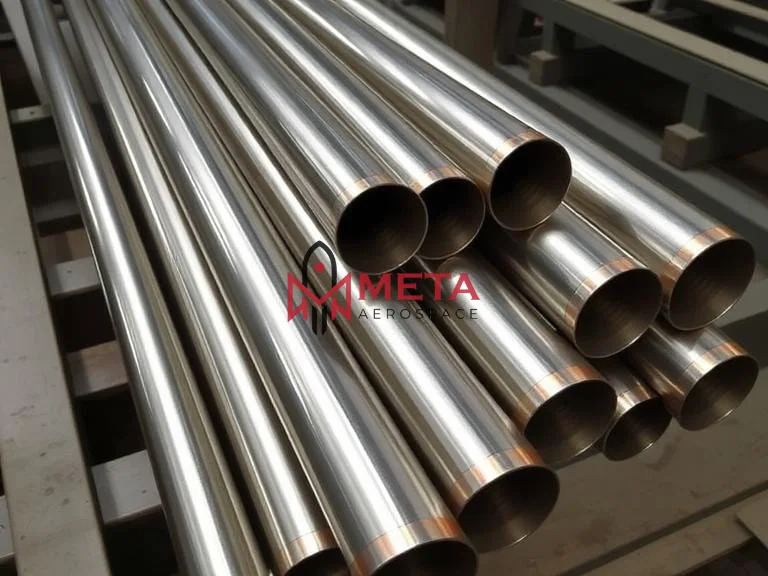

Inconel 825 Pipes

MOQ : 50 Kilograms

Inconel 825 Pipes Specification

- Usage

- Industrial

- Connection

- Welding

- Shape

- Round

- Standard

- ASTM

- Surface Treatment

- Galvanized

- Color

- Sliver

- Warranty

- 1 Year

- Material Grade

- Inconel 825

Inconel 825 Pipes Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1 Kilograms Per Week

- Delivery Time

- 1-2 Week

About Inconel 825 Pipes

What Are Specification Inconel 825 Pipes?

| Standard | ASTM B423/ ASME SB423 |

|---|---|

| Grades | 825 |

| Type | Welded | CDW | ERW | DOM | Seamless | Fabricated | CEW | LSAW |

| End | Screwed, Beveled, Threaded, Plain |

| Length | Single Random, Double Random, Cut to length Suppliers |

| Schedule Thickness Ranges | SCH XS, SCH 40, SCH 80S, SCH 5, SCH 80, SCH XXS, SCH 160, SCH10, All Schedules |

| Surface Finish | 2B, No.1, No.4, No.8 Mirror Finish |

| Sizes | 15" NB TO 150" NB Inner Diameter of Pipe |

| Form | Hydraulic, Square, Rectangular, Round Etc. |

| Delivery Condition | Annealed & Pickled, Polished, Bright & Annealed, etc |

Equivalent material Of Inconel 825 Pipes?

| Grade | UNS No | Old British | Euronorm | GOST | Japanese JIS | ||

|---|---|---|---|---|---|---|---|

| BS | En | No | AFNOR | ||||

| Incoloy 825 | N08825 | NA 16 | NiCr21Mo | 2.4858 | NFE30C20DUM | 703 | NCF 825 |

Chemical Composition Of Inconel 825 Pipes?

| Grade | C | Mn | Si | Fe | S | Cr | Cu | Ti | |

|---|---|---|---|---|---|---|---|---|---|

| 825 | min. | 22.0 | 19.5 | 1.5 | 0.6 | ||||

| max. | 0.05 | 1.0 | 0.5 | 0.015 | 23.5 | 3.0 | 1.2 | ||

Mechanical Properties Of Inconel 825 Pipes?

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 825 | Psi 80,000 , MPa 550 | Psi 32,000 , MPa 220 | 30 | ||

Superior Industrial Performance

Designed for demanding industrial conditions, Inconel 825 pipes offer robust resistance to various corrosive elements. Their galvanized finish enhances longevity and provides added protection against environmental damage, making them a reliable solution for industries like petrochemicals and oil & gas.

Adherence to Stringent Standards

Our Inconel 825 pipes are manufactured in accordance with ASTM standards. This ensures each pipe upholds strict quality requirements, guaranteeing both reliability and compatibility for use in numerous industrial projects and operations across India and globally.

Versatility in Application

With strong weldability and a universal round shape, these pipes are easy to install and integrate into existing systems. They are suitable for a broad spectrum of industries, including chemical processing, desalination plants, and marine engineering.

FAQs of Inconel 825 Pipes:

Q: How are Inconel 825 pipes with galvanized surface treatment used in industrial settings?

A: Inconel 825 pipes with a galvanized surface are primarily used in industries where resistance to corrosion and high temperatures is essential, such as chemical processing, marine applications, and power plants. The galvanized coating provides additional protection against rust and environmental wear.Q: What is the standard followed for manufacturing these Inconel 825 pipes?

A: These pipes are produced according to ASTM standards, which set rigorous guidelines for quality, strength, and consistency, ensuring they meet international benchmarks for industrial piping solutions.Q: When should I choose Inconel 825 pipes over other materials for my project?

A: Inconel 825 pipes are ideal when the application demands remarkable resistance to corrosive substances and high-temperature environments. They are especially recommended for projects exposed to acids, chlorides, and seawater or requiring outstanding durability.Q: Where are your Inconel 825 pipes supplied from, and what regions do you cover?

A: We are headquartered in India and supply Inconel 825 pipes to various regions across the country and export them globally. As a manufacturer, exporter, and supplier, we cover both domestic and international markets.Q: What is the process for connecting these Inconel 825 pipes?

A: These pipes feature welding as the primary connection method. Welding ensures a secure, leak-proof joint, which is essential for high-pressure and corrosive industrial environments.Q: What are the key benefits of using galvanized Inconel 825 pipes for industrial applications?

A: Key benefits include superior corrosion resistance, extended service life, compliance with ASTM standards, and minimal maintenance requirementsresulting in a reliable investment for demanding industrial uses.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Inconel Pipe Category

Inconel 800800H800HT Pipes

Minimum Order Quantity : 50 Kilograms

Connection : Welding

Warranty : 1 Year

Surface Treatment : Galvanized

Standard : ASTM

Usage : Industrial

Inconel 718 Pipes

Minimum Order Quantity : 50 Kilograms

Connection : Welding

Warranty : 1 Year

Surface Treatment : Galvanized

Standard : ASTM

Usage : Industrial

Inconel 601 Pipe

Minimum Order Quantity : 50 Kilograms

Connection : Welding

Warranty : 1 Year

Surface Treatment : Galvanized

Standard : AISI

Usage : Industrial

Inconel Round Pipe

Minimum Order Quantity : 50 Kilograms

Connection : Welding

Warranty : 1 Year

Surface Treatment : Galvanized

Standard : AISI

Usage : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese