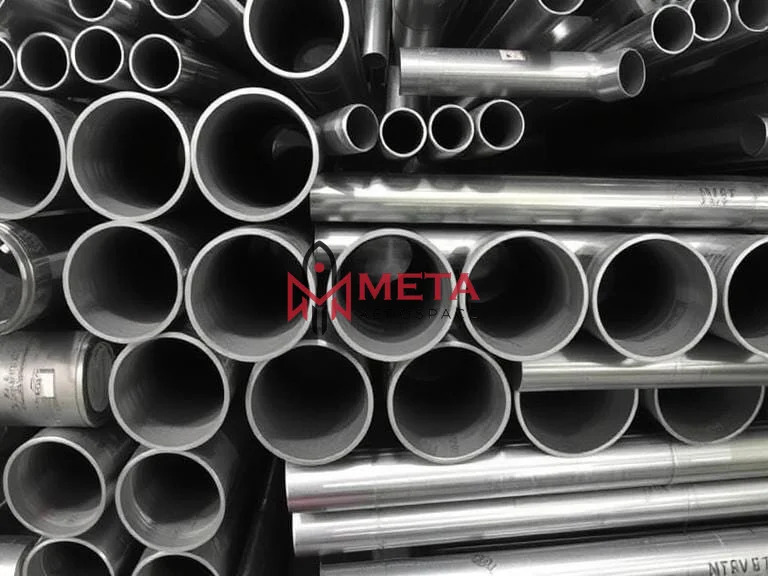

Stainless Steel 316 Pipes

MOQ : 50 Kilograms

Stainless Steel 316 Pipes Specification

- Usage

- Construction

- Surface Finish

- Polished

- Alloy

- Non-Alloy

- Application

- Structure Pipe

- Connection

- Welding

- Material

- Stainless Steel

- Shape

- Round

- Grade

- SS316

- Color

- Sliver

- Warranty

- 1 Year

Stainless Steel 316 Pipes Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1 Kilograms Per Week

- Delivery Time

- 1-2 Week

About Stainless Steel 316 Pipes

What Are Specification Stainless Steel 316 Pipes?

| ASTM / ASME Name | ASTM A 312 ASME SA 312 / ASTM A 358 ASME SA 358 |

|---|---|

| Dimensions Standard | ASTM, ASME and API |

| Stainless Steel 316 Seamless Pipes Size Range | 0.5 NB 16 NB |

| ERW 304 Pipes | 1/2 NB 24 NB |

| EFW 304 Pipes | 6 NB 100 NB |

| OD Sizes | 0.5NB TO 30NB IN |

| Specialized in | Large Diameter Size |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Frequently Used Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| Available Pipes Form | Round |

| Stainless Steel 316 Seamless Pipes Stock Length | Single Random, Double Random & Cut Length. |

| Stainless Steel 316 Seamless Pipes End Finishing | Plain End, Beveled End, Treaded End |

Equivalent material Of Stainless Steel 316 Pipes?

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 316 | 1.4401 | S31600 | SUS 316 | 316S31 | 08KH16N11M3 | Z6CND17-11 / Z7CND17-11-02 / Z7CND17-12-02 | X5CrNiMo17-12-2 |

Chemical Composition Of Stainless Steel 316 Pipes?

| GRADE | C | Mn | Si | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| SS TP316 | 0.08 max | 2 max | 1 max | 0.045 max | 0.030 max | 16 18 | 2 - 3 | 11 14 |

Mechanical Properties Of Stainless Steel 316 Pipes?

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| SS 316 | 485 | 170 | 40 | 92 | 201 |

Durable SS316 Structural Pipes

Engineered for construction, our Stainless Steel 316 Pipes are crafted from high-quality SS316 grade. Their round shape and manually polished surface provide a sleek, silver finish and robust strength, making them ideal for tough environments and welding-based installations.

Versatile Application and Hassle-Free Warranty

These pipes are primarily used for structural support in construction projects across India. Every pipe comes with a one-year warranty, which underscores our commitment to customer satisfaction and product longevity for a wide range of applications.

FAQs of Stainless Steel 316 Pipes:

Q: How are Stainless Steel 316 Pipes installed in construction projects?

A: Stainless Steel 316 Pipes are typically installed through welding, which provides secure and reliable connections in structural frameworks. This process ensures stable support and seamless integration into various construction designs.Q: What are the main benefits of choosing SS316 grade pipes for structural applications?

A: SS316 grade pipes offer exceptional corrosion resistance, mechanical strength, and lasting durability. Their polished finish allows them to withstand harsh environments, making them a preferred choice for construction and structural support.Q: When should I use Stainless Steel 316 Pipes instead of other grades?

A: You should select SS316 pipes for projects demanding high corrosion resistance, such as in coastal or humid environments, or where superior strength and longevity are critical requirements.Q: Where can these stainless steel pipes be sourced in India?

A: Stainless Steel 316 Pipes are available through trusted exporters, manufacturers, suppliers, and traders across India. Leading companies offer comprehensive distribution networks for convenient procurement nationwide.Q: What process is involved in the manual polishing of the pipe surface?

A: Manual polishing is a meticulous process that enhances the pipes surface finish, making it smooth, reflective, and aesthetically appealing. It also removes imperfections, boosting the overall quality and resistance to corrosion.Q: How does the one-year warranty support buyers?

A: The one-year warranty ensures buyers receive pipes free from manufacturing defects or premature failures. It reflects confidence in product quality while providing customers peace of mind during installation and early usage.Q: What typical uses are recommended for these SS316 pipes in construction?

A: These pipes excel as structural supports in buildings, frameworks, and load-bearing applications, especially where exposure to moisture or chemicals necessitates stainless steels superior resilience and longevity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Stainless Steel Pipe Category

Stainless Steel 309 Pipes

Grade : SS 309

Color : Silver / Metallic

Material : Stainless Steel

Technique : Other, Cold Drawn, Hot Rolled

Stainless Steel 347H Pipes

Price 525 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Grade : SS347H

Color : Sliver

Material : Stainless Steel

Technique : Hot Rolled

Stainless Steel 317 Pipes

Price 650 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Grade : SS317

Color : Sliver

Material : Stainless Steel

Technique : Hot Rolled

Stainless Steel 321H Pipes

Minimum Order Quantity : 50 Kilograms

Grade : SS321H

Color : Sliver

Material : Stainless Steel

Technique : Hot Rolled

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese