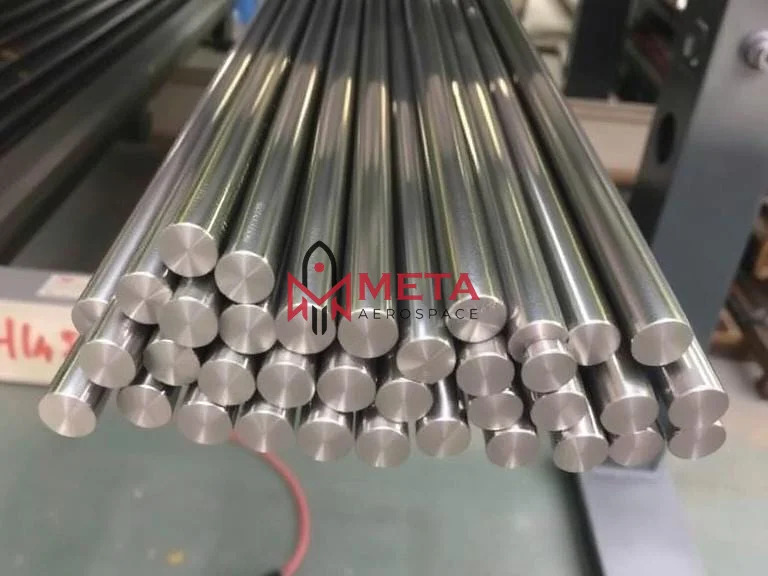

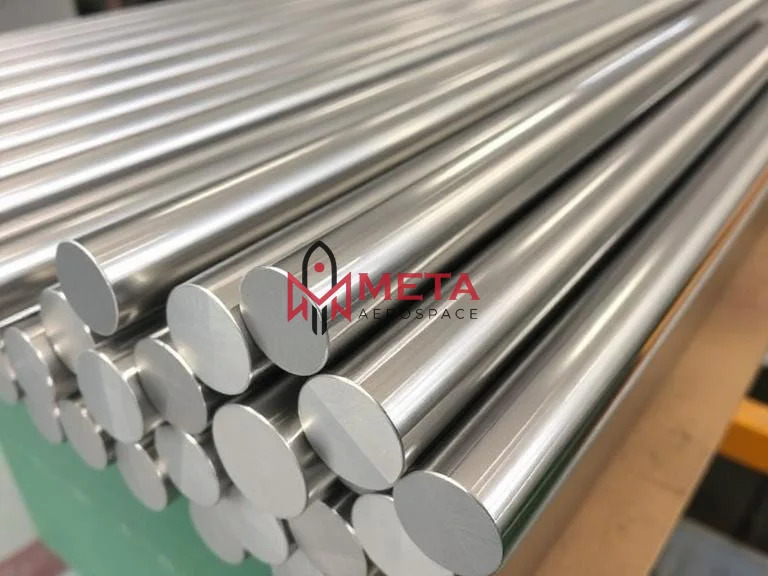

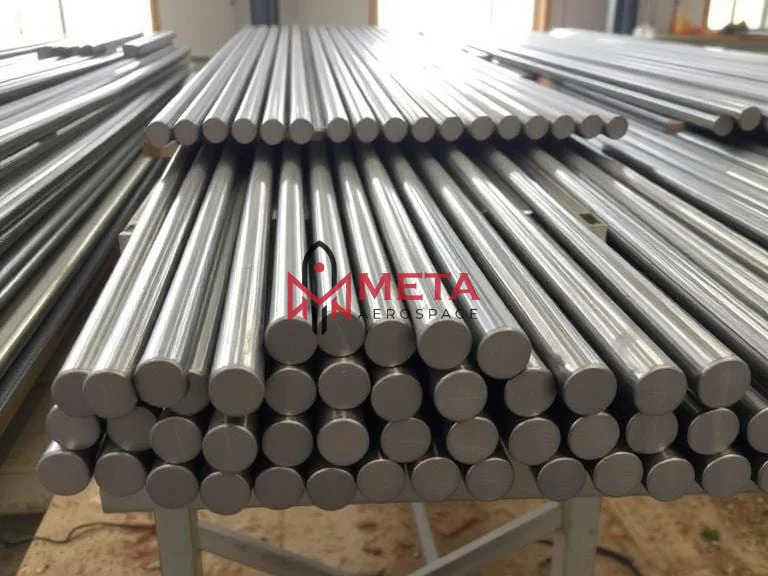

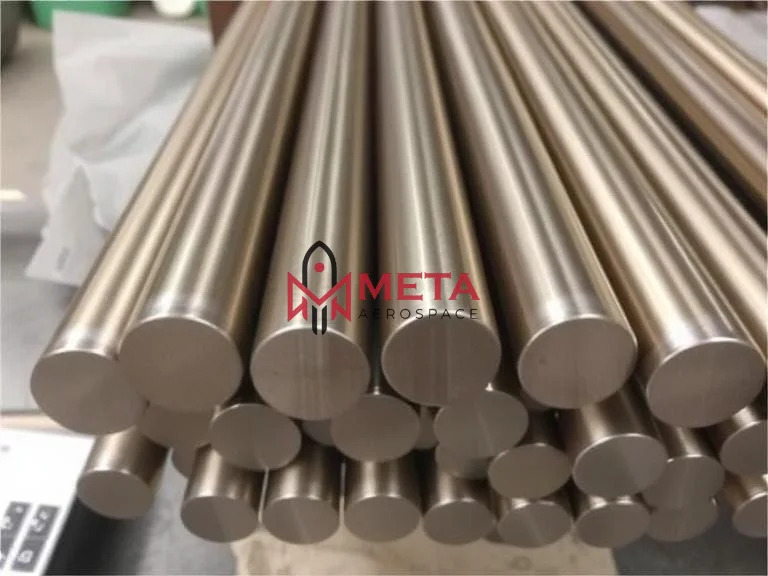

Stainless Steel 321H Round Bars

Stainless Steel 321H Round Bars Specification

- Diameter

- 10 mm 300 mm

- Heat Resistance

- Yes

- Coating Type

- Uncoated / as per customer requirement

- Size

- Customized sizes as per order

- Tensile Strength

- 515 MPa min

- Corrosion Resistant

- Excellent resistance to intergranular corrosion

- Hardness

- 217 HB

- Product Form

- Solid Bar

- Recyclable

- Yes

- Material Composition %

- Cr 17-19%, Ni 9-12%, C 0.04-0.10%, Ti 5xC% min., Mn 2%, Si 1%, P 0.045%, S 0.030%, Fe balance

- Product Name

- Stainless Steel 321H Round Bars

- Steel Type

- Austenitic Stainless Steel

- Steel Product Type

- Round Bar

- Grade

- 321H

- Thickness

- 10 mm to 300 mm

- Shape

- Round

- Steel Standard

- ASTM A276 / ASTM A479 / ASME SA276 / SA479

- Surface

- Bright, Polished, Black, Peeled

- Composition

- Chromium-Nickel with Titanium addition

- Application

- Construction, Oil & Gas Industry, Petrochemical, Power Plants, Heat Exchangers, Chemical Plants, Aerospace, Pharmaceutical Equipment

- Dimension (L*W*H)

- Customizable as per requirement

- Weight

- Dependent on size and length

- Color

- Silver Gray

- Material Grade

- 321H

- Finish Type

- Polished / Annealed

- Usage

- For fabrication in high temperature environments

- Yield Strength

- 205 MPa min

- Density

- 7.9 g/cm

- Magnetic Permeability

- Non-magnetic in annealed condition

- Packing Details

- Export worthy packaging (wooden boxes/crate)

- Lead Time

- Ready stock or 2-4 weeks

- Minimum Order Quantity

- As per supplier/vendor terms

- Melting Point

- 1400 - 1425C

- Available Lengths

- 2 to 6 meters or custom cut

- Machinability

- Good (similar to 304 grades)

- Weldability

- Excellent

- Elongation

- 40% at 50 mm

About Stainless Steel 321H Round Bars

What Are Specification Stainless Steel 321H Round Bars?

| Standard | ASTM A276 / A479, ASME SA276 / A479 |

|---|---|

| Round Bar Size | 3mm~ 800mm |

| Square Bar Size | 4mm* 4mm ~100mm* 100mm |

| Flat Bar Size | 2mm ~ 100mm |

| Hex Bar Size | 2mm ~ 100mm |

| Angle Size | 3mm* 20mm* 20mm~ 12mm* 100mm* 100mm |

| Thickness | 50 mm to 6000 mm Long |

| Length | 1 To 6 Meters, Custom Cut Length |

| Form | Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc |

Equivalent material Of Stainless Steel 321H Round Bars?

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

|---|---|---|---|---|

| SS 321H | 1.4878 | S32109 | SUS 321H | X12CrNiTi18-9 |

Chemical Composition Of Stainless Steel 321H Round Bars?

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

|---|---|---|---|---|---|---|---|---|---|

| SS 321H | 0.04 0.10 | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 - 19.00 | 0.10 max | 9.00 12.00 | 4(C+N) 0.70 max |

Mechanical Properties Of Stainless Steel 321H Round Bars?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1454 C (2650 F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

Enhanced High-Temperature Performance

Stainless Steel 321H Round Bars are engineered for use in situations where exceptional heat resistance and strength are required. Their ability to withstand temperatures up to 900C without loss of mechanical integrity makes them a top choice for fabrication in power plants, chemical facilities, and heat exchangers. The titanium stabilization prevents carbide precipitation, extending their service life even under continuous thermal cycling.

Precision Manufacturing and Customization

Manufactured in accordance with ASTM and ASME standards, these round bars are available in diameters ranging from 10 mm to 300 mm and are supplied in lengths from 2 to 6 meters or as per customer specifications. This flexibility ensures compatibility with a variety of industrial requirements. Surfaces can be tailoredbright, polished, or peeledensuring seamless integration into both functional systems and visible structures.

Guaranteed Quality and Reliable Delivery

Each Stainless Steel 321H Round Bar undergoes stringent quality checks, from compositional analysis to dimensional verification, ensuring compliance with global export standards. Products are securely packaged in wooden crates, protecting them during shipment. With ready stock or a 2-4 week lead time, reliable delivery is assured for both urgent and planned projects anywhere in India or globally.

FAQs of Stainless Steel 321H Round Bars:

Q: How are Stainless Steel 321H Round Bars typically used in industry?

A: These round bars are widely utilized in industries that demand high strength and corrosion resistance at elevated temperatures, such as construction, oil & gas sectors, power plants, heat exchangers, chemical facilities, aerospace, and pharmaceutical equipment manufacturing.Q: What are the key benefits of choosing 321H grade stainless steel round bars?

A: 321H round bars offer excellent intergranular corrosion resistance, superior heat resistance (up to 900C), and stability due to titanium addition, making them ideal for high-temperature fabrication and environments susceptible to thermal cycling.Q: When should I select 321H over other stainless steel grades like 304?

A: 321H is preferred when fabrication and service involve prolonged exposure to high temperatures (above 500C), as it resists carbide precipitation and retains its mechanical properties better than 304, especially in welded structures.Q: Where can I source customized dimensions for 321H round bars?

A: Manufacturers and suppliers in India provide customization services for length, diameter, and surface finish according to client requirements. Dimensions can range from 10 mm to 300 mm diameter and 2 to 6 meters in length or as specified.Q: What is the packaging process for Stainless Steel 321H Round Bars during export?

A: Round bars are packed in export-worthy packaging such as wooden boxes or crates. This packaging ensures the bars are protected from corrosion, mechanical damage, and environmental impact during long-distance transportation.Q: How does the machinability and weldability of 321H compare to other stainless steels?

A: 321H exhibits good machinability, similar to grade 304 stainless steel, and provides excellent weldability, making it easy to fabricate and implement in various industrial projects without special techniques.Q: What makes 321H suitable for high-temperature applications?

A: 321Hs high chromium and nickel content, further enhanced by titanium addition, provides structural stability and prevents sensitization, allowing these bars to maintain mechanical strength in continuous service up to 900C.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Bars Category

Stainless Steel 17-4 PH Round Bars

Grade : 174 PH

Corrosion Resistant : Excellent

Steel Type : Stainless Steel

Hardness : Approx. 2844 HRC (based on heat treatment)

Steel Standard : Other, ASTM A564/A564M, AMS 5643, ASME SA564

Heat Resistance : Yes

Stainless Steel 15-5 PH Round Bars

Grade : 155 PH

Corrosion Resistant : Yes, good resistance

Steel Type : Stainless Steel

Hardness : 2844 HRC (varies with heat treatment)

Steel Standard : Other, ASTM A564 / AMS 5659

Heat Resistance : Yes

Stainless Steel 13-8 PH Round Bars

Grade : 138 PH

Corrosion Resistant : Excellent

Steel Type : Other, Precipitation Hardening Stainless Steel

Hardness : 3844 HRC (Rockwell)

Steel Standard : Other, ASTM A564, AMS 5629

Heat Resistance : Yes

Stainless Steel 321 Round Bars

Grade : 321

Corrosion Resistant : Yes, good resistance to intergranular corrosion

Steel Type : Stainless Steel

Hardness : 201 HB max

Steel Standard : Other, ASTM A276 / ASTM A479

Heat Resistance : Yes

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese