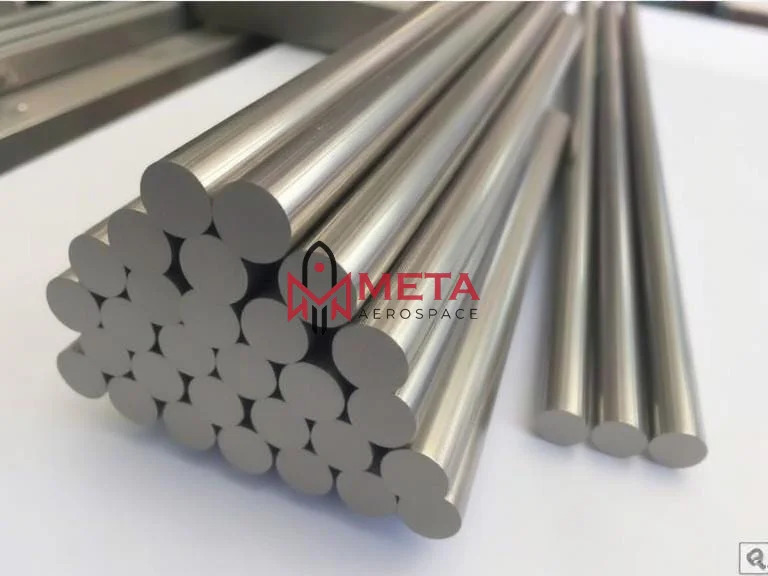

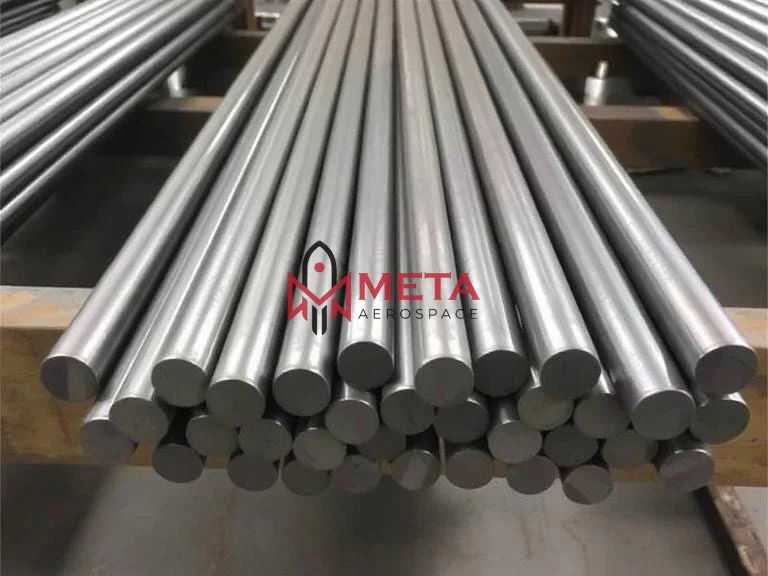

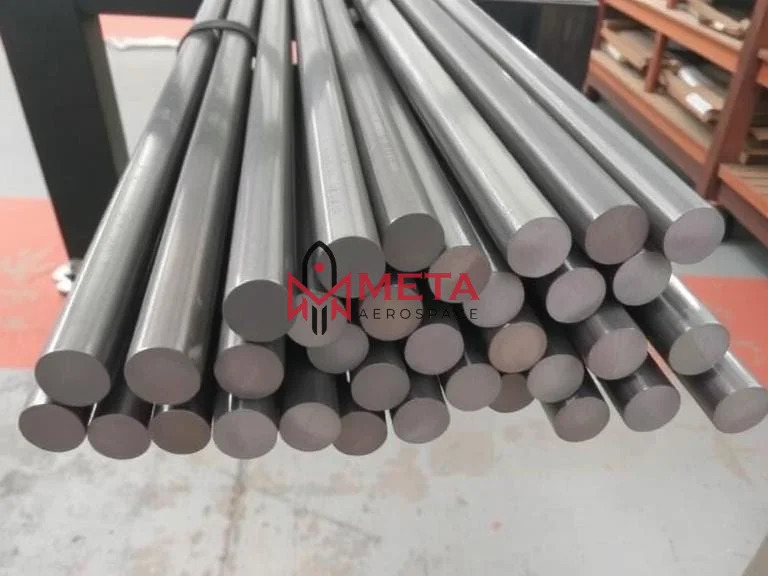

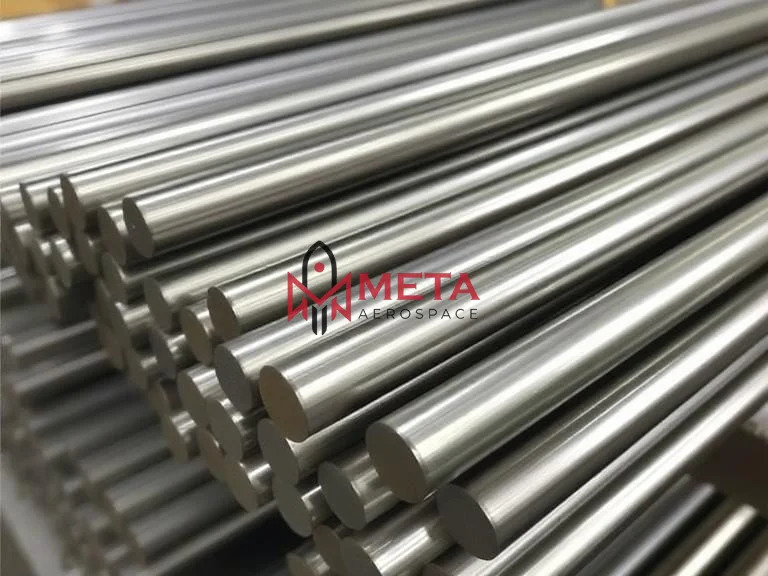

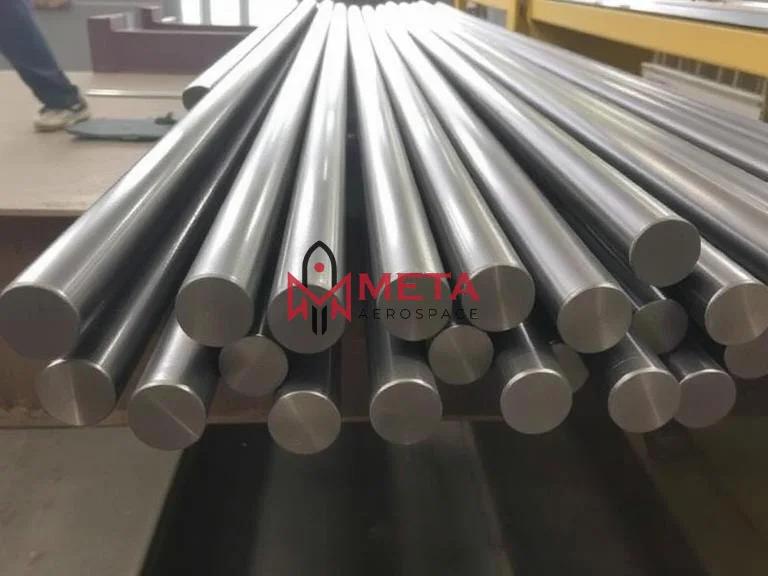

ASTM A182 Gr F9 Alloy Steel Bars

ASTM A182 Gr F9 Alloy Steel Bars Specification

- Recyclable

- Yes

- Diameter

- 6mm to 350mm

- Hardness

- 223 HBW (as per standard)

- Material Composition %

- C: 0.15 max, Mn: 0.60 max, Si: 0.50 max, Cr: 8.0-10.0, Mo: 0.90-1.10, P: 0.030 max, S: 0.030 max, V: 0.18-0.25

- Coating Type

- Uncoated / As specified

- Corrosion Resistant

- Good

- Heat Resistance

- Yes

- Tensile Strength

- 415 MPa min

- Product Form

- Forged/Rolled Bars

- Size

- Custom / As per order

- Product Name

- ASTM A182 Gr F9 Alloy Steel Bars

- Steel Type

- Alloy Steel

- Steel Product Type

- Bars

- Grade

- F9

- Thickness

- Custom / As required

- Shape

- Round, Square, Hexagonal

- Steel Standard

- ASTM A182

- Surface

- Bright, Black, Rough Turned, Peeled, Polished

- Composition

- Chromium-Molybdenum-Vanadium Alloy Steel

- Application

- Industrial, Petrochemical, Power Generation, Oil & Gas, Engineering Applications

- Dimension (L*W*H)

- Custom / As per requirement

- Weight

- Varies as per size and length

- Color

- Natural Metallic Grey

- Material Grade

- ASTM A182 Gr F9

- Finish Type

- Bright, Black, Polished

- Usage

- Manufacturing of flanges, valves, and components for high temperature services

- Manufacturing Process

- Hot Rolled/Forged & Heat Treated

- Lead Time

- Depends on order quantity

- Machinability

- Good

- Length

- 1 meter to 6 meters or as required

- Impact Strength

- As per standard requirements

- Packing

- Standard Export Packaging, Bundled or Loose

- Standard Specification

- ASTM, ASME, DIN, EN, BS, IS

- Testing

- Ultrasonic, Hardness, Chemical & Mechanical Test certificates provided

- Minimum Order Quantity

- Negotiable / As per contract

About ASTM A182 Gr F9 Alloy Steel Bars

What Are Specification ASTM A182 Gr F9 Alloy Steel Bars?

| Specification : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

|---|---|

| Standard Specification : | ASTM A182 / ASME SA182 |

| Size : | 5mm to 500mm Dia in 100mm to 6000mm Length |

| Thickness : | 0.5mm to 500mm Diameter |

| Diameter : | 10 mm To 200 mm |

| Length : | 1000 mm Long To 6000 mm Long |

| Form : | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

Chemical Composition Of ASTM A182 Gr F9 Alloy Steel Bars?

| Grade | C | Mn | Si | Mo | Others |

|---|---|---|---|---|---|

| ASTM A182 F9 | 0.16 | 0.60 | 0.40 max | 0.30 | max. Cu = 0.30 |

Mechanical Properties Of ASTM A182 Gr F9 Alloy Steel Bars?

| Grade | Tensile Strength (ksi) min | Elongation (% in 50mm) min | Yield Strength 0.2% Proof (ksi) min | Hardness |

|---|---|---|---|---|

| ASTM A182 F9 | 415 | 30 | 205 | - |

Superior Strength and Reliability

ASTM A182 Gr F9 Alloy Steel Bars are renowned for their high tensile strength, with a minimum of 415 MPa, ensuring reliability in critical environments. Their controlled composition and thorough testing make them a preferred choice for heavy-duty applications, especially where both mechanical performance and durability are paramount.

Versatile Manufacturing Capabilities

These alloy steel bars are available in a wide range of diameters from 6mm to 350mm and customizable shapes such as round, square, and hexagonal. Manufactured using hot-rolled or forged processes and heat treated for enhanced mechanical properties, they can be finished bright, black, or polished as required. Their good machinability allows versatility in component fabrication.

Quality Assurance and Certification

Each batch of ASTM A182 Gr F9 Alloy Steel Bars is subjected to rigorous ultrasonic, hardness, chemical, and mechanical testing. Test certificates are provided with every order, verifying compliance with all relevant standards and customer specifications. The bars are packed according to standard export practices, ensuring safe delivery and integrity upon arrival.

FAQs of ASTM A182 Gr F9 Alloy Steel Bars:

Q: How are ASTM A182 Gr F9 Alloy Steel Bars manufactured?

A: These alloy steel bars are produced through either hot rolling or forging, followed by heat treatment. This process enhances their strength, toughness, and overall mechanical properties, making them suitable for demanding industrial applications.Q: What testing and certifications are provided with these steel bars?

A: Each bar undergoes ultrasonic inspection, hardness measurement, chemical analysis, and mechanical testing. Test certificates for these evaluations accompany every shipment, ensuring transparency and quality compliance.Q: When is ASTM A182 Gr F9 Alloy Steel Bar the preferred material?

A: These bars are ideal when high strength, excellent heat resistance, and good corrosion resistance are essentialsuch as in the manufacturing of flanges, valves, and other components for petrochemical, power generation, and high-temperature services.Q: Where are these alloy steel bars commonly used?

A: ASTM A182 Gr F9 Alloy Steel Bars are widely used in industrial, petrochemical, oil & gas, engineering, and power generation sectors, especially for parts operating under elevated temperatures and pressures.Q: What are the benefits of using ASTM A182 Gr F9 Alloy Steel Bars?

A: Key benefits include strong mechanical properties, high heat and corrosion resistance, good machinability, and availability in customizable dimensions and finishes, making them adaptable to specific project needs.Q: How is the product packaged and delivered?

A: Bars are packed using standard export methods, either bundled or loose depending on order specification, ensuring protection during transit. Lead times and minimum order quantities are negotiable based on contract and required quantities.Q: What dimensions and finishes are available for these steel bars?

A: They are supplied in diameters ranging from 6mm to 350mm, with lengths from 1 to 6 meters or as required. Finish options include bright, black, polished, rough turned, or peeled, with custom dimensions available upon request.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Alloy Steel Bar Category

ASTM A182 Gr F91 Alloy Steel Bars

Grade : F91

Steel Type : Alloy Steel

Hardness : Maximum 250 HB

Surface : Bright, Black, Polished

Heat Resistance : Yes

ASTM A182 Gr F22 Alloy Steel Bars

Grade : Gr F22

Steel Type : Alloy Steel

Hardness : 217 HB max (annealed)

Surface : Bright, Black, Polished, Peeled, Turned, Ground, Rough Machined

Heat Resistance : Yes

AISI 4130 Gr F91 Alloy Steel Bars

Grade : AISI 4130 Gr F91

Steel Type : Alloy Steel

Hardness : 200241 HBW

Surface : Polished, Bright, Black, Peeled, Turned

Heat Resistance : Yes

ASTM A182 Gr F5 Alloy Steel Bars

Grade : ASTM A182 Gr F5

Steel Type : Alloy Steel

Hardness : 183235 HB (Brinell Hardness)

Surface : Bright, Black, Polished

Heat Resistance : Yes

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese