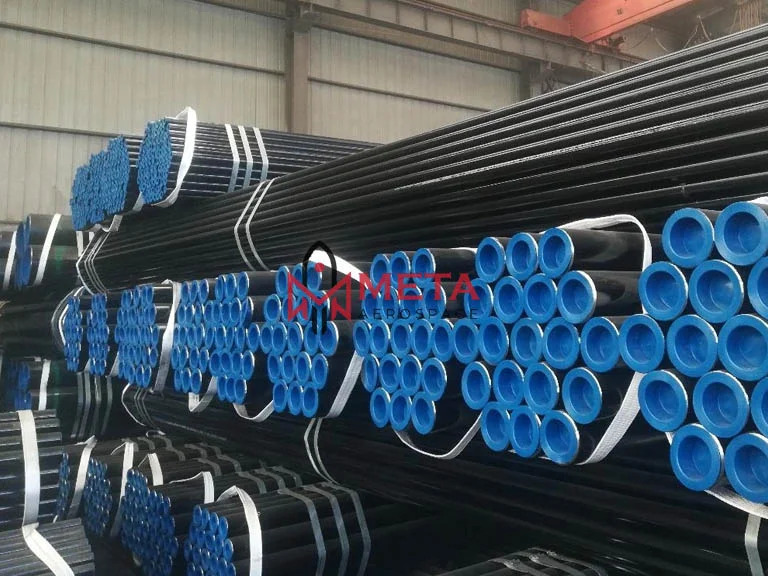

API 5CT L80N80 Pipe

API 5CT L80N80 Pipe Specification

- Diameter

- 2 3/8 to 20

- Sealing Type

- Metal-to-Metal Seal

- Tensile Strength

- 655862 MPa

- Thread Type

- NPT, BTC, LTC, STC

- Tolerance

- 0.5% of specified dimension

- Temperature Range

- -29C to 110C

- Yield Strength

- 552758 MPa

- Connection Type

- Threaded

- Flexibility

- Rigid

- Coating Type

- Internal & External Anticorrosion Coated

- Product Type

- Casing and Tubing Pipe

- Material

- Carbon Steel

- Connection

- API Threaded & Coupled

- Shape

- Round

- Standard

- API 5CT

- Surface Treatment

- Phosphated, Oiled, or Bare

- Outer Diameter

- 60.32 mm 508 mm

- Section Shape

- Circular

- Length

- R1 (4.88-7.62 m), R2 (7.62-10.36 m), R3 (10.36-14.63 m)

- Thickness

- 5.21 mm 16.13 mm

- Color

- Black

- Usage

- Oil and Gas Industry

- Rated Pressure

- Up to 7,600 psi (varies by size/grade)

- Material Grade

- L80, N80

- Application

- Well Casing, Oil & Gas Transportation

- Packing

- Bundled or Loose as Client Request

- Hydrostatic Test

- 100% tested

- Marking

- API Monogram and Heat Number marked

- Hardness

- 23-25 HRC (for L80)

- Rust Resistance

- Enhanced by Surface Treatment

- Ends

- Plain End, Threaded & Coupled

- NDT

- Ultrasonic & Eddy Current Tested

- Internal Diameter Tolerance

- Specified as per API 5CT

- Impact Test

- Conducted as per API standards

- Manufacturing Process

- Hot Rolled & Seamless

- Straightness

- 0.2% Max of total length

About API 5CT L80N80 Pipe

What Are Specification API 5CT L80/N80 Pipes?

| Product Specification Level (PSL) |

|

|---|---|

| X46 Grade PSL2 Pipe Standard | API 5CT L80/N80 (Specification for API 5L Grade X46 PSL1 Line Pipe - ANSI/API specification 5L - 44th Edition, October 1, 2007) |

| 5L X46 Steel Pipe Sizes | Nominal API 5L Grade X46 PSL1 Pipe Size 1/2" to 48 " O.D. API 5CT L80/N80 Pipes Wall Thickness - Schedule 10 through 160, STD, XS, XXS. |

| X46 Carbon Steel Pipe Origin | Indian Origin, Japanese Origin, Korean Origin, European Origin, US Origin, Ukraine Origin, Russian Origin |

| Grade X46 Pipe Thickness | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XS, SCH XXS, All API 5CT L80/N80 Pipes Wall Thickness available in stock |

| X46 PSL1 Pipe Type | Seamless / ERW / Welded / Fabricated / CDW |

| X46 PSL2 Pipe End | Plain, Bevel, Screwed, Threaded |

| L320 X46 Pipe Length | Single Random, Double Random & Required Length, Custom Size - 12 Meter lengths |

| Testing and Inspection Reports | EN 10204 3.1, Mill TC EN 10204 3.1, Visual Inspection Reports, Third Party Inspection Reports, Destructive Test Report, PMI Test Reports, Non Destructive Test Reports, NABL Approved Lab, Chemical and Mechanical Reports, India Boiler Regulations (IBR) Test Certificate |

| X46 Grade PSL1 Pipe Packing | API 5CT L80/N80 Gr B Pipe Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| API 5L Gr X46 Pipe Finishes | Bare, Oiled, Mill Varnish, Galv, FBE, FBE Dual, 3LPE, 3LPP, Coal Tar, Concrete Coating and Tape Wrap HIC Tested X46 Pipe API 5CT L80/N80 PSL1 Pipe End Finishes: Beveled, Square Cut, Threaded & Coupled. |

| Steel X46 Pipe Application & uses | Grade X46 PSL2 Pipe Suitable for Conveying gas, water, oil, and other liquefied media in Oil Refineries, Petrochemicals, Steel, Sugar, Boiler Equipments, Pressure Vessels, Power Generation (Nuclear/Thermal) and General Engineering Purposes |

| Other manufacturers of API 5L Gr X46 Seamless steel pipe | MSL, JSL, ISMT, USL, BAO, Lontrin, SMTM, TNRS, V&M and Wuxi |

| BS EN 10208-2:2009 | X46 Grade PSL1 pipelines for combustible fluids. Suitable to use in maximum operating pressure over 16 bar. |

| Value added service for API 5L Grade X46 PSL2 Pipe |

|

Chemical Composition Of API 5CT L80/N80 Pipes?

| Grade | C | Si | Mn | P | S | Cr | Ni | Cu | Als |

|---|---|---|---|---|---|---|---|---|---|

| API 5CT L80 | 0.15-0.22 | 1.00 | 0.25-1.00 | 0.020 | 0.010 | 12.0-14.0 | 0.20 | 0.20 | 0.020 |

Mechanical Properties Of API 5CT L80/N80 Pipes?

| Steel Grade | Yield Strength (Mpa) | Tensile Strength (Mpa) |

|---|---|---|

| API 5CT L80 | 552-655 | 655 |

Precision and Strength for Demanding Applications

Engineered to surpass industry benchmarks, API 5CT L80/N80 pipes offer impressive tensile and yield strength, combined with controlled hardness and exacting dimensional tolerances. Their robust construction and reliable threading options, including NPT, BTC, LTC, and STC, make them adaptable for use in a variety of oil and gas projects, ensuring secure installation and operational integrity.

Comprehensive Testing and Advanced Surface Protection

Each pipe undergoes thorough hydrostatic testing and non-destructive inspection methods such as ultrasonic and eddy current testing for maximum reliability. Enhanced rust resistance is achieved through advanced surface treatments like phosphating and oiling, along with internal and external anticorrosion coatings, making these pipes suitable for harsh environments and prolonging service life.

Versatility in Supply and Customization

Supplied by reputable exporters, manufacturers, suppliers, and traders in India, these pipes accommodate a wide range of project requirements. Available in multiple diameters, thicknesses, and connection types, clients can request customized packing and shape preferences, ensuring efficient handling and seamless integration within existing oil and gas infrastructure.

FAQs of API 5CT L80N80 Pipe:

Q: How are API 5CT L80/N80 pipes manufactured to ensure quality and durability?

A: API 5CT L80/N80 pipes are produced using a hot rolled, seamless process to achieve high strength and uniform microstructure. Each pipe is rigorously tested through hydrostatic, ultrasonic, and eddy current methods, and meets API 5CT specifications for dimensional tolerance, hardness, and impact resistance, ensuring reliability and long operational life in oil and gas applications.Q: What are the main applications for these pipes in the oil and gas industry?

A: The pipes are predominantly used for well casing and oil & gas transportation systems. Their robust construction, high tensile strength, and corrosion-resistant coatings make them ideal for use in challenging environments, safeguarding the integrity of subsurface and surface fluid handling operations.Q: When should I opt for L80 versus N80 material grades?

A: L80 and N80 are both API 5CT-certified grades suitable for oil and gas wells. L80 pipes offer moderate corrosion resistance with a specified hardness, often preferred when well conditions require slightly higher resistance to stress and sour gas environments. N80 is generally chosen for environments where such specific corrosion resistance is not critical.Q: Where are these API 5CT pipes typically manufactured and supplied from?

A: These pipes are primarily manufactured and supplied by Indian exporters, manufacturers, and suppliers. They are distributed worldwide, serving both national and international oil and gas industry projects, thanks to Indias established capacity for producing high-grade carbon steel pipe products.Q: What benefits do enhanced rust resistance and surface treatments provide?

A: Surface treatments such as phosphating and oiling, along with internal and external anticorrosion coatings, significantly improve the pipes longevity by preventing rust, corrosion, and wear. This ensures reliable performance in harsh environments and reduces maintenance intervals for field operators.Q: How do you ensure correct pipe selection for specific project requirements?

A: Selection is based on key parameters such as material grade (L80 or N80), exterior diameter, thickness, length, pressure rating, and required thread connection type. Detailed marking (API Monogram and heat number) and adherence to API 5CT standards help ensure transparency and suitability for project specifications.Q: What are the advantages of using API 5CT threaded and coupled pipe connections?

A: Threaded and coupled (T&C) connections allow secure, leak-proof joining of pipes, ensuring stable installation in wells. With options like NPT, BTC, LTC, and STC thread types, these connections facilitate versatile usage and reliable performance under high pressure and diverse operating conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in API 5L Pipe Category

API 5L X65 Pipes

Material : Carbon Steel

Surface Treatment : Other, Black Painted, Bare, 3LPE/3LPP Coated, FBE Coated, Anticorrosion Oil

Material Grade : X65

Standard : Other, API 5L

Usage : Oil & Gas Transmission, Pipeline

API 5L X70 Pipes

Material : Carbon Steel

Surface Treatment : Other, Black Painted, Oiled, 3LPE Coated, or bare

Material Grade : X70

Standard : Other, API 5L

Usage : Oil, Gas, Water supply, Structural

API 5L X60 Pipes

Material : Carbon Steel

Surface Treatment : Other, Black Painted, Bare, 3LPE Coated, Varnished, Galvanized

Material Grade : API 5L X60

Standard : Other, API 5L

Usage : Oil & Gas Transportation, Petrochemical, Water Supply

API 5L ERW Pipes

Material : Carbon Steel

Surface Treatment : Other, Black Painting, Anticorrosion Coated, Oiled

Material Grade : Gr. B, X42, X52, X60, X65, X70

Standard : Other, API 5L

Usage : Oil & Gas, Water Transmission, Structural

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese