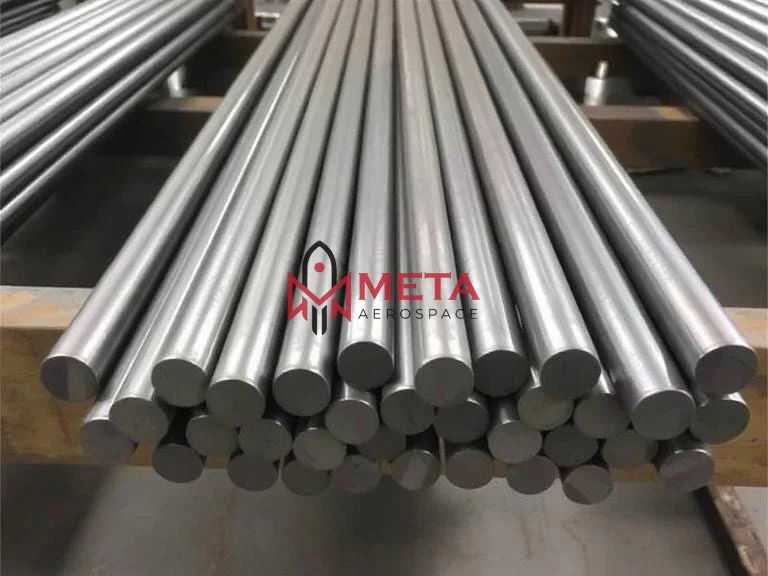

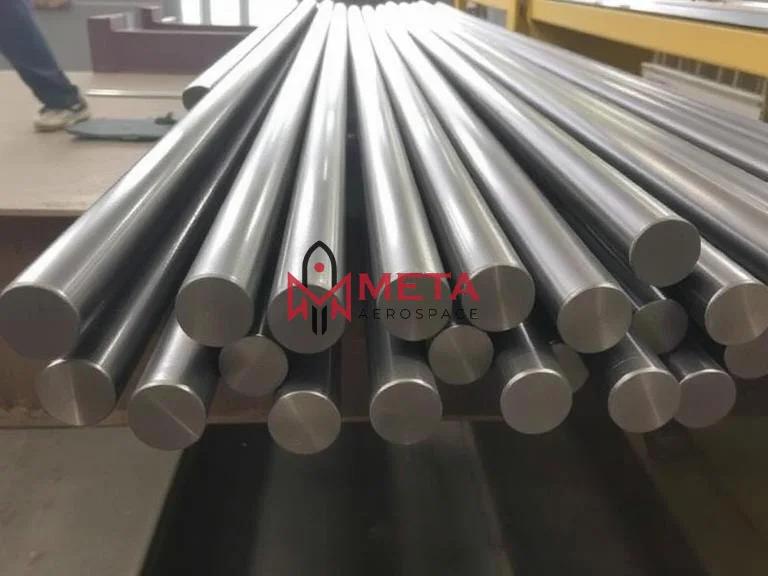

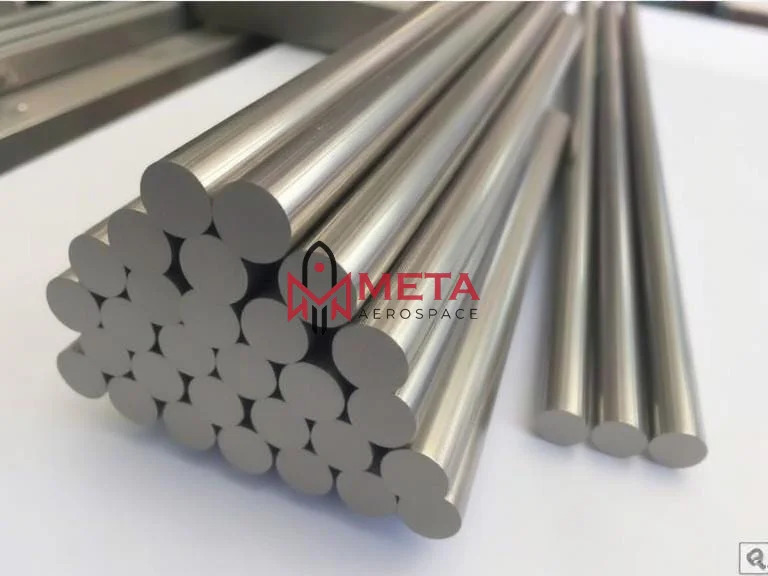

ASTM A182 Gr F91 Alloy Steel Bars

ASTM A182 Gr F91 Alloy Steel Bars Specification

- Tensile Strength

- 585 MPa min

- Product Form

- Solid Bars

- Recyclable

- Yes

- Heat Resistance

- Yes

- Diameter

- 10 mm to 250 mm

- Corrosion Resistant

- Moderate corrosion resistance

- Material Composition %

- Cr: 8-9%, Mo: 0.85-1.05%, V: 0.18-0.25%, C: 0.07-0.13%, Mn: 0.30-0.60%, Si: 0.20-0.50%

- Coating Type

- Uncoated / as requested

- Size

- Customized

- Hardness

- Maximum 250 HB

- Product Name

- ASTM A182 Gr F91 Alloy Steel Bars

- Steel Type

- Alloy Steel

- Steel Product Type

- Bars

- Grade

- F91

- Thickness

- Range: 5 mm to 250 mm

- Shape

- Round, Square, Hexagonal

- Steel Standard

- ASTM A182

- Surface

- Bright, Black, Polished

- Composition

- Cr-Mo-V Alloy (Chromium, Molybdenum, Vanadium)

- Application

- Power generation, petrochemical, oil & gas, boilers, heat exchangers

- Dimension (L*W*H)

- Custom as per requirement

- Weight

- As specified / per order

- Color

- Metallic Gray

- Material Grade

- F91

- Finish Type

- Polished / As rolled

- Usage

- Industrial engineering, high temperature service

- Minimum Order Quantity

- As per requirement

- Impact Value

- Longitudinal 40 J min at room temperature

- Elongation

- 15% min

- Non-Magnetic

- No

- Machinability

- Good

- Weldability

- Good, with preheating recommended

- Approved for

- Power plant piping, pressure vessels

- Stock Availability

- Ready stock available

- Maximum Service Temperature

- Up to 600°C

- Packing Details

- Standard export packing

- Delivery Condition

- Normalized and tempered

- Standard Length

- 5 to 6 meters or cut length

- Heat Treatment

- Quenched and tempered

About ASTM A182 Gr F91 Alloy Steel Bars

What Are Specification ASTM A182 Gr F91 Alloy Steel Bars?

| Specification : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

|---|---|

| Standard Specification : | ASTM A182 / ASME SA182 |

| Size : | 5mm to 500mm Dia in 100mm to 6000mm Length |

| Thickness : | 0.5mm to 500mm Diameter |

| Diameter : | 10 mm To 200 mm |

| Length : | 1000 mm Long To 6000 mm Long |

| Form : | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

Equivalent material Of ASTM A182 Gr F91 Alloy Steel Bars?

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| ASTM A182 F91 | 1.4903 | - |

Chemical Composition Of ASTM A182 Gr F91 Alloy Steel Bars?

| Grade | C | Mn | Si | Mo | P | Cr |

|---|---|---|---|---|---|---|

| ASTM A182 F91 | 0.08 - 0.15 | 0.30 - 0.60 | 0.20 - 0.50 | 0.85 - 1.05 | 0.020 | 8.0 - 9.5 |

Mechanical Properties Of ASTM A182 Gr F91 Alloy Steel Bars?

| Tensile Strength (ksi) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (ksi) min |

|---|---|---|

| 570 | 23 | 295 |

Superior Heat and Strength Performance

ASTM A182 Gr F91 Alloy Steel Bars are engineered to withstand intense heat and high-pressure environments, making them ideal for use in power plant piping, pressure vessels, and high-temperature service applications. The advanced Cr-Mo-V alloy composition ensures reliability up to 600C, delivering consistent mechanical properties, including high impact value and minimum 15% elongation, for demanding operations.

Versatile Applications Across Industries

These alloy steel bars address the needs of a wide range of industries, such as power generation, petrochemical, oil and gas, and industrial engineering. Their availability in multiple shapes, sizes, and finishes means they can be tailored for critical systems including boilers and heat exchangers, ensuring durability and optimal performance under challenging conditions.

FAQs of ASTM A182 Gr F91 Alloy Steel Bars:

Q: How are ASTM A182 Gr F91 Alloy Steel Bars typically delivered?

A: These bars are supplied in a normalized and tempered condition, ensuring optimal mechanical properties for industrial use. Standard export packing is used to protect the product during transit, and bars can be provided in standard lengths of 5 to 6 meters or as cut-to-length, depending on customer requirements.Q: What are the key benefits of using ASTM A182 Gr F91 Alloy Steel Bars?

A: The main advantages include excellent strength at high temperatures, good machinability, reliable weldability (with preheating recommended), moderate corrosion resistance, and high impact value (40 J min at room temperature). Their robust composition and versatile finishes make them suitable for critical and high-stress engineering applications.Q: When is it recommended to use these alloy steel bars in engineering projects?

A: ASTM A182 Gr F91 bars are particularly suited for applications involving continuous operation at elevated temperatures, such as power plant piping, boilers, heat exchangers, and pressure vessels in the power generation, petrochemical, and oil & gas sectors.Q: Where can these bars be sourced and in what forms are they available?

A: These bars are manufactured, exported, and supplied from India, with ready stock available for fast delivery. Customers can order round, square, or hexagonal solid bars in various diameters and thicknesses, finished bright, black, or polished, as required.Q: What is the standard process for heat treatment of these bars?

A: ASTM A182 Gr F91 Alloy Steel Bars are heat treated by quenching and tempering, followed by normalization. This process ensures they achieve the target tensile strength, hardness (max 250 HB), and durability required for demanding industrial applications.Q: How should these alloy steel bars be machined and welded?

A: The bars offer good machinability, allowing for precise shaping and finishing. For welding, preheating is advised to ensure proper fusion and to minimize thermal stress, maintaining the mechanical properties and structural integrity of the material.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Alloy Steel Bar Category

AISI 4140 Gr F91 Alloy Steel Bars

Steel Standard : Other, ASTM A182/F91, AISI 4140

Hardness : 180250 HB

Surface : Bright, Black, Polished

Corrosion Resistant : Yes, with proper surface protection

Grade : AISI 4140 Gr F91

ASTM A182 Gr F5 Alloy Steel Bars

Steel Standard : Other, ASTM A182

Hardness : 183235 HB (Brinell Hardness)

Surface : Bright, Black, Polished

Corrosion Resistant : Moderate, suitable for certain applications

Grade : ASTM A182 Gr F5

ASTM A182 Gr F22 Alloy Steel Bars

Steel Standard : Other, ASTM A182

Hardness : 217 HB max (annealed)

Surface : Bright, Black, Polished, Peeled, Turned, Ground, Rough Machined

Corrosion Resistant : Moderate

Grade : Gr F22

ASTM A182 Gr F9 Alloy Steel Bars

Steel Standard : Other, ASTM A182

Hardness : 223 HBW (as per standard)

Surface : Bright, Black, Rough Turned, Peeled, Polished

Corrosion Resistant : Good

Grade : F9

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese