EN 10294-1 Grade E355+N Pipes

EN 10294-1 Grade E355+N Pipes Specification

- Temperature Range

- -20C to +450C

- Yield Strength

- 470 MPa min

- Tolerance

- EN 10294-1 standard tolerance

- Connection Type

- Plain / Bevel End

- Coating Type

- Antirust Oil / Black Paint

- Bend Radius

- Not specified (typically not applicable for rigid pipes)

- Tensile Strength

- 540 700 MPa

- Thread Type

- Not threaded (Plain End)

- Diameter

- 32 mm 355.6 mm

- Flexibility

- Rigid

- Product Type

- Seamless Hollow Bar Pipe

- Material

- Carbon Steel

- Connection

- Plain End, Beveled End

- Shape

- Round

- Standard

- EN 10294-1

- Surface Treatment

- Black Painted, Oiled

- Outer Diameter

- 32 mm 355.6 mm

- Section Shape

- Circular

- Length

- 5 m 12 m (or Customized)

- Thickness

- 2.5 mm 40 mm (customizable)

- Color

- Black

- Usage

- Hydraulic, Pneumatic, Machining, General Engineering

- Rated Pressure

- Up to 350 bar (dependent on size/thickness)

- Material Grade

- E355+N

- Application

- Cylinder Tubes, Mechanical Engineering, Precision Components, Automotive

- Elongation

- 20% min

- Heat Treatment

- Normalized (N)

- Manufacturing Process

- Seamless, Normalized

- End Finish

- Square Cut, Deburred

- Density

- ~7.85 g/cm

- Magnetic Properties

- Magnetic (carbon steel)

- Impact Test

- 27J at -20C (as per standard)

- Packaging

- Plastic Caps on Both Ends, Bundled, Wooden Cases

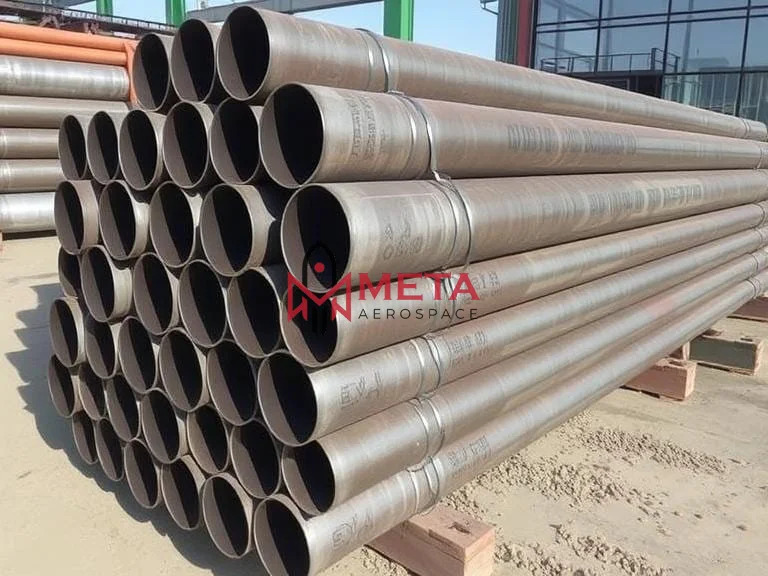

About EN 10294-1 Grade E355+N Pipes

What Are Specification EN 10294-1 Grade E355+N Pipes?

| EN 10294-1 Grade E355+N Carbon Steel Square bar size | 4 to 100mm |

|---|---|

| EN 10294-1 Grade E355+N Carbon Steel Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Carbon Steel EN 10294-1 E355+N Hex Bar size | 2-100mm A/F |

| Carbon Steel EN 10294-1 E355+N Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| EN 10294-1 Grade E355+N Carbon Steel Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Carbon Steel EN 10294-1 E355+N Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| EN 10294-1 Grade E355+N Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| EN 10294-1 Grade E355+N Carbon Steel Section | 3.0 to 12.0mm thickness |

| Carbon Steel EN 10294-1 E355+N Round bar size | Diameter: 3-~800mm |

| EN 10294-1 Gr E355+N Billet Size | 1/2" to 495mm Diameter |

| CS EN 10294-1 Grade E355+N Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| EN 10294-1 Grade E355+N Carbon Steel Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Carbon Steel EN 10294-1 E355+N Technique | EN 10294-1 Gr E355+N Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Carbon Steel EN 10294-1 Grade E355+N Condition | Hardened & tempered, annealed |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Form | Grade 38Mn6 Carbon Steel Round, Rod, T-Bar, Nickel Alloy Channel Bar, Precision Ground Bar, Nickel Alloy Flat Bar, Nickel Alloy Square Bar, Nickel Alloy Blocks, Nickel Alloy Round Rod, Nickel Alloy Rings, Nickel Alloy Hollow, Nickel Alloy Triangle, Rectangle, Hex (A/F), Nickel Alloy Threaded, Half Round Bar, Profiles, Nickel Alloy Billet, Nickel Alloy Ingot, I/H Bar, Forging etc. |

| Processing | Bar cutting to 650mm |

| Our Carbon EN 10294-1 Grade E355+N Steel Round bar conforms to NACE MR0175/ISO 15156 | |

Equivalent material Of EN 10294-1 Grade E355+N Pipes?

| DIN | EN | BS | NFA | ASTM | ASME |

|---|---|---|---|---|---|

| EN 10294-1 Grade E355+N |

Chemical Composition Of EN 10294-1 Grade E355+N Pipes?

| Carbon | Silicon | Manganese | Phosphorous | Sulphur | Molybdenum | Nickel | Chromium | Copper | Others |

|---|---|---|---|---|---|---|---|---|---|

| max 0.22 | max 0.50 | max 1.50 | 0.045 | 0.05 | max 0.08 | max 0.40 | max 0.30 | max 0.30 | V max 0.10 |

Mechanical Properties Of EN 10294-1 Grade E355+N Pipes?

| Yield Strength | Tensile Strength | Elongation A5 min | |||

|---|---|---|---|---|---|

| MPa min | ksi min | MPa min | MPa min | ksi min | Percentage |

| 490 | 20 | ||||

Reliable Seamless Construction

Manufactured through a seamless process and normalized heat treatment, EN 10294-1 Grade E355+N pipes offer superior strength, uniformity, and durability. These properties make them ideal for high-pressure and precision applications in industries such as hydraulic systems, mechanical engineering, and automotive manufacturing.

Versatile Dimensions & Application

Available in a range of thicknesses (2.5 mm to 40 mm) and diameters (32 mm to 355.6 mm), these round pipes can be customized in length (512 m or as needed) to fit specific engineering needs. Their magnetic properties and robust finish ensure reliable use in hydraulic cylinders, pneumatic systems, and precision components.

Strict Quality & Safety Compliance

Each pipe adheres to EN 10294-1 tolerance standards, ensuring consistency and safety. All pipes undergo impact testing (27J at -20C), have square cut deburred ends, and are packed with careplastic caps, bundled and encased in woodguaranteeing safe transport and adherence to international requirements.

FAQs of EN 10294-1 Grade E355+N Pipes:

Q: How are EN 10294-1 Grade E355+N pipes manufactured and heat treated?

A: These pipes are manufactured using a seamless method, which eliminates welds for increased integrity. They undergo normalized heat treatment, resulting in a uniform grain structure and improved mechanical properties, such as higher yield and tensile strengths.Q: What applications are suitable for EN 10294-1 Grade E355+N pipes?

A: They are commonly used in hydraulic and pneumatic cylinders, precision machining, mechanical engineering, and automotive components, thanks to their rigidity, strength, and customizable dimensions.Q: When is impact testing performed on these pipes, and at what standard?

A: Impact testing is conducted as per the EN 10294-1 standard, specifically at 27 Joules at -20C, to ensure the pipes performance and safety in low-temperature or high-stress environments.Q: Where are these pipes typically supplied and exported from?

A: EN 10294-1 Grade E355+N pipes are exported and supplied by manufacturers, exporters, suppliers, and traders based in India, serving both domestic and international markets.Q: What finishing and packaging processes are used for these pipes?

A: Each pipe receives square cut ends that are deburred for safety, optionally painted in black or coated with antirust oil, and ends protected with plastic caps. They are bundled and securely packed in wooden cases for transport.Q: How does the pipes material grade and surface treatment benefit performance?

A: The E355+N grade offers high strength and reliable performance, especially when normalized. Surface treatments such as black painting or antirust oil prevent corrosion, extending service life in demanding conditions.Q: What are the main benefits of using these pipes in hydraulic and pneumatic systems?

A: Their seamless and normalized construction ensures high pressure resistance (up to 350 bar), rigidity, and precise roundness, which are crucial for efficient hydraulic and pneumatic operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EN Standards Pipe Category

EN 10219 S275JOH Pipes

Material : Other , Nonalloy structural steel

Usage : Structural Engineering, Construction

Standard : Other, EN 10219

Surface Treatment : Other, Black Painted or Bare

Connection : Other, Welded

Material Grade : S275JOH

EN 10025-5 S355J0W Pipes

Material : Other , Weathering steel

Usage : Structural, Engineering, Outdoor Constructions, Bridges, Architectural

Standard : Other, EN 100255

Surface Treatment : Other, Bare, Painted, Oil Coated, Anti Corrosive Coated

Connection : Other, Welded, Seamless, Threaded

Material Grade : S355J0W

EN 10294-1 Grade E315 Pipes

Material : Other , Alloy Steel

Usage : Machining, Mechanical Engineering

Standard : Other, EN 102941

Surface Treatment : Other, Black Painted / Bare / Oiled

Connection : Other, Plain/Beveled Ends

Material Grade : E315

EN 10210-1 Grade S355JOH Pipes

Material : Carbon Steel

Usage : Structural and Mechanical Applications

Standard : Other, EN 102101, EN 102191

Surface Treatment : Other, Black Painted, Galvanized, Bare

Connection : Other, Plain End, Beveled End, Threaded

Material Grade : S355JOH

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese