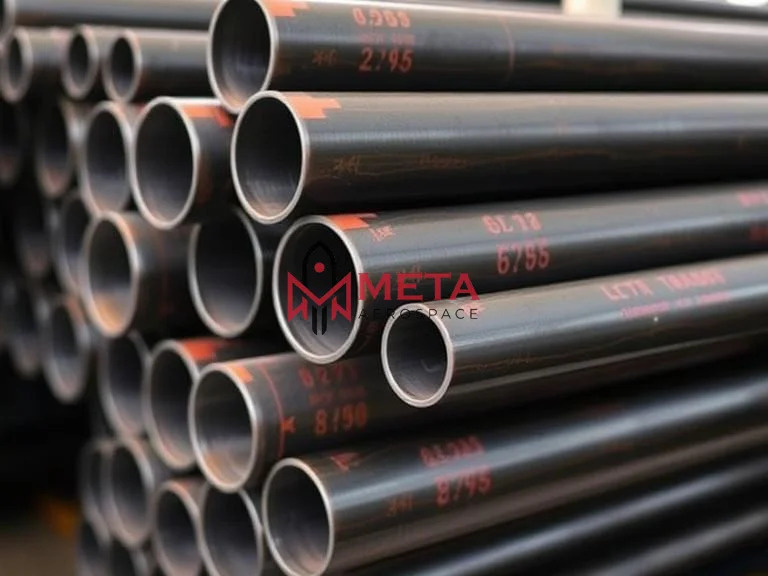

EN 10294-1 Grade E235 Pipes

EN 10294-1 Grade E235 Pipes Specification

- Temperature Range

- -20C to 350C

- Bend Radius

- As per standard

- Coating Type

- Anti-corrosion Coated

- Connection Type

- Butt Weld / Socket Weld

- Tensile Strength

- 340 480 MPa

- Diameter

- 21.3 mm to 457 mm

- Yield Strength

- >=235 MPa

- Flexibility

- Rigid

- Tolerance

- +/- 1%

- Product Type

- Seamless Pipes

- Material

- Carbon Steel

- Connection

- Plain Ends / Beveled Ends

- Shape

- Round

- Standard

- EN 10294-1

- Surface Treatment

- Oiled, Phosphated or as required

- Outer Diameter

- 21.3 mm to 457 mm

- Section Shape

- Hollow

- Length

- 3 Meter, 6 Meter, 12 Meter or Custom

- Thickness

- 1.5 mm to 20 mm

- Color

- Black

- Usage

- Engineering, Mechanical, Automotive

- Rated Pressure

- As per standards

- Application

- Machining, Manufacturing of Hollow Bars, Construction

- Material Grade

- E235

- End Protection

- Plastic Caps on Both Ends

- MOQ

- Negotiable as per order size

- Packing

- Bundled with Steel Strips

- Hardness

- 180 HB

- Manufacturing Process

- Seamless Hot Finished Pipes

- Inspection

- 100% Hydrostatic Tested

- Surface Finish

- Cold Finished or Hot Finished

- Test Certificates

- EN 10204/3.1 or 3.2 as Required

About EN 10294-1 Grade E235 Pipes

What Are Specification EN 10294-1 Grade E235 Pipes?

| EN 10294-1 Grade E275 Carbon Steel Square bar size | 4 to 100mm |

|---|---|

| EN 10294-1 Grade E275 Carbon Steel Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| EN 10294-1 Gr E275 Hex Bar size | 2-100mm A/F |

| EN 10294-1 Gr E275 Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| EN 10294-1 Grade E275 Carbon Steel Rectangles Size | 33 x 30mm to 295 x 1066mm |

| EN 10294-1 Gr E275 Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Carbon EN 10294-1 Grade E275 Steel Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| EN 10294-1 Grade E275 Carbon Steel Section | 3.0 to 12.0mm thickness |

| EN 10294-1 Gr E275 Round bar size | Diameter: 3-~800mm |

| Steel Grade E275 Billet Size | 1/2" to 495mm Diameter |

| Carbon Steel EN 10294-1 E275 Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| EN 10294-1 Grade E275 Carbon Steel Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| EN 10294-1 Gr E275 Technique | Steel EN 10294-1 Grade E275 Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Carbon Steel EN 10294-1 Grade E275 Condition | Hardened & tempered, annealed |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Form | Grade 38Mn6 Carbon Steel Round, Rod, T-Bar, Nickel Alloy Channel Bar, Precision Ground Bar, Nickel Alloy Flat Bar, Nickel Alloy Square Bar, Nickel Alloy Blocks, Nickel Alloy Round Rod, Nickel Alloy Rings, Nickel Alloy Hollow, Nickel Alloy Triangle, Rectangle, Hex (A/F), Nickel Alloy Threaded, Half Round Bar, Profiles, Nickel Alloy Billet, Nickel Alloy Ingot, I/H Bar, Forging etc. |

| Processing | Bar cutting to 650mm |

| Our EN 10294-1 Grade E275 Round bar conforms to NACE MR0175/ISO 15156 | |

Equivalent material Of EN 10294-1 Grade E235 Pipes?

| DIN | EN | BS | NFA | ASTM | ASME |

|---|---|---|---|---|---|

| EN 10294-1 Grade E275 |

Chemical Composition Of EN 10294-1 Grade E235 Pipes?

| Carbon | Silicon | Manganese | Phosphorous | Sulphur | Molybdenum | Nickel | Chromium | Copper | Others |

|---|---|---|---|---|---|---|---|---|---|

| max 0.21 | max 0.35 | max 1.40 | 0.045 | 0.045 |

Mechanical Properties Of EN 10294-1 Grade E235 Pipes?

| Yield Strength | Tensile Strength | Elongation A5 min | |||

|---|---|---|---|---|---|

| MPa min | ksi min | MPa min | MPa min | ksi min | Percentage |

| 410 | 22 | ||||

Manufacturing Excellence and Quality Assurance

EN 10294-1 Grade E235 pipes are produced using seamless hot finishing processes, ensuring remarkable structural integrity. Each pipe undergoes 100% hydrostatic testing and strict dimensional checks (tolerance: +/- 1%). Test certificates (EN 10204/3.1 or 3.2) are provided as required, highlighting compliance with international standards and guaranteeing traceable quality.

Versatile Applications Across Industries

With their robust mechanical properties, these pipes are ideal for machining, manufacturing hollow bars, construction projects, and diverse engineering uses. Their wide diameter and thickness range allows tailoring to project-specific needs, while options for length and connection ensure flexibility in installation and operation within various industries.

Protective Coating and End Finishing

To maximize the lifespan and safety of piping solutions, EN 10294-1 Grade E235 pipes are supplied with anti-corrosion coatings and plastic caps on both ends. Surface treatment options include oiled or phosphated finishes, meeting specific project or environmental requirements and maintaining operational reliability even under demanding conditions.

FAQs of EN 10294-1 Grade E235 Pipes:

Q: How are EN 10294-1 Grade E235 pipes manufactured?

A: These pipes are produced through a seamless hot finished manufacturing process, which creates robust, uniform tubes. The result is improved strength and reliability, making the pipes suitable for demanding engineering and mechanical uses.Q: What testing and certification are performed on these pipes?

A: Each pipe undergoes 100% hydrostatic testing to ensure leak-proof performance. Test certificates per EN 10204/3.1 or 3.2 are issued as required, assuring compliance with international standards and ensuring quality and traceability.Q: Where can EN 10294-1 Grade E235 pipes be used?

A: They are suitable for engineering, mechanical, automotive, machining, hollow bar manufacturing, and construction applications due to their strength and dimensional versatility.Q: What surface finish and protective measures are applied to these pipes?

A: The pipes can feature cold or hot finished surfaces, and are supplied with anti-corrosion coatings. Additionally, they are protected with plastic caps on both ends and bundled with steel strips for safe handling and transport.Q: What are the dimensions and customization options available?

A: Outer diameters range from 21.3 mm to 457 mm and thicknesses from 1.5 mm to 20 mm. Standard lengths include 3, 6, or 12 meters, with custom lengths available upon request. End types and surface treatments can also be tailored to specific project needs.Q: What is the minimum order quantity (MOQ) for these pipes?

A: The MOQ is negotiable and can be adjusted based on order size, which enables flexible volume procurement for both large and small requirements.Q: What are the key benefits of choosing EN 10294-1 Grade E235 pipes?

A: Customers gain high tensile and yield strength, precise tolerances, verified quality through certificates, robust corrosion protection, and flexible sizingall designed for durability and optimal performance across a wide range of industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EN Standards Pipe Category

EN 10210 S355J2H Pipes

Diameter : 21.3 mm 508 mm

Usage : Structural, Construction, Machinery, General Engineering

Tensile Strength : 510 MPa

Surface Treatment : Other, Black Painted, Bare, Oil Coated, Galvanized

Rated Pressure : As per design/requirement

Thickness : 2 mm 40 mm

EN 10219 S355JOH Pipes

Diameter : Up to 508 mm

Usage : Construction, Structural, Engineering Applications

Tensile Strength : 470 630 MPa

Surface Treatment : Other, Black Painted / Pregalvanized / Bare

Rated Pressure : According to thickness and diameter, typically PN16PN64

Thickness : 2.0 mm to 12.5 mm

EN 10216-1 P235TR2 Pipes

Diameter : 10.2 mm 711 mm

Usage : Fluid Transmission, Boiler, Mechanical, Gas, Oil

Tensile Strength : 360 500 MPa

Surface Treatment : Other, Black Painted, Oiled or Bare

Rated Pressure : According to service, pressure rating on request

Thickness : 3.2 mm to 30 mm

EN 10219 S235JRH Pipes

Diameter : 21.3 mm to 508 mm

Usage : Structural, Construction, Engineering

Tensile Strength : 360510 MPa

Surface Treatment : Other, Black Painted, Galvanized, Bare

Rated Pressure : Custom/On Request

Thickness : 1.5 mm to 16 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese