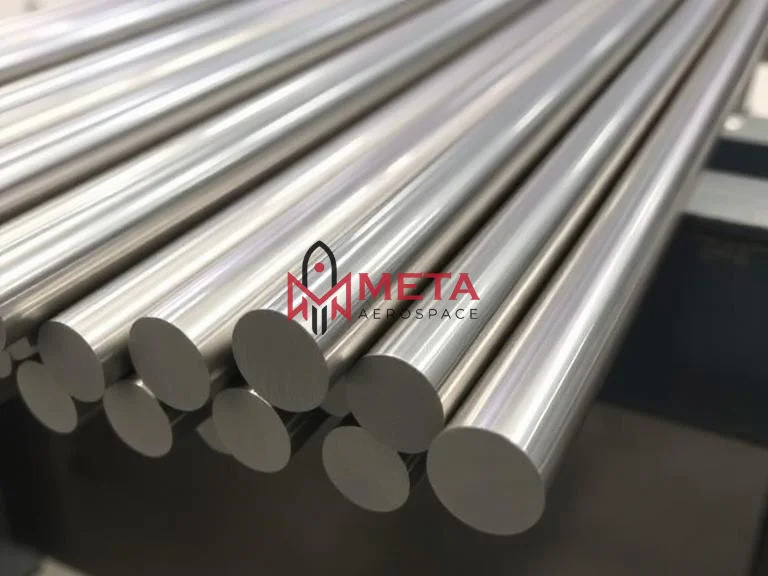

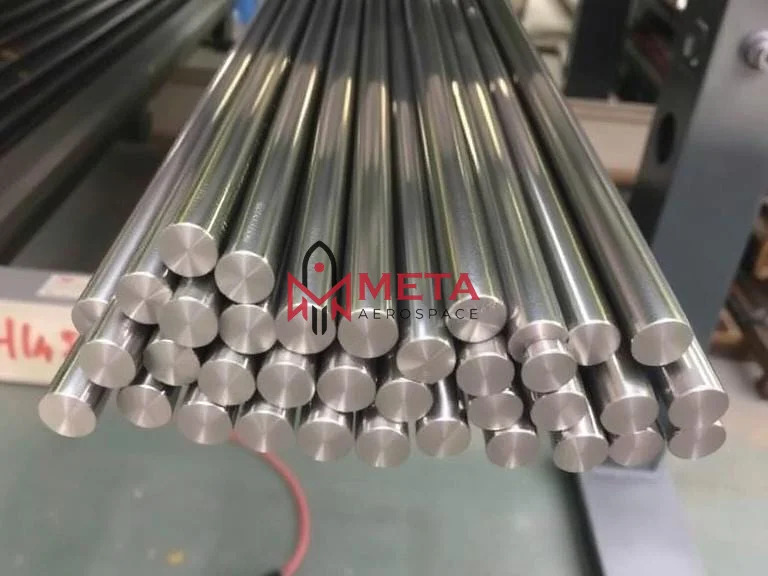

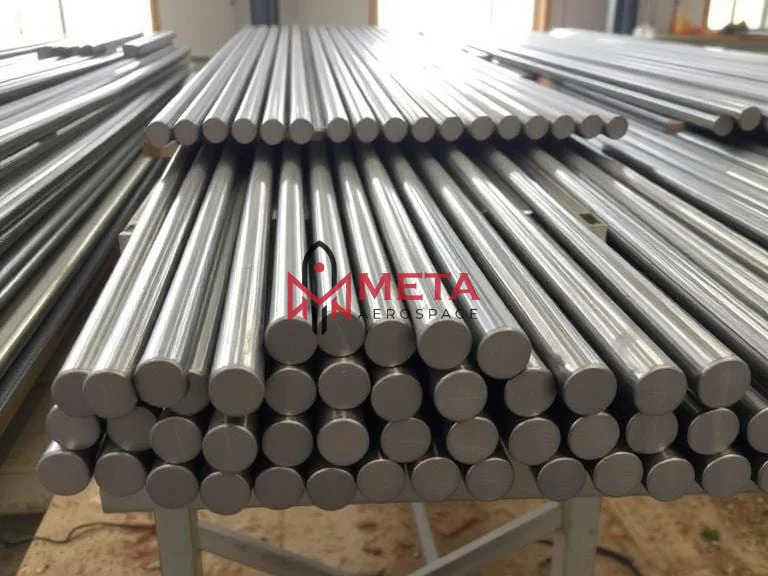

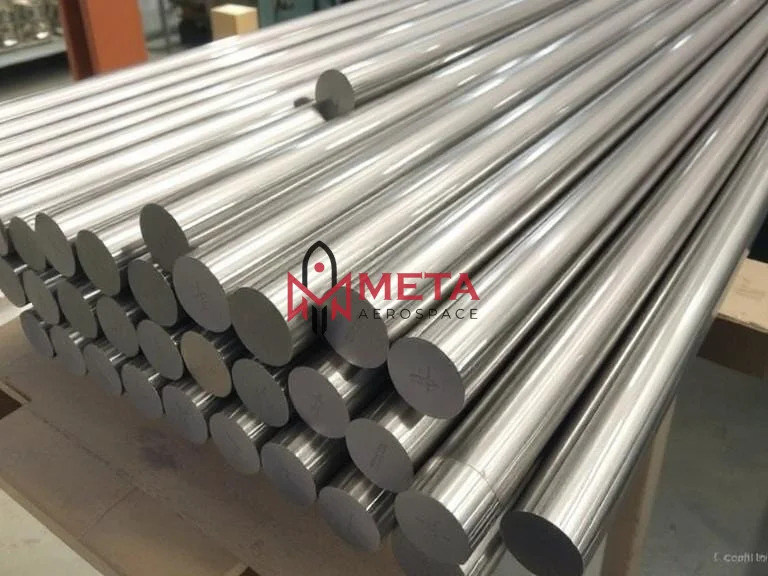

Stainless Steel 347H Round Bars

Stainless Steel 347H Round Bars Specification

- Size

- Custom sizes available

- Corrosion Resistant

- Yes, excellent resistance to intergranular corrosion

- Tensile Strength

- 515 MPa min

- Coating Type

- Uncoated or as specified

- Product Form

- Round Bars

- Heat Resistance

- Yes

- Diameter

- 6mm to 350mm (or as required)

- Recyclable

- Yes

- Hardness

- Rockwell B95 max

- Material Composition %

- Fe Bal., C: 0.10%, Cr: 1719%, Ni: 913%, Si: 0.75%, Mn: 2.00%, S: 0.030%, P: 0.040%, Nb: 10 x C

- Product Name

- Stainless Steel 347H Round Bars

- Steel Type

- Austenitic Stainless Steel

- Steel Product Type

- Round Bar

- Grade

- 347H

- Thickness

- Available in multiple thicknesses (as per order)

- Shape

- Round

- Steel Standard

- ASTM A276, ASTM A479, ASME SA276, ASME SA479

- Surface

- Bright, Polished, Black

- Composition

- Stainless Steel 347H (Fe, C, Cr, Ni, Si, Mn, S, P, Nb)

- Application

- Construction, Chemical Processing, High Temperature Engineering, Power Generation, Petrochemical Industry

- Dimension (L*W*H)

- Customizable as per requirement

- Weight

- Dependent on size and length

- Color

- Silver

- Material Grade

- 347H

- Finish Type

- Bright, Polish, Black

- Usage

- Industrial, Fabrication, Piping, Shafts, General Engineering

- Machinability

- Good

- Magnetic Properties

- Non-magnetic

- Elongation

- 40% min

- Density

- 7.98 g/cm

- Melting Point

- 13981446C

- Weldability

- Excellent

- Bar Length

- 1 to 6 meters or as per customer requirements

- Yield Strength

- 205 MPa min

About Stainless Steel 347H Round Bars

What Are Specification Stainless Steel 347H Round Bars?

| Standard | ASTM A276 / A479, ASME SA276 / A479 |

|---|---|

| Round Bar Size | 3mm~ 800mm |

| Square Bar Size | 4mm* 4mm ~100mm* 100mm |

| Flat Bar Size | 2mm ~ 100mm |

| Hex Bar Size | 2mm ~ 100mm |

| Angle Size | 3mm* 20mm* 20mm~ 12mm* 100mm* 100mm |

| Thickness | 50 mm to 6000 mm Long |

| Length | 1 To 6 Meters, Custom Cut Length |

| Form | Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc |

Equivalent material Of Stainless Steel 347H Round Bars?

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 347H | 1.4961 | S34709 | SUS 347H | - | - | - | X7CrNiNb18-10 |

Chemical Composition Of Stainless Steel 347H Round Bars?

| Grade | C | Mn | Si | P | S | Cr | Co + Ta | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SS 347H | 0.04 0.10 | 2 max | 0.75 max | 0.045 max | 0.03 max | 17 - 20 | 8xC min 1.00 max | 9 - 13 | 62.74 |

Mechanical Properties Of Stainless Steel 347H Round Bars?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1454 C (2650 F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 40 % |

Superior Mechanical and Chemical Properties

347H Stainless Steel Round Bars feature elevated strength and impressive elongation, ensuring reliability under mechanical stress. Their carefully balanced composition prevents intergranular corrosion even at elevated temperatures, making them ideal for critical industrial applications. The non-magnetic, austenitic structure ensures stability and exceptional performance in demanding environments.

Customizable Dimensions for Diverse Applications

Clients can choose from diameters ranging from 6mm to 350mm and lengths between 1 to 6 meters (or per requirements). This flexibility, combined with various surface finishes such as polished, bright, or black, ensures that each round bar precisely fits project specifications in a wide array of industries from general engineering to petrochemical processing.

Optimized for High-Temperature Environments

Withstanding continuous temperatures up to 870C (1600F), 347H round bars are engineered for heat-intensive processes. Their robust design and niobium stabilization offer substantial resistance to thermal degradation, making them a preferred choice for heat exchangers, boilers, and similar high-temperature operations.

FAQs of Stainless Steel 347H Round Bars:

Q: How are Stainless Steel 347H Round Bars used in industrial applications?

A: Stainless Steel 347H Round Bars are widely used in industries such as chemical processing, power generation, and petrochemicals due to their excellent heat and corrosion resistance. They are perfect for fabrication, piping systems, shafts, and structural components operating in high-temperature or corrosive environments.Q: What benefits do Stainless Steel 347H Round Bars offer compared to other stainless steel grades?

A: 347H round bars provide superior resistance to intergranular corrosion and improved mechanical strength at elevated temperatures, thanks to niobium stabilization. Their excellent weldability, machinability, and non-magnetic properties further make them suitable for demanding engineering and construction tasks.Q: When should I choose Stainless Steel 347H Round Bars for my project?

A: Select 347H round bars when your application demands high strength, durability, and resistance to both corrosion and heatespecially in environments exceeding 500C or in chemical processing units subject to oxidizing conditions.Q: Where can Stainless Steel 347H Round Bars be sourced and in what sizes?

A: These round bars are available from a variety of reputable exporters, manufacturers, suppliers, and traders across India, in custom lengths (16 meters or as required) and diameters (6mm350mm), ensuring compatibility with specific project needs.Q: What is the manufacturing process involved for Stainless Steel 347H Round Bars?

A: 347H round bars are produced following ASTM and ASME standards, using precision rolling and heat treatment processes to ensure optimal strength, surface finish, and consistent composition. Customizations for dimensions and finish types are accommodated as per client specifications.Q: How does the non-magnetic property of 347H round bars benefit their usage?

A: The non-magnetic austenitic structure of 347H round bars prevents magnetic interference, making them ideal for use in sensitive equipment and instrumentation often found in the chemical, power, and petrochemical industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Bars Category

Stainless Steel 321H Round Bars

Corrosion Resistant : Excellent resistance to intergranular corrosion

Surface : Bright, Polished, Black, Peeled

Steel Type : Other, Austenitic Stainless Steel

Heat Resistance : Yes

Hardness : 217 HB

Steel Standard : Other, ASTM A276 / ASTM A479 / ASME SA276 / SA479

Stainless Steel 15-5 PH Round Bars

Corrosion Resistant : Yes, good resistance

Surface : Bright / Polished / Peeled

Steel Type : Stainless Steel

Heat Resistance : Yes

Hardness : 2844 HRC (varies with heat treatment)

Steel Standard : Other, ASTM A564 / AMS 5659

Stainless Steel 310 Round Bars

Corrosion Resistant : Excellent

Surface : Bright, Polished, Black, Peeled

Steel Type : Other, Austenitic Stainless Steel

Heat Resistance : Yes

Hardness : 217 HB

Steel Standard : Other, ASTM A276 / A479, EN, JIS, DIN

Stainless Steel 304H Round Bars

Corrosion Resistant : Excellent

Surface : Bright, Polished

Steel Type : Stainless Steel

Heat Resistance : Yes

Hardness : HRB 95 Max

Steel Standard : Other, ASTM A276, ASTM A479

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese