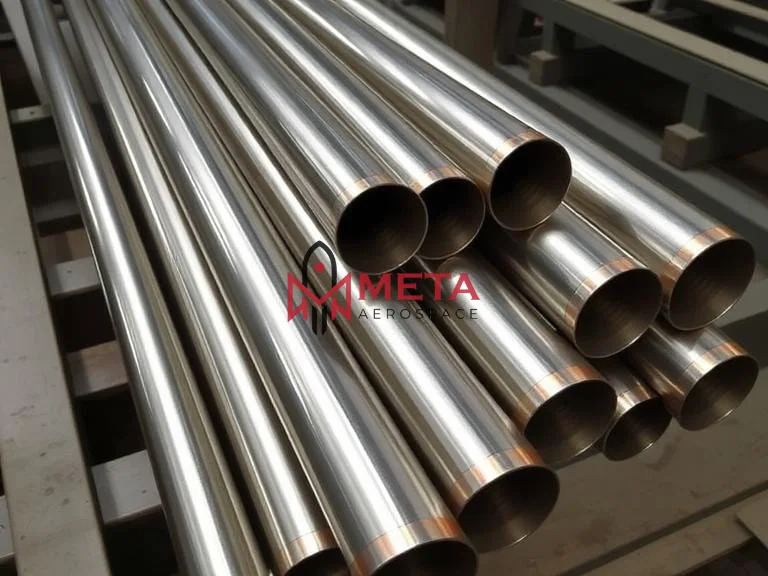

Inconel 800800H800HT Pipes

MOQ : 50 Kilograms

Inconel 800800H800HT Pipes Specification

- Usage

- Industrial

- Material

- Nickel

- Connection

- Welding

- Standard

- ASTM

- Surface Treatment

- Galvanized

- Color

- Sliver

- Warranty

- 1 Year

- Application

- Hydraulic Pipe

- Material Grade

- Inconel 800800H800HT Pipes

Inconel 800800H800HT Pipes Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1 Kilograms Per Week

- Delivery Time

- 1-2 Week

About Inconel 800800H800HT Pipes

What Are Specification Inconel 800/800H/800HT Pipes?

| Alloy 800 Pipe Specification | ASTM B 167 ASME SB 167 / ASTM B 829 ASME SB 829 / ASTM B 517 ASME SB 517 |

|---|---|

| Incoloy Alloy 800 Pipe Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| Our Presence | USA, Canada, Australia, UK, Malaysia, Poland, Iran, Italy, Singapore, UAE |

| Incoloy 800 Welded Pipe size | 5.0 mm 1219.2 mm |

| Alloy 800 EFW Pipe size | 5.0 mm 1219.2 mm |

| Specialized in | Large Diameter Alloy 800 Pipe |

| Incoloy 800 Pipe Form | Hollow, Square, Round, Rectangular , Straight Pipes, Hydraulic Etc. |

| Alloy 800 Pipe End | Plain End, Beveled End, Treaded. |

| Incoloy 800 Pipe Length | Single Random, Double Random & Cut Length. |

| Alloy 800 Seamless Pipe size | 4 to 219mm W. T.: 0.5 to 20mm |

| Marking | All Incoloy Alloy 800 Pipes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customers request.) |

| Manufacturers of Incoloy 800 Pipe |

|

| Incoloy 800 Pipe Schedule | SCH5, SCH10, SCH40, STD, SCH80, SCH160 |

| Material Test Certificates (MTC) | Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2 |

| Test |

|

| Origin | European, Japanese, Korean, US, Russian, Indian (Strictly No Chinese Material) |

| We can also cut, thread, and groove Incoloy 800 Pipes to meet your specifications. | |

Equivalent material Of Inconel 800/800H/800HT Pipes?

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

|---|---|---|---|---|---|---|---|---|

| Incoloy 800 Pipe | 1.4876 | N08800 | NCF 800 | NA 15 | 670 | Z8NC32-21 | X10NiCrAlTi32-20 | XH32T |

| Incoloy 800H Pipe | 1.4958 / 1.4876 | N08810 | NCF 800H | NA 15(H) | 670 | Z8NC33-21 | X5NiCrAlTi31-20 | XH32T |

| Incoloy 800HT Pipes | 1.4859 / 1.4876 | N08811 | NCF 800HT | NA 15(HT) | 670 | X8NiCrAlTi32-21 | XH32T |

Chemical Composition Of Inconel 800/800H/800HT Pipes?

| Grade | C | Mn | Si | Fe | S | Cr | Al-Ti | Ni | |

|---|---|---|---|---|---|---|---|---|---|

| Incoloy 800 Pipe | min. | 39.5 | 19.0 | 0.15 | 30.0 | ||||

| max. | 0.1 | 1.5 | 1.0 | 0.015 | 23.0 | 0.60 | 35.0 | ||

| Incoloy 800H Pipe | min. | 0.05 | 39.5 | 19.0 | 0.15 | 30.0 | |||

| max. | 0.1 | 1.5 | 1.0 | 0.015 | 23.0 | 0.60 | 35.0 | ||

| Incoloy 800HT Pipes | min. | 0.06 | 39.5 | 19.0 | 0.85/0.25 | 30.0 | |||

| max. | 0.1 | 1.5 | 1.0 | 0.015 | 23.0 | 1.20/0.60 | 35.0 | ||

Mechanical Properties Of Inconel 800/800H/800HT Pipes?

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 800-H-HT | Psi 75,000 , MPa 520 | Psi 30,000 , MPa 205 | 30 | ||

Outstanding Material Performance

Inconel 800/800H/800HT Pipes are crafted from a unique nickel-based alloy, providing remarkable resistance against oxidation and carburization, especially at elevated temperatures. Their galvanized finish enhances surface protection, making them ideal for challenging industrial environments where durability is critical.

Versatile Industrial Applications

These pipes are widely employed in high-stress applications such as hydraulic piping systems. Their robust construction ensures consistent flow and pressure resistance, making them a preferred choice in power plants, petrochemical refineries, and process industries requiring dependable pipework.

FAQs of Inconel 800800H800HT Pipes:

Q: How are Inconel 800/800H/800HT pipes typically used in industrial settings?

A: These pipes are mainly utilized in hydraulic piping systems and other critical industrial processes where high temperature and pressure resistance are essential. Their durability and corrosion resistance make them suitable for a variety of sectors, including chemical, petrochemical, and power generation.Q: What benefits do galvanized Inconel pipes offer over non-galvanized alternatives?

A: Galvanized Inconel pipes provide enhanced protection against surface corrosion, extending the service life of the pipes. This finish also contributes to a clean, silver appearance and minimizes maintenance needs in harsh environments.Q: When should one opt for Inconel 800/800H/800HT pipes over other materials?

A: These pipes are recommended when the application demands exceptional high-temperature stability, mechanical strength, and resistance to oxidation or carburization, such as in heat exchangers, furnace components, and hydraulic pipelines.Q: Where are these Inconel pipes manufactured and supplied from in India?

A: Top exporters, manufacturers, suppliers, and traders in India produce and distribute Inconel 800/800H/800HT pipes according to ASTM standards, ensuring consistent quality and reliable supply for industrial consumers.Q: What is the standard process for ensuring quality and performance in these pipes?

A: Manufacturers employ strict quality assurance protocols, conforming to ASTM standards. Regular testing covers mechanical strength, welding compatibility, surface treatment, and chemical composition to guarantee product integrity and application suitability.Q: How does the warranty enhance the reliability of these pipes?

A: A one-year warranty provides assurance of manufacturing quality. It protects buyers from defects or performance issues, thereby reinforcing confidence in long-term usage for industrial hydraulic and process applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Inconel Pipe Category

Inconel 718 Pipes

Minimum Order Quantity : 50 Kilograms

Standard : ASTM

Connection : Welding

Warranty : 1 Year

Usage : Industrial

Surface Treatment : Galvanized

Inconel 825 Pipes

Minimum Order Quantity : 50 Kilograms

Standard : ASTM

Connection : Welding

Warranty : 1 Year

Usage : Industrial

Surface Treatment : Galvanized

Inconel 601 Pipe

Minimum Order Quantity : 50 Kilograms

Standard : AISI

Connection : Welding

Warranty : 1 Year

Usage : Industrial

Surface Treatment : Galvanized

Inconel 600 Pipe

Minimum Order Quantity : 50 Kilograms

Standard : AISI

Connection : Welding

Warranty : 1 Year

Usage : Industrial

Surface Treatment : Galvanized

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese