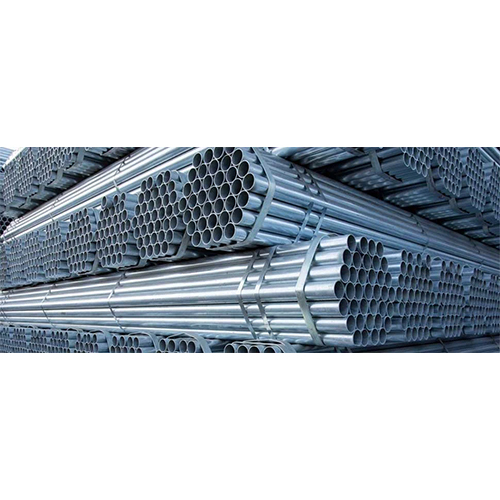

SA 210 Grade A1 Pipes

SA 210 Grade A1 Pipes Specification

- Usage

- Industrial

- Material Grade

- SA 210

- Material

- Steel

- Section Shape

- Round

- Technique

- Hot Rolled

- Surface Treatment

- Galvanized

- Size

- 1/2 NB to 36 NB

- Length

- 3 Meter (m)

- Warranty

- 1 Year

SA 210 Grade A1 Pipes Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1 Kilograms Per Week

- Delivery Time

- 1-2 Week

About SA 210 Grade A1 Pipes

What Are Specification SA 210 Grade A1 Pipes?

| Standards | ASME, ASTM and API |

|---|---|

| Supplier in Thickness | 3-12 millimeter |

| Form | Rectangular, Square, Hydraulic, Round Etc. |

| Schedules | Schedule XXS, 80, 5, 10, 80S, 40, XS, 160, All Schedules |

| Tube Size | 1/2 NB to 36 inch NB |

| Type | Welded / Seamless / Fabricated / ERW |

| End | Plain End, Threaded, Beveled End Manufacturer and Suppliers |

| ASTM A210 Tube Length | Min 3 Meters, Max18 Meters, or according to client's requirement |

| Tolerance | Cold rolled pipe: +/-0.05mm ; Cold drawn pipe: +/-0.1mm |

Chemical Composition Of SA 210 Grade A1 Pipes?

| Grade | C(Max) | Mn | Si(Min) | P(Max) | S(Max) |

| Grade A1 Tube | 0.27 | Max 0.93 | 0.10 | 0.035 | 0.035 |

Mechanical Properties Of SA 210 Grade A1 Pipes?

| Grade | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation(%) |

|---|---|---|---|

| A210 A1 Tube | 415 | 255 | 30 |

Reliable Material and Manufacturing Standards

SA 210 Grade A1 Pipes are manufactured with precision using premium-grade SA 210 steel, ensuring exceptional strength and durability. The hot-rolled production technique further enhances their structural integrity, making these pipes ideal for rigorous industrial use.

Corrosion-Resistant Galvanized Surface

Each pipe undergoes a robust galvanization process, providing excellent protection against rust and environmental corrosion. This treatment ensures a longer lifespan, especially in harsh or moisture-prone industrial settings, while maintaining the pipes mechanical properties.

Flexible Sizing and Versatility for Industrial Use

Available in a wide range of sizes (from 1/2" NB to 36" NB), SA 210 Grade A1 Pipes cater to diverse industrial needs. Their consistent round section shape and standard 3-meter length make them suitable for various installations, piping systems, and engineering projects.

FAQs of SA 210 Grade A1 Pipes:

Q: How are SA 210 Grade A1 Pipes manufactured?

A: SA 210 Grade A1 Pipes are manufactured using the hot-rolled technique, which involves heating the steel and rolling it into the desired round section shape. This process ensures uniformity, enhanced durability, and optimal mechanical properties suitable for industrial applications.Q: What material and surface treatment are used for these pipes?

A: These pipes are made from SA 210 grade steel, known for its high strength and reliability. The surface is galvanized through a protective zinc coating process, which helps prevent rust and extends the pipes service life in challenging industrial environments.Q: Where are SA 210 Grade A1 Pipes commonly used?

A: SA 210 Grade A1 Pipes are widely used in industrial sectors such as power generation, chemical processing, oil and gas, and manufacturing plants where robust, corrosion-resistant piping is required for high-pressure and temperature conditions.Q: When should industries choose SA 210 Grade A1 Pipes?

A: Industries should opt for SA 210 Grade A1 Pipes when they require durable, corrosion-resistant, and reliable piping solutions for demanding operations, particularly those involving steam, high temperatures, or harsh chemicals.Q: What benefits does the 1-year warranty provide?

A: The 1-year warranty ensures peace of mind for buyers by covering potential manufacturing defects. It reflects the manufacturers confidence in the products quality and reliability, making these pipes a secure investment for industrial projects.Q: How does galvanized treatment benefit the pipes?

A: Galvanized treatment involves coating the pipes surface with zinc, which significantly enhances resistance to rust and corrosion. This makes the pipes more durable and reduces maintenance costs over their lifecycle, especially in moisture-rich or corrosive environments.Q: What sizing options are available for SA 210 Grade A1 Pipes?

A: These pipes are available in sizes ranging from 1/2" NB to 36" NB, providing flexibility for a variety of industrial applications. The standard length offered is 3 meters, accommodating different installation and design requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carbon Steel Pipe Category

Carbon ASTM A53 Grade B Pipes

Material : Other, Carbon Steel ASTM A53 Grade B

Technique : Other, Hot Rolled / Cold Drawn / ERW / Seamless

Surface Finish : Other, Painted / Polished / Black / Oiled

Surface Treatment : Other, Galvanized / Black Painted / AntiCorrosion Oil

Standard : Other, ASTM A53 / ASME SA53

Carbon ASTM A672 B60 Pipes

Minimum Order Quantity : 50 Kilograms

Material : Steel

Technique : Hot Rolled

Surface Finish : Polished

Surface Treatment : Galvanized

Standard : ASTM

Carbon ASTM A672 B70 Pipes

Material : Other, Carbon Steel ASTM A672 Grade B70

Technique : Other, Electric Fusion Welded (EFW)

Surface Finish : Other, Black Painted / Bare / Galvanized

Surface Treatment : Other, Anticorrosive Coating / Black Varnished / Galvanized

Standard : Other, ASTM A672 / ASME SA672

ASTM A53 Galvanized Pipe

Minimum Order Quantity : 50 Kilograms

Material : Steel

Technique : Hot Rolled

Surface Finish : Manual Polish

Surface Treatment : Galvanized

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese