Call: 07313726336

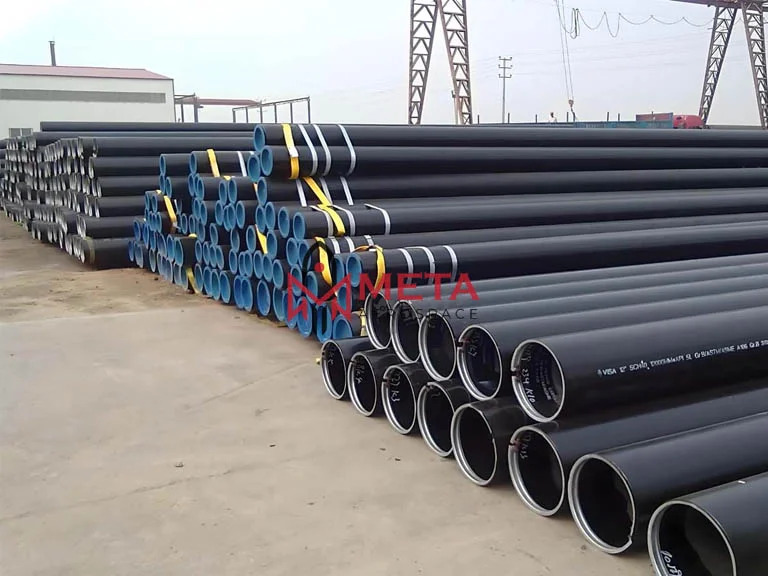

Carbon ASTM A672 C70 Pipes

MOQ : 50 Kilograms

Carbon ASTM A672 C70 Pipes Specification

- Surface Finish

- Polished

- Usage

- Industrial

- Features

- Durable

- Material

- Steel

- Section Shape

- Round

- Technique

- Hot Rolled

- Surface Treatment

- Galvanized

- Size

- 1/2 NB to 36 NB

- Length

- 3 Meter (m)

- Warranty

- 1 Year

Carbon ASTM A672 C70 Pipes Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1 Kilograms Per Week

- Delivery Time

- 1-2 Week

About Carbon ASTM A672 C70 Pipes

What Are Specification Carbon ASTM A672 C70 Pipes?

| Type | ASTM A672 Gr. B60/ B65/ B70/ C60/ C65/ C70 LSAW / SAW / EFW Pipe | |

|---|---|---|

| Executive Standard | API SPEC 5L,GB/T 9711.1,GB/T 9711.2,GB/T 9711.3,SY/T5037 | |

| ASTM A671 | Standard Specification for Electric-Fusion-Welded Steel Pipe for Atmospheric and Lower Temperatures | |

| ASTM A672 | Standard Specification for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures | |

| Class Designation | Class 10, 11, 12, 13, 20, 21, 22, 23, 30, 31, 32, 33, 34, 40, 41, 42, 43, 50, 51, 52, 53, 60, 61, 62, 63, 70, 71, 72, 73. | |

| Size | Outer Diameter | 12-64 inch |

| Wall Thickness | 2-60mm SCH10, SCH20, SCH30, STD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160, XXS | |

| Length | Single random length/Double random length 5m-14m,5.8m,6m,10m-12m,12m or as customer's actual request | |

| Ends | Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded and coupling,etc | |

| Surface Treatment | Bare,Painting black,varnished,galvanized,anti-corrosion PE PP/EP/FBE coating | |

| Technical Methods | Hot-rolled/Cold-drawn/Hot-expanded | |

| Testing Methods | Eddy current testing, Hydrostatic testing or Ultrasonic examination, NDT and also with chemical and physical property inspection | |

| Packaging | Small pipes in bundles with strong steel strips,large pieces in loose; Covered with plastic woven bags; Suitable for lifting operation; Loaded in 40ft or 20ft container or in bulk Also according to customer's requests | |

| Application | Conveying oil, gas and water | |

| MOQ | 1 ton | |

| Production Capacity | 5000 T/M | |

| Delivery Time | Within 2 Weeks | |

Chemical Composition Of Carbon ASTM A672 C70 Pipes?

| Specification | Steel grade | Chemical composition | Remarks | |||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ti | |||

| Pipes for pressure service ASTM A671, A672 | -/A45 | -/0.17 | - | 0.98 | 0.035 | 0.035 | - | A671/ A672 |

| -/A50 | -/0.22 | - | ||||||

| CA55/A55 | 0.28 | - | ||||||

| -/B55 | -/0.20 | 0.13 ~0.45 | ||||||

| CB60/B60 | 0.24 | |||||||

| CB65/B65 | 0.28 | |||||||

| CB70/C70 | 0.31 | 1.30 | ||||||

| -/C55 | -/0.18 | 0.55 ~0.98 | ||||||

| CC60/C60 | 0.21 | |||||||

| CC65/C65 | 0.24 | 0.79 ~1.30 | ||||||

| CC70/C70 | 0.27 | |||||||

Mechanical Properties Of Carbon ASTM A672 C70 Pipes?

| Products | Steel Grade | BASE METAL MECHANICAL COMPOSITION | Welding point tensile strength (N/mm2) | Remarks | |||

|---|---|---|---|---|---|---|---|

| Yield point (N/mm2) | Tensile Stregth (N/mm2) | Test Pieces | Elongation (%) | ||||

| Pipes for pressure service ASTM A671, A672 | -/A45 | -/165 | -/310~450 | - | -/30 | -/310~450 | A671/ A672 |

| -/A50 | -/185 | -/345~485 | -/28 | -/345~485 | |||

| CA55/A55 | 205 | 380~515 | 27 | 380~515 | |||

| -/B55 | -/205 | -/380~515 | -/27 | -/380~515 | |||

| CB60/B60 | 220 | 415~550 | 25 | 415~550 | |||

| CB65/B65 | 240 | 450~585 | 23 | 450~585 | |||

| CB70/B70 | 260 | 485~620 | 21 | 485~620 | |||

| -/C55 | -/205 | -/380~515 | -/27 | -/380~515 | |||

| CC60/C60 | 220 | 415~550 | 25 | 415~550 | |||

| CC65/C65 | 240 | 450~585 | 23 | 450~585 | |||

| CC70/C70 | 260 | 485~620 | 21 | 485~620 | |||

Versatile Industrial Pipe Solution

ASTM A672 C70 carbon steel pipes are developed to meet demanding industrial requirements. Their robust construction, galvanized surface, and standardized sizing from 1/2 NB to 36 NB make them suitable for a wide range of pressure-bearing and fluid-transport applications.

Superior Durability and Finish

Each pipe undergoes hot rolling and is meticulously polished before receiving a protective galvanized treatment. This process not only enhances the pipes appearance but also improves its corrosion resistance, ensuring lasting performance in challenging environments.

Trusted Supply Chain

As a leading exporter, manufacturer, supplier, and trader in India, we ensure seamless access to high-quality ASTM A672 C70 pipes. Our distribution network is equipped to deliver tailored solutions for industrial projects both locally and globally.

FAQs of Carbon ASTM A672 C70 Pipes:

Q: How are Carbon ASTM A672 C70 Pipes manufactured?

A: These pipes are produced using a hot-rolled method, which imparts strength and consistent wall thickness. After forming, they undergo a galvanizing process to provide a corrosion-resistant surface, followed by polishing for an enhanced finish.Q: What industries commonly use ASTM A672 C70 pipes?

A: The pipes are primarily used in sectors such as oil and gas, power generation, chemical processing, water transmission, and other industrial applications requiring durable and high-strength piping.Q: When should I choose galvanized ASTM A672 C70 pipes over non-galvanized alternatives?

A: Galvanized pipes are recommended when the operating environment exposes steel to moisture or chemicals, as the zinc coating offers superior protection against rust and corrosion compared to non-galvanized options.Q: Where can I source ASTM A672 C70 pipes in India?

A: You can procure these pipes from established manufacturers, exporters, suppliers, and traders across India, specializing in industrial-grade steel products. Our company provides a wide range of sizes and finishes to accommodate diverse project requirements.Q: What is the process behind the galvanized surface treatment of these pipes?

A: After hot rolling, the pipes undergo galvanizing, where they are coated with a layer of zinc to prevent corrosion, followed by polishing for a smooth and appealing finish.Q: How can these pipes be utilized in industrial projects?

A: Their durability, strength, and corrosion resistance make them suitable for transporting fluids and gases, as well as structural applications within various industrial settings.Q: What are the main benefits of selecting ASTM A672 C70 pipes with a 1-year warranty?

A: Choosing these pipes ensures reliable performance and product support. The 1-year warranty offers peace of mind regarding material defects or manufacturing issues, supporting uninterrupted industrial operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Carbon Steel Pipe Category

Carbon ASTM 106 Grade B Pipes

Technique : Hot Rolled

Material : Carbon Steel

Length : 6 meter, 12 meter, and custom lengths

Section Shape : Round

Carbon ASTM A671 CC60 Pipes

Minimum Order Quantity : 50 Kilograms

Technique : Hot Rolled

Material : Steel

Length : 3 Meter (m)

Material Grade : ASTM A671

Section Shape : Round

Carbon ASTM A671 CC70 Pipes

Minimum Order Quantity : 50 Kilograms

Technique : Hot Rolled

Material : Steel

Length : 3 Meter (m)

Material Grade : ASTM A671

Section Shape : Round

ASTM A106 Grade C Pipe

Minimum Order Quantity : 50 Kilograms

Technique : Hot Rolled

Material : Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese