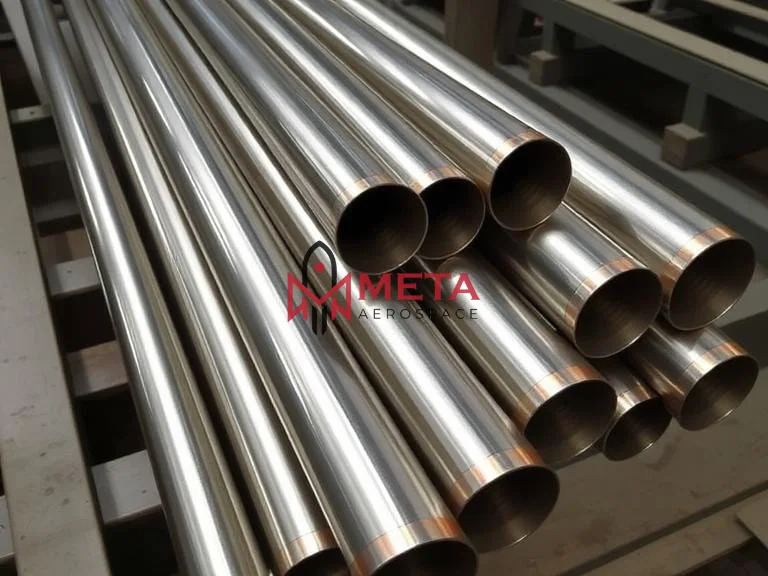

Inconel 718 Pipes

MOQ : 50 Kilograms

Inconel 718 Pipes Specification

- Connection

- Welding

- Shape

- Round

- Standard

- ASTM

- Surface Treatment

- Galvanized

- Color

- Sliver

- Warranty

- 1 Year

- Usage

- Industrial

- Material Grade

- Inconel 718

- Application

- Structure Pipe

Inconel 718 Pipes Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1 Kilograms Per Week

- Delivery Time

- 1-2 Week

About Inconel 718 Pipes

What Are Specification Inconel 718 Pipes?

| Specifications | ASTM B 167 ASME SB 167 / ASTM B 829 ASME SB 829 / ASTM B 517 ASME SB 517 |

|---|---|

| Dimensions | ASTM, ASME and API |

| Seamless 625 Pipe | 4 to 219mm W. T.: 0.5 to 20mm |

| Welded 625 Pipe | 5.0 mm 1219.2 mm |

| EFW 625 Pipe | 5.0 mm 1219.2 mm |

| Size | 15NB TO 150NB IN |

| Specialized in | Large Diameter Size |

| Schedule | SCH5, SCH10, SCH40, STD, SCH80, SCH160 |

| Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| Form | Round, Hydraulic Etc |

| Length | Single Random, Double Random & Cut Length. |

| End | Plain End, Beveled End, Treaded |

Equivalent material Of Inconel 718 Pipes?

| STANDARD | WNR Material Number | JIS | EN | BS | UNS | AFNOR | GOST |

|---|---|---|---|---|---|---|---|

| 625 | 2.4856 | NCF 625 | NiCr22Mo9Nb | NA 21 | N06625 | NC22DNB4M | 75 |

Chemical Composition Of Inconel 718 Pipes?

| Grade | C | Mn | Si | Fe | S | Cr2 | Al-Ti | Ni | |

|---|---|---|---|---|---|---|---|---|---|

| 625 | min. | 20.0 | 58.0 | ||||||

| max. | 0.10 | 0.50 | 0.50 | 5.0 | 0.015 | 23.0 | 0.40 | ||

Mechanical Properties Of Inconel 718 Pipes?

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Inconel 718 | 8.4 g/cm3 | 1350 C (2460 F) | Psi 1,35,000 , MPa 930 | Psi 75,000 , MPa 517 | 42.5 % |

Exceptional Performance in Industrial Environments

Inconel 718 Pipes are specially engineered for use in demanding industrial sectors due to their remarkable mechanical strength and corrosion resistance. The galvanized surface treatment provides an added layer of protection, ensuring a long service life even under harsh operational conditions.

Compliance with Global Quality Standards

Our Inconel 718 Pipes adhere strictly to ASTM standards, guaranteeing consistent quality and performance across diverse industrial projects. Whether used in structural frameworks or specialized machinery, these pipes meet rigorous international benchmarks for safety and reliability.

Versatile Applications and Easy Installation

With a round shape and welded connections, Inconel 718 Pipes are suited to various structural applications in sectors such as power, petrochemicals, and heavy engineering. Their user-friendly design ensures straightforward installation, minimizing project downtime.

FAQs of Inconel 718 Pipes:

Q: How are Inconel 718 Pipes manufactured and treated for durability?

A: Inconel 718 Pipes are produced using advanced processes that ensure high strength and quality. After forming the pipes to the required specifications, they undergo a galvanized surface treatment, which enhances their resistance to corrosion and increases longevity in industrial environments.Q: What is the primary application of Inconel 718 Pipes in industry?

A: These pipes are mainly utilized in structural and industrial applications, such as supporting frameworks, pressure systems, and piping where high strength and corrosion resistance are essential. Their robust composition makes them ideal for critical projects.Q: Where are Inconel 718 Pipes commonly supplied and exported from?

A: Inconel 718 Pipes are manufactured, supplied, and exported throughout India by reputable companies who also act as traders. Their reliable quality and adherence to international standards make them suitable for both domestic and global markets.Q: When should I consider using Inconel 718 Pipes over other alloy pipes?

A: You should choose Inconel 718 Pipes when your project requires exceptional resistance to heat, corrosion, and pressureespecially in challenging industrial settings that outpace the capabilities of most other alloy pipes.Q: What are the benefits of galvanized surface treatment on Inconel 718 Pipes?

A: Galvanized treatment provides a resilient, protective coating that safeguards the pipes surface against rust and corrosion, ensuring longer life and lower maintenance costs, particularly in corrosive or moist environments.Q: How does the welding connection benefit the installation process?

A: The welding connection ensures a secure and leak-proof join, streamlining assembly and improving the stability of structural or process piping systems. It allows for reliable integration into existing setups.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Inconel Pipe Category

Inconel 800800H800HT Pipes

Minimum Order Quantity : 50 Kilograms

Usage : Industrial

Warranty : 1 Year

Surface Treatment : Galvanized

Connection : Welding

Standard : ASTM

Inconel 600 Pipe

Minimum Order Quantity : 50 Kilograms

Usage : Industrial

Warranty : 1 Year

Surface Treatment : Galvanized

Connection : Welding

Standard : AISI

Inconel Round Pipe

Minimum Order Quantity : 50 Kilograms

Usage : Industrial

Warranty : 1 Year

Surface Treatment : Galvanized

Connection : Welding

Standard : AISI

Inconel 625 Pipe

Minimum Order Quantity : 50 Kilograms

Usage : Industrial

Warranty : 1 Year

Surface Treatment : Galvanized

Connection : Welding

Standard : AISI

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese