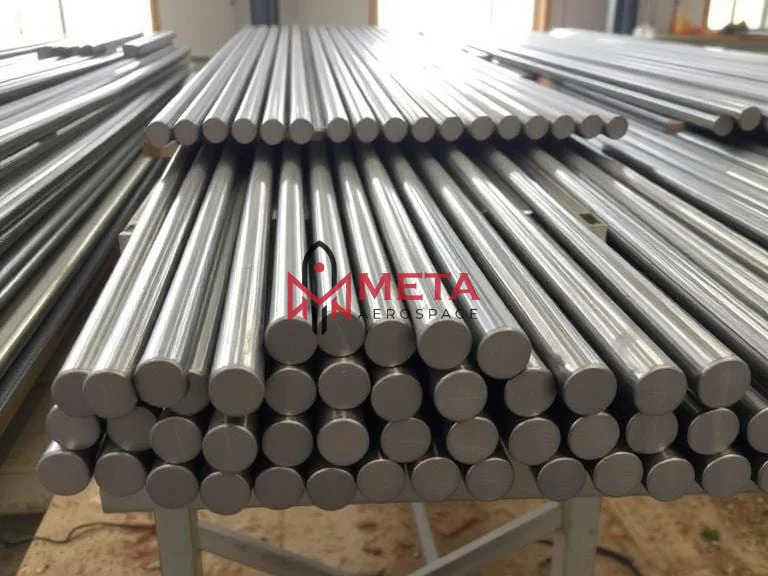

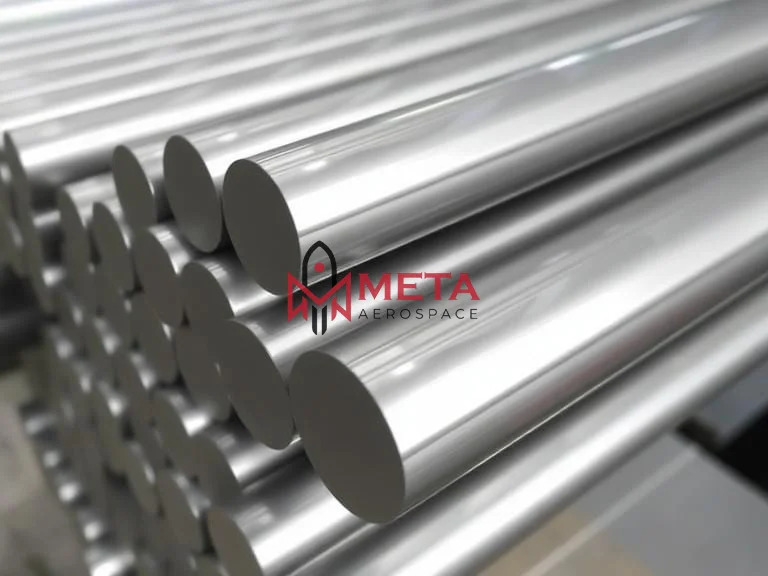

Stainless Steel 15-5 PH Round Bars

Stainless Steel 15-5 PH Round Bars Specification

- Product Form

- Round Bar

- Tensile Strength

- Up to 1380 MPa (200 ksi)

- Recyclable

- Yes

- Diameter

- 6 mm to 300 mm

- Coating Type

- None (Standard finish)

- Corrosion Resistant

- Yes, good resistance

- Size

- Customizable as per order

- Heat Resistance

- Yes

- Material Composition %

- Cr 14-15.5%, Ni 3.5-5.5%, Cu 2.5-4.5%, C max 0.07%, Mn max 1%, Si max 1%, P max 0.04%, S max 0.03%

- Hardness

- 28-44 HRC (varies with heat treatment)

- Product Name

- Stainless Steel 15-5 PH Round Bars

- Steel Type

- Stainless Steel

- Steel Product Type

- Round Bar

- Grade

- 15-5 PH

- Thickness

- As per requirement

- Shape

- Round

- Steel Standard

- ASTM A564 / AMS 5659

- Surface

- Bright / Polished / Peeled

- Composition

- Fe, 15% Cr, 5% Ni, 3.5% Cu, 0.07% C, balance other elements

- Application

- Aerospace, Chemical Processing, Mechanical Components, Nuclear Reactor Components, Marine Applications

- Dimension (L*W*H)

- Custom / As Required

- Weight

- As per Size & Length

- Color

- Silver / Metallic

- Material Grade

- 15-5 PH

- Finish Type

- Bright, Polished, Peeled

- Usage

- Engine Parts, Valves, Shafts, Fasteners, Fittings

- Weldability

- Good, with standard procedures

- Magnetic Properties

- Slightly magnetic in precipitation-hardened condition

- Elongation

- 10-15% (depending on condition)

- Manufacturing Process

- Hot Rolled or Cold Drawn

- Yield Strength

- Minimum 1060 MPa (154 ksi) at H900

- Standards Complied

- ASTM, AMS, ASME, EN, DIN

- Modulus of Elasticity

- 200 GPa (29 x 10^6 psi)

- Machinability

- Good, similar to 304 stainless

- Condition

- Solution Annealed, H900H1150 Heat Treatment Options

- Density

- 7.78 g/cm

About Stainless Steel 15-5 PH Round Bars

What Are Specification Stainless Steel 15-5 PH Round Bars?

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

|---|---|

| Round bar size | Diameter: 3-~800mm |

| Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Billet Size | 1/2 to 495mm Diameter |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Dimensions | Diameter / Height: |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Stainless Steel Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Rod, Round, Channel Bar, T-Bar, Flat Bar, Precision Ground Bar, Blocks, Square, Rings, Round Rod, Triangle, Hollow, Rectangle, Threaded, Hex (A/F), Profiles, Half Round Bar, Ingot, Billet, I/H Bar, Forging etc. |

Equivalent material Of Stainless Steel 15-5 PH Round Bars?

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| SS 15-5PH | 1.4545 | S15500 |

Chemical Composition Of Stainless Steel 15-5 PH Round Bars?

| Grade | C | P | Si | Ni | Al | Fe | Mn | S | Cr | Cb+Ta |

|---|---|---|---|---|---|---|---|---|---|---|

| SS 15-5PH | 0.07 | 0.04 | 1.0 | 3.5 5.5 | Bal | 1.0 | 0.03 | 14.0 15.5 | 0.15 0.45 |

Mechanical Properties Of Stainless Steel 15-5 PH Round Bars?

| Material | Condition | Ultimate Tensile Strength (ksi) | 0.2 % Yield Strength (ksi) | Elongation % in 2D | % Reduction of Area | Rockwell C Hardness |

|---|---|---|---|---|---|---|

| Alloy 15-5 PH Bar AMS 5659 | Cond A | 363 HB max | ||||

| Alloy 15-5 PH Bar AMS 5659 | H900 | 190 | 170 | 10 | 35 | 388-444 |

| Alloy 15-5 PH Bar AMS 5659 | H925 | 170 | 155 | 10 | 38 | 375-429 |

| Alloy 15-5 PH Bar AMS 5659 | H1025 | 155 | 145 | 12 | 45 | 331-401 |

| Alloy 15-5 PH Bar AMS 5659 | H1075 | 145 | 125 | 13 | 45 | 311-375 |

| Alloy 15-5 PH Bar AMS 5659 | H1100 | 140 | 115 | 14 | 45 | 302-363 |

| Alloy 15-5 PH Bar AMS 5659 | H1150 | 135 | 105 | 16 | 50 | 277-352 |

Superior Mechanical Properties

15-5 PH stainless steel round bars combine high tensile and yield strengths with good elongation properties, providing reliability in demanding environments. Heat treatment options from H900 to H1150 allow further customization of mechanical performance, making these bars versatile for both load-bearing and impact-resistant uses.

Versatile Manufacturing and Finishing

Manufactured via both hot rolling and cold drawing, these round bars undergo solution annealing before optional precipitation hardening. The product comes in multiple finishes, such as bright, polished, and peeled, ensuring both aesthetic appeal and surface integrity according to varied application needs.

Extensive Industrial Applications

Thanks to their strength, corrosion resistance, and thermal stability, 15-5 PH round bars are ideal for aerospace, marine, nuclear, and chemical processing sectors. Commonly used in engine parts, valves, shafts, fasteners, and fittings, their adaptability extends across industries requiring robust and durable materials.

FAQs of Stainless Steel 15-5 PH Round Bars:

Q: How are Stainless Steel 15-5 PH Round Bars manufactured?

A: 15-5 PH round bars are produced via hot rolling or cold drawing, followed by solution annealing. They may undergo further heat treatment (H900H1150) to enhance mechanical properties. Finishes include bright, polished, or peeled, depending on the requirement.Q: What benefits does the H900H1150 heat treatment provide?

A: H900H1150 heat treatment improves mechanical strength, hardness, and corrosion resistance of 15-5 PH round bars. It allows customization of hardness (2844 HRC) and yield strength (at least 1060 MPa at H900) for specific applications.Q: When should I consider using 15-5 PH round bars over other stainless steels?

A: Choose 15-5 PH round bars when high strength, good machinability, corrosion resistance, and heat stability up to 600C are requiredespecially in aerospace, marine, and mechanical components where critical performance is essential.Q: Where are 15-5 PH stainless steel round bars typically used?

A: These round bars are widely used in aerospace, mechanical, chemical processing, nuclear reactor, and marine industries. Common applications include shafts, valves, fasteners, engine parts, and various fittings.Q: What is the process for customizing the size and finish of these round bars?

A: Sizes and dimensions can be tailored as per customer requirements, with available diameters ranging from 6 mm to 300 mm. Surface finishes can be bright, polished, or peeled based on the intended use or client specifications.Q: What makes 15-5 PH round bars beneficial for marine and chemical environments?

A: Their excellent corrosion resistance, high strength, and heat resistance make them exceptionally suited for harsh marine and chemical processing environments, ensuring durability and longevity.Q: How does the machinability and weldability of 15-5 PH compare to other stainless steels?

A: 15-5 PH offers good machinability, similar to that of 304 stainless steel, and can be welded using standard procedures, making fabrication and installation more convenient for manufacturers and end users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Bars Category

Stainless Steel 310 Round Bars

Color : Silver/Grey

Composition : 2426% Cr, 1922% Ni, balance Fe, Mn, Si, C, S, P

Steel Product Type : Other, Round Bar

Material Grade : SS 310

Material Composition % : Cr 2426%, Ni 1922%, C 0.25%, Mn 2%, Si 1.5%, S 0.03%, P 0.045%, Fe balance

Heat Resistance : Yes

Stainless Steel 316 Round Bars

Color : Silver Metallic

Composition : Fe, Cr, Ni, Mo

Steel Product Type : Other, Round Bar

Material Grade : 316/316L

Material Composition % : Cr 1618%, Ni 1014%, Mo 23%, C 0.08%, Mn 2%, Si 1%

Heat Resistance : Yes

Stainless Steel 316Ti Round Bars

Color : Silver / Metallic

Composition : CrNiMoTi Stainless Steel

Steel Product Type : Other, Round Bar

Material Grade : 316Ti

Material Composition % : Cr 1618%, Ni 1014%, Mo 23%, Ti 0.5% max, Fe balance

Heat Resistance : Yes

Stainless Steel 321 Round Bars

Color : Metallic Silver

Composition : ChromiumNickel Austenitic Stainless Steel with Titanium

Steel Product Type : Other, Round Bar

Material Grade : 321

Material Composition % : C: 0.08%, Cr: 1719%, Ni: 912%, Ti: 5xC%, Mn: 2%, Si: 1%, P: 0.045%, S: 0.03%

Heat Resistance : Yes

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese