliers in India and globally. Custom dimensions and finishes may be requested directly from reputable suppliers or exporters specialized in super duplex stainless steels.Q: What are the main benefits of using Super Duplex Steel S32760 Round Bars?

A: Key benefits include outstanding resistance to chloride-induced corrosion, high mechanical strength, slight magnetism, and excellent durability. Their recyclability and capacity to handle demanding operational environments make them a sustainable and efficient choice.Q: How are the dimensions and weight of Super Duplex S32760 Round Bars determined?

A: Dimensions such as length, width, height, and diameter are fully customizable as per the clients specifications. The weight is calculated based on the selected size and length according to the standardized density of 7.8 g/cm.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Super And Duplex Steel Bars Category

Super Duplex Steel S32750 Round Bars

Steel Type : Other, Super Duplex Stainless Steel

Grade : S32750

Steel Standard : Other, ASTM A276, ASTM A479

Corrosion Resistant : Excellent

Hardness : 293 HB max

Duplex Steel S31803 Bar

Minimum Order Quantity : 50 Kilograms

Steel Type : Stainless Steel

Grade : Various Grades Available

Steel Standard : AISI

Corrosion Resistant : Yes

Hardness : Rigid

Duplex Steel S32205 Bar

Minimum Order Quantity : 50 Kilograms

Steel Type : Stainless Steel

Grade : Various Grades Available

Steel Standard : AISI

Corrosion Resistant : Yes

Hardness : Rigid

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese