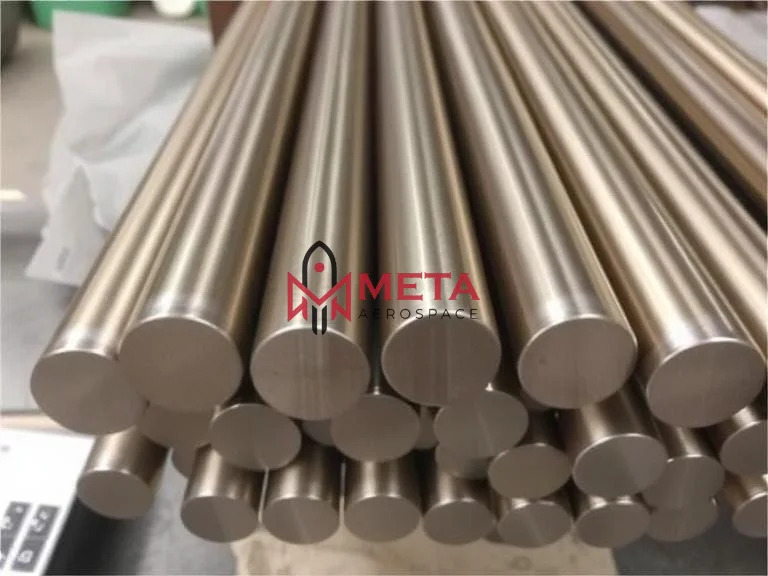

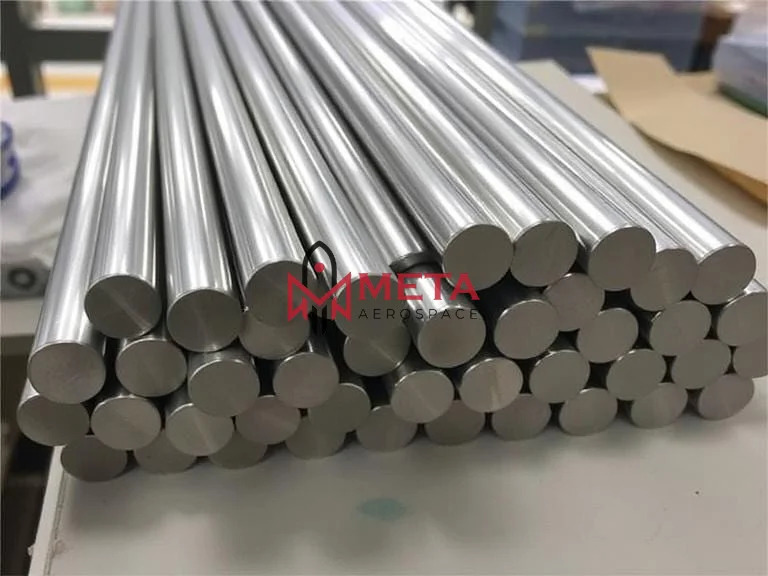

Stainless Steel 13-8 PH Round Bars

Stainless Steel 13-8 PH Round Bars Specification

- Corrosion Resistant

- Excellent

- Product Form

- Hot Rolled / Cold Finished

- Diameter

- 8 mm to 250 mm (available range)

- Size

- Customized / Standard sizes

- Material Composition %

- Cr 12.25-13.25%, Ni 7.5-8.5%, Al 0.85-1.35%, Mo 2.0-2.5%, C max 0.05%

- Tensile Strength

- min 1240 MPa (180 ksi) in H1000 condition

- Recyclable

- Yes

- Heat Resistance

- Yes

- Hardness

- 38-44 HRC (Rockwell)

- Coating Type

- Uncoated / Pickled / Polished

- Product Name

- Stainless Steel 13-8 PH Round Bars

- Steel Type

- Precipitation Hardening Stainless Steel

- Steel Product Type

- Round Bar

- Grade

- 13-8 PH

- Thickness

- Standard as per diameter

- Shape

- Round

- Steel Standard

- ASTM A564, AMS 5629

- Surface

- Bright, smooth

- Composition

- Cr-Ni-Al Stainless Steel with Precipitation Hardening Elements

- Application

- Aerospace, structural components, chemical processing, high-stress environments

- Dimension (L*W*H)

- Custom cut lengths, standard round bar diameters

- Weight

- Varies by diameter and length

- Color

- Silver/Grey Metallic

- Material Grade

- 13-8 PH

- Finish Type

- Bright Polished / Smooth

- Usage

- Machining, Fabrication, High Strength Applications

- Bar Length

- 2 m to 6 m or as required by customer

- Elongation

- min 10% in 50 mm

- Machinability

- Good in solution treated condition

- Density

- 7.8 g/cm

- Condition Supplied

- Solution Annealed (Condition A), H1000, H1150, Customized Heat Treatments

- Magnetism

- Slightly magnetic in certain tempers

- Yield Strength

- min 1170 MPa

About Stainless Steel 13-8 PH Round Bars

What Are Specification Stainless Steel 13-8 PH Round Bars?

| Specification : | ASTM A564 / ASME SA564 |

|---|---|

| Standard : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Round Bars : | Outside Diameter in the range of 4mm to 500mm |

| Hex Bar size : | 2-100mm A/F |

| Bright Bars : | Outside Diameter in the range of 4mm to 100mm |

| Hex Bars : | 18mm 57mm (11/16 to 2-3/4) |

| Square Bars : | 18mm 47mm (11/16 to 1-3/4) |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Length : | 1 to 6 Meters, Custom Cut Lengths |

| Form : | Round, Square, Hex (A/F), Rectangle Etc. |

Equivalent material Of Stainless Steel 13-8 PH Round Bars?

| Alloy | UNS Number | SAE Number |

|---|---|---|

| 13-8 PH | UNS S13800 |

Chemical Composition Of Stainless Steel 13-8 PH Round Bars?

| Cr | Ni | Mo | Al | N | Mn | Si | C | P | S |

|---|---|---|---|---|---|---|---|---|---|

| 12.25 13.23% | 7.50 8.50% | 2.00 2.50% | 0.90 1.35% | 0.010% | 0.10% | 0.10% | 0.05% | 0.010% | 0.008% |

Mechanical Properties Of Stainless Steel 13-8 PH Round Bars?

| Material | Condition | Ultimate Tensile Strength (ksi) | 0.2 % Yield Strength (ksi) | Elongation % in 2D | % Reduction of Area | Rockwell C Hardness |

|---|---|---|---|---|---|---|

| Alloy 15-5 PH Bar AMS 5659 | Cond A | 363 HB max | ||||

| Alloy 15-5 PH Bar AMS 5659 | H900 | 190 | 170 | 10 | 35 | 388-444 |

| Alloy 15-5 PH Bar AMS 5659 | H925 | 170 | 155 | 10 | 38 | 375-429 |

| Alloy 15-5 PH Bar AMS 5659 | H1025 | 155 | 145 | 12 | 45 | 331-401 |

| Alloy 15-5 PH Bar AMS 5659 | H1075 | 145 | 125 | 13 | 45 | 311-375 |

| Alloy 15-5 PH Bar AMS 5659 | H1100 | 140 | 115 | 14 | 45 | 302-363 |

| Alloy 15-5 PH Bar AMS 5659 | H1150 | 135 | 105 | 16 | 50 | 277-352 |

Exceptional Mechanical Properties

13-8 PH round bars boast a minimum yield strength of 1170 MPa and tensile strengths up to 1240 MPa in H1000 condition. Their unique composition of chromium, nickel, and aluminum grants not only remarkable strength but also excellent corrosion and heat resistance, ensuring performance in critical, high-stress applications. With a hardness range of 38-44 HRC, these bars remain reliable under varying mechanical demands.

Versatile Applications Across Industries

These round bars find widespread uses in aerospace manufacturing, chemical processing, and structural engineering, where resistance to corrosion and sustained mechanical strength are essential. Available in customizable diameters, lengths, and heat-treated conditions, 13-8 PH round bars can be tailored to meet specific requirements, making them versatile for precision machining, fabrication, and high-strength component production.

Superior Finish and Ease of Machining

With a bright, polished finish and smooth surface, 13-8 PH round bars offer excellent machinabilityespecially in the solution-treated condition. Their slightly magnetic properties and consistent dimensional tolerances support precision work, while the uncoated, pickled, or polished surfaces promote usability in various industrial processes. These features facilitate fabrication and ensure quality outcomes in high-performance environments.

FAQs of Stainless Steel 13-8 PH Round Bars:

Q: How are Stainless Steel 13-8 PH Round Bars supplied and processed?

A: The bars are available in solution annealed (Condition A), H1000, H1150, or custom heat-treated conditions. They are produced using hot rolled or cold finished methods to meet ASTM A564 and AMS 5629 standards, ensuring optimal mechanical properties for various applications.Q: What makes 13-8 PH stainless steel suitable for high-stress applications?

A: Its compositioncombining chromium, nickel, and aluminumdelivers superior mechanical strength (minimum 1170 MPa yield), excellent corrosion resistance, and sustained hardness, making it ideal for aerospace, structural, and chemical environments where reliability under stress is crucial.Q: When should customized heat treatments be selected for these round bars?

A: Customized heat treatments are recommended when specific mechanical properties, such as yield strength, hardness, or magnetism, are required for specialized industrial applications. Consulting with engineers allows tailoring the bars to project needs.Q: Where are these round bars predominantly used?

A: Stainless Steel 13-8 PH round bars are mainly employed in aerospace components, structural frameworks, chemical process equipment, and other high-strength, corrosive, or heat-resistant environments.Q: What diameters and lengths can be ordered for 13-8 PH round bars?

A: Customers can select bars in standard diameters from 8 mm to 250 mm, with lengths ranging from 2 m to 6 m. Custom sizes are also available based on specific project requirements, supporting flexibility in design and fabrication.Q: How does the magnetic property of 13-8 PH round bars affect usage?

A: The bars are slightly magnetic in certain tempers, particularly after specific heat treatments. This property can be advantageous for certain industrial processes and does not compromise their mechanical or corrosion-resistant qualities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Bars Category

Stainless Steel 316H Round Bars

Hardness : 217 HB max

Steel Type : Other, Austenitic Stainless Steel

Heat Resistance : Yes

Corrosion Resistant : Excellent (suitable for aggressive environments)

Steel Standard : Other, ASTM A276 / ASTM A479

Surface : Bright, Polished, Black, Peeled

Stainless Steel 317 Round Bars

Hardness : 217 HB max

Steel Type : Stainless Steel

Heat Resistance : Yes

Corrosion Resistant : Excellent corrosion and oxidation resistance

Steel Standard : Other, ASTM A276, ASTM A479

Surface : Bright, Polished, Black

Stainless Steel 316L Round Bars

Hardness : Annealed: 217 HB, Max

Steel Type : Other, Austenitic Stainless Steel

Heat Resistance : Yes

Corrosion Resistant : Excellent (chloride and acid environments)

Steel Standard : Other, ASTM A276 / ASTM A479 / EN 100883

Surface : Bright, Smooth, Black, Peeled, Polished

Stainless Steel 347H Round Bars

Hardness : Rockwell B95 max

Steel Type : Other, Austenitic Stainless Steel

Heat Resistance : Yes

Corrosion Resistant : Yes, excellent resistance to intergranular corrosion

Steel Standard : Other, ASTM A276, ASTM A479, ASME SA276, ASME SA479

Surface : Bright, Polished, Black

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese