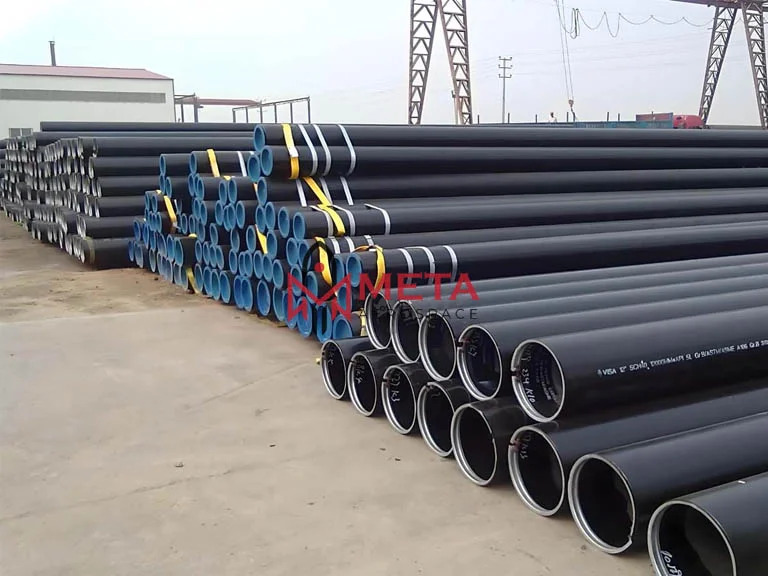

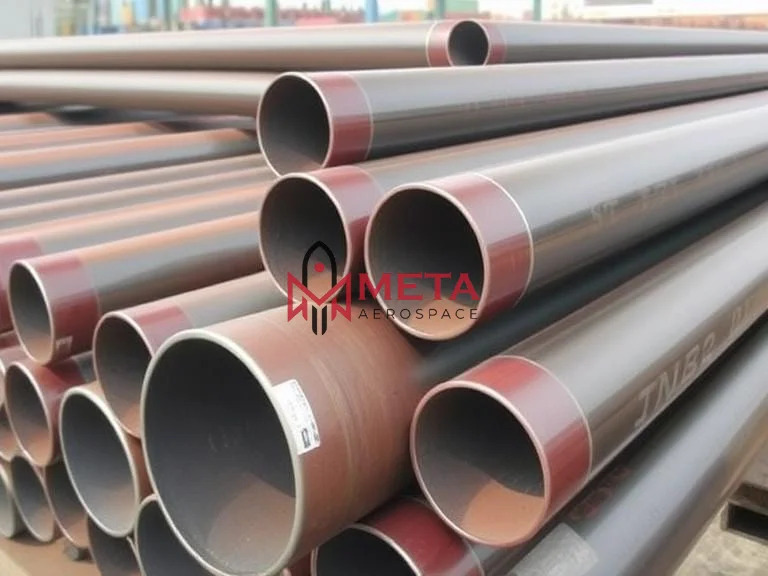

Carbon ASTM A671 CC60 Pipes

Carbon ASTM A671 CC60 Pipes Specification

- Material Grade

- ASTM A671

- Usage

- Industrial

- Material

- Steel

- Section Shape

- Round

- Standard

- ASTM

- Technique

- Hot Rolled

- Surface Treatment

- Galvanized

- Length

- 3 Meter (m)

- Warranty

- 1 Year

Carbon ASTM A671 CC60 Pipes Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1 Kilograms Per Week

- Delivery Time

- 1-2 Week

About Carbon ASTM A671 CC60 Pipes

What Are Specification Carbon ASTM A671 CC60 Pipes?

| Standard Specification | ASTM A671 CC60 |

|---|---|

| Codes and Standards | ANSI, API, ASME, ASTM, SAE, AGA, BS, AWWA, ISO, DIN |

| Standard Size | 1/2 Inch NB to 36 Inch NB |

| Wall Thickness | 3 To 12mm |

| Pipe schedules | Schedule 5, Schedule10, Schedule 40, Schedule 80, Schedule 80S, Schedule 160, Schedule XXS, Schedule XS |

| Producing techniques | EFW / ERW / Welded / Fabricated |

| Available Shapes | Round, Square, Half Round, Rectangular or Custom shape |

| Length | 3 to 18 Meters |

| Pipe End | Beveled End, Plain End, Treaded |

Chemical Composition Of Carbon ASTM A671 CC60 Pipes?

| Specification | Steel grade | Chemical composition | Remarks | |||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ti | |||

| Pipes for pressure service ASTM A671, A672 | -/A45 | -/0.17 | - | 0.98 | 0.035 | 0.035 | - | A671/ A672 |

-/A50 | -/0.22 | - | ||||||

CA55/A55 | 0.28 | - | ||||||

-/B55 | -/0.20 | 0.13 ~0.45 | ||||||

CB60/B60 | 0.24 | |||||||

CB65/B65 | 0.28 | |||||||

CB70/C70 | 0.31 | 1.30 | ||||||

-/C55 | -/0.18 | 0.55 ~0.98 | ||||||

CC60/C60 | 0.21 | |||||||

CC65/C65 | 0.24 | 0.79 ~1.30 | ||||||

CC70/C70 | 0.27 | |||||||

Mechanical Properties Of Carbon ASTM A671 CC60 Pipes?

| Products | Steel Grade | BASE METAL MECHANICAL COMPOSITION | Welding point tensile strength (N/mm2) | Remarks | |||

|---|---|---|---|---|---|---|---|

| Yield point (N/mm2) | Tensile Stregth (N/mm2) | Test Pieces | Elongation (%) | ||||

Pipes for pressure service ASTM A671, A672 | -/A45 | -/165 | -/310~450 | - | -/30 | -/310~450 | A671/ A672 |

-/A50 | -/185 | -/345~485 | -/28 | -/345~485 | |||

CA55/A55 | 205 | 380~515 | 27 | 380~515 | |||

-/B55 | -/205 | -/380~515 | -/27 | -/380~515 | |||

CB60/B60 | 220 | 415~550 | 25 | 415~550 | |||

CB65/B65 | 240 | 450~585 | 23 | 450~585 | |||

CB70/B70 | 260 | 485~620 | 21 | 485~620 | |||

-/C55 | -/205 | -/380~515 | -/27 | -/380~515 | |||

CC60/C60 | 220 | 415~550 | 25 | 415~550 | |||

CC65/C65 | 240 | 450~585 | 23 | 450~585 | |||

CC70/C70 | 260 | 485~620 | 21 | 485~620 | |||

Premium Quality and Durability

ASTM A671 CC60 pipes provide robust performance in challenging industrial environments. Their galvanized coating protects the steel from corrosion, extending the service life and reducing maintenance costs compared to non-coated alternatives. Each pipe is precision-made, ensuring consistent standards and reliability for various industrial tasks.

Versatile Industrial Applications

These carbon steel pipes are ideally suited for power plants, chemical processing, oil and gas transmission, and other heavy-duty sectors. With a standardized 3-meter length and round shape, installation and handling are made efficient. Their high-strength construction supports pressurized systems and demanding transport processes.

FAQs of Carbon ASTM A671 CC60 Pipes:

Q: How are Carbon ASTM A671 CC60 Pipes manufactured?

A: These pipes are produced using the hot rolled technique, which involves heating steel to high temperatures and shaping it into a round section. The surface is then galvanized, providing additional durability against corrosion and environmental wear.Q: What is the primary usage of ASTM A671 CC60 pipes in industrial settings?

A: ASTM A671 CC60 pipes are predominantly used to transport fluids and gases in power plants, oil & gas industries, and chemical processing facilities due to their strength, reliability, and corrosion resistance.Q: Where can these pipes be installed and utilized?

A: These pipes are suitable for installation in various industrial areas including refineries, petrochemical plants, thermal power stations, and other facilities requiring secure fluid or gas transmission.Q: When should I consider using galvanized ASTM A671 CC60 pipes over non-galvanized alternatives?

A: Galvanized pipes should be chosen when enhanced corrosion resistance is required, particularly in environments exposed to moisture, chemicals, or outdoor conditions where pipe longevity is critical.Q: What is involved in the surface treatment process for these pipes?

A: After forming the steel pipes through hot rolling, they undergo a galvanization process, which coats the surface with a protective layer of zinc, helping to prevent rust and degradation over time.Q: How does a 1-year warranty benefit industrial buyers?

A: The 1-year warranty provides assurance against manufacturing defects, ensuring buyers are protected and receive dependable quality, which is essential for business continuity in industrial operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carbon Steel Pipe Category

Carbon ASTM A252 Pipes

Material : Carbon Steel

Technique : Other, ERW / Seamless / Welded

Section Shape : Round

Surface Treatment : Other, Oiled, Painted, 3LPE Coating

Carbon ASTM A672 C70 Pipes

Minimum Order Quantity : 50 Kilograms

Material : Steel

Technique : Hot Rolled

Section Shape : Round

Surface Treatment : Galvanized

Carbon ASTM A333 Grade 3 Pipes

Minimum Order Quantity : 50 Kilograms

Material : Steel

Technique : Hot Rolled

Section Shape : Round

Surface Treatment : Galvanized

Material Grade : ASTM A333

Carbon ASTM A671 Pipes

Minimum Order Quantity : 50 Kilograms

Material : Steel

Technique : Hot Rolled

Section Shape : Round

Surface Treatment : Galvanized

Material Grade : ASTM A671

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese