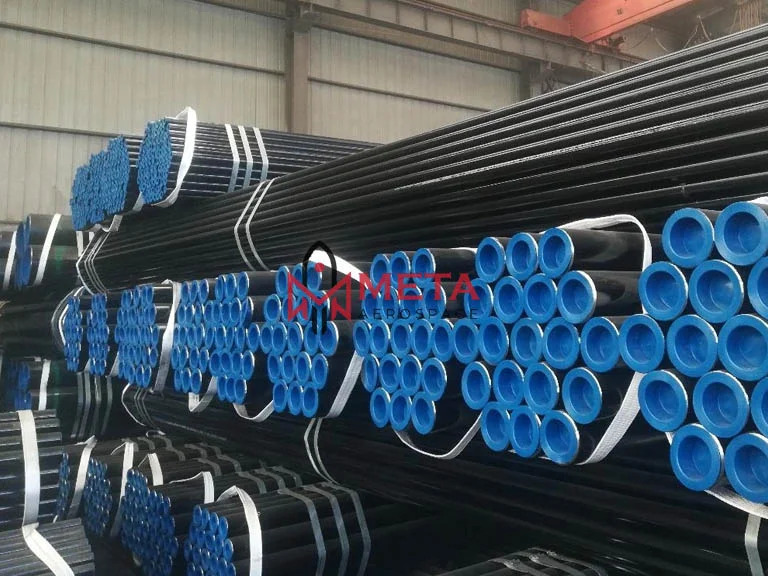

API 5L ERW Pipes

API 5L ERW Pipes Specification

- Yield Strength

- 245 MPa minimum

- Diameter

- 21.3 mm to 610 mm

- Coating Type

- 3LPE, FBE, Black Paint

- Connection Type

- Welded

- Temperature Range

- -29C to 121C

- Tensile Strength

- 415 MPa minimum

- Flexibility

- Rigid

- Thread Type

- Plain End, Beveled End

- Tolerance

- 0.75 mm

- Product Type

- ERW Pipe

- Material

- Carbon Steel

- Connection

- Welded

- Shape

- Round

- Standard

- API 5L

- Surface Treatment

- Black Painting, Anti-corrosion Coated, Oiled

- Outer Diameter

- 21.3 mm to 610 mm

- Section Shape

- Cylindrical

- Length

- Up to 12 meters

- Thickness

- 4 mm to 20 mm

- Color

- Black

- Usage

- Oil & Gas, Water Transmission, Structural

- Rated Pressure

- Up to 20 MPa

- Application

- Pipeline, Construction, Water Supply

- Material Grade

- Gr. B, X42, X52, X60, X65, X70

- Pipe Ends

- Plain End, Beveled End

- Heat Treatment

- Normalized, Stress Relieved

- Marking

- Standard & Custom Marking Available

- Manufacturing Process

- Electric Resistance Welded (ERW)

- Packaging Type

- Bundled, Plastic Caps, Waterproof Packaging

- Inspection

- Third Party Inspection Accepted

- Impact Testing

- As per API 5L requirements

- Custom Sizes

- Available on Request

About API 5L ERW Pipes

What Are Specification API 5L ERW Pipes?

| API 5L Grade b erw pipe Standard | API 5L ERW (Specification for ERW Line Pipe - ANSI/API specification 5L - 44th Edition, October 1, 2007) |

|---|---|

| Grade | GR A, GR B, X42, X46, X52, X56, X60, X65, X70, S275, S355 |

| Erw Steel Pipe API 5L Sizes | Nominal ERW Pipe Size 1/2" to 48 " O.D. API 5L ERW Pipes Wall Thickness - Schedule 10 through 160, STD, XS, XXS. |

| Product Specification Level (PSL) |

|

| API 5L B Erw pipe Origin | Indian Origin, Japanese Origin, Korean Origin, European Origin, US Origin, Ukraine Origin, Russian Origin |

| API 5L Gr B Erw Thickness | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XS, SCH XXS, All API 5L ERW Pipes Wall Thickness available in stock |

| API 5L Gr B Erw Pipes End | Plain, Bevel, Screwed, Threaded |

| Type | Seamless / ERW / Welded / Fabricated / CDW |

| Length | Single Random, Double Random & Required Length, Custom Size - 12 Meter lengths |

| Testing and Inspection Reports | EN 10204 3.1, Mill TC EN 10204 3.1, Visual Inspection Reports, Third Party Inspection Reports, Destructive Test Report, PMI Test Reports, Non Destructive Test Reports, NABL Approved Lab, Chemical and Mechanical Reports, India Boiler Regulations (IBR) Test Certificate |

| Packing | ERW Pipe Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests |

| API 5L Gr B Erw Finishes | Bare, Oiled, Mill Varnish, Galv, FBE, FBE Dual, 3LPE, 3LPP, Coal Tar, Concrete Coating and Tape Wrap ERW Pipe ERW Pipe End Finishes: Beveled, Square Cut, Threaded & Coupled. |

| API 5L Gr B Erw Pipes Application & uses | ERW Pipe Suitable for Conveying gas, water, oil, and other liquefied media in Oil Refineries, Petrochemicals, Steel, Sugar, Boiler Equipments, Pressure Vessels, Power Generation (Nuclear/Thermal) and General Engineering Purposes |

| Other manufacturers | MSL, JSL, ISMT, USL, BAO, Lontrin, SMTM, TNRS, V&M and Wuxi |

| BS EN 10208-2:2009 | ERW pipelines for combustible fluids. Suitable to use in maximum operating pressure over 16 bar. |

| Value added service |

|

Chemical Composition Of API 5L ERW Pipes?

| ERW PSL1 | ERW PSL2 | |||||||

|---|---|---|---|---|---|---|---|---|

| Grade | C (Max.) | Mn (Max.) | P (Max.) | S (Max.) | C (Max.) | Mn (Max.) | P (Max.) | S (Max.) |

A | 0.22 | 0.90 | 0.03 | 0.03 | 0.22 | 1.20 | 0.025 | 0.015 |

B | 0.26 | 1.20 | 0.03 | 0.03 | 0.22 | 1.30 | 0.025 | 0.015 |

X42 | 0.26 | 1.30 | 0.03 | 0.03 | 0.22 | 1.40 | 0.025 | 0.015 |

X46 | 0.26 | 1.40 | 0.03 | 0.03 | 0.22 | 1.40 | 0.025 | 0.015 |

X52 | 0.26 | 1.40 | 0.03 | 0.03 | 0.22 | 1.40 | 0.025 | 0.015 |

X56 | 0.26 | 1.40 | 0.03 | 0.03 | 0.22 | 1.40 | 0.025 | 0.015 |

X60 | 0.26 | 1.40 | 0.03 | 0.03 | 0.22 | 1.45 | 0.025 | 0.015 |

X65 | 0.26 | 1.45 | 0.03 | 0.03 | 0.22 | 1.65 | 0.025 | 0.015 |

X70 | 0.26 | 1.65 | 0.03 | 0.03 | 0.22 | 1.85 | 0.025 | 0.015 |

Mechanical Properties Of API 5L ERW Pipes?

| Pipe Grade | Tensile Properties - ERW Pipe Body of SMLS and Welded Pipes PSL 1 | Seam of ERW Welded Pipe | ||

|---|---|---|---|---|

| Yield Strength a | Tensile Strength a | Elongation | Tensile Strength b | |

| Rt0,5 PSI Min | Rm PSI Min | (in 2in Af % min) | Rm PSI Min | |

| A | 30,500 | 48,600 | c | 48,600 |

| B | 35,500 | 60,200 | c | 60,200 |

| X42 | 42,100 | 60,200 | c | 60,200 |

| X46 | 46,400 | 63,100 | c | 63,100 |

| X52 | 52,200 | 66,700 | c | 66,700 |

| X56 | 56,600 | 71,100 | c | 71,100 |

| X60 | 60,200 | 75,400 | c | 75,400 |

| X65 | 65,300 | 77,500 | c | 77,500 |

| X70 | 70,300 | 82,700 | c | 82,700 |

Precision Manufacturing & Quality Control

Our API 5L ERW Pipes are made using state-of-the-art Electric Resistance Welded technology, ensuring consistent weld strength and dimensional accuracy. Each pipe undergoes stringent third-party inspections and impact testing, adhering to API 5L standards. Heat treatment processes like normalization and stress relieving enhance their durability and integrity, making them ideal for high-pressure and temperature applications.

Versatile Sizes and Tailored Solutions

Choose from a wide outer diameter range of 21.3 mm to 610 mm, lengths up to 12 meters, and thicknesses between 4 mm and 20 mm. We also offer custom sizes to meet specific project requirements. With flexible end options (plain or beveled), various grades, and tailored surface treatments, these pipes are suitable for multiple sectors including construction, water supply, and pipeline infrastructure.

Reliable Protection & Packaging

Our pipes are safely transported in bundled, waterproof packaging with plastic caps to prevent damage. External anti-corrosion coatings like 3LPE, FBE, or black paint provide long-term protection against harsh environmental factors. Standard and custom markings are available for easy tracking and compliance.

FAQs of API 5L ERW Pipes:

Q: How are API 5L ERW Pipes manufactured and what quality inspections are performed?

A: API 5L ERW Pipes are produced using the Electric Resistance Welded (ERW) process, where steel coils are longitudinally welded without the use of filler material. Each pipe is subject to strict third-party inspection and must pass impact testing as per API 5L requirements to ensure reliability and safety in demanding applications.Q: What applications are API 5L ERW Pipes suitable for?

A: These pipes are engineered for use in oil & gas transmission, water supply systems, structural projects, and construction pipelines. With their high mechanical strength, corrosion resistance, and ability to withstand pressures up to 20 MPa, they are ideal for both underground and above-ground installations.Q: When should I opt for custom sizes or specific grades of API 5L ERW Pipes?

A: Opt for custom sizes or specific grades like Gr. B, X42, X52, X60, X65, or X70 when your project requires unique dimensions or enhanced mechanical properties. Customization ensures the pipe fits your technical requirements and operational conditions seamlessly.Q: Where can these pipes be used considering their temperature and pressure ratings?

A: API 5L ERW Pipes can safely be used in environments with temperatures ranging from -29C to 121C and under pressures up to 20 MPa. This makes them perfect for high-demand applications in pipeline infrastructure, construction, and industrial water or gas transportation.Q: What packaging and marking options are provided for safe transport and traceability?

A: Pipes are supplied in bundled packaging with the addition of plastic caps and waterproof wrapping to prevent damage during transit. Standard and custom markings are available, ensuring each pipe can be easily traced and identified according to client or project requirements.Q: How does surface treatment benefit API 5L ERW Pipes?

A: Surface treatments, including options like black painting, FBE, and 3LPE coatings, significantly improve resistance to environmental corrosion. These protective layers extend the lifespan of pipes, making them ideal for use in challenging conditions, whether buried or exposed.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in API 5L Pipe Category

API 5L X70 Pipes

Usage : Oil, Gas, Water supply, Structural

Material Grade : X70

Material : Carbon Steel

Standard : Other, API 5L

Connection : Other, Beveled, Threaded, Plain End

API 5L X65 Pipes

Usage : Oil & Gas Transmission, Pipeline

Material Grade : X65

Material : Carbon Steel

Standard : Other, API 5L

Connection : Other, Plain End, Beveled End, Threaded

API 5CT L80N80 Pipe

Usage : Oil and Gas Industry

Material Grade : L80, N80

Material : Carbon Steel

Standard : Other, API 5CT

Connection : Other, API Threaded & Coupled

API 5L X46 Pipe

Minimum Order Quantity : 50 Kilograms

Usage : Industrial

Material Grade : Multiple Grades Available

Material : Nickel

Standard : AISI

Connection : Welding

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese