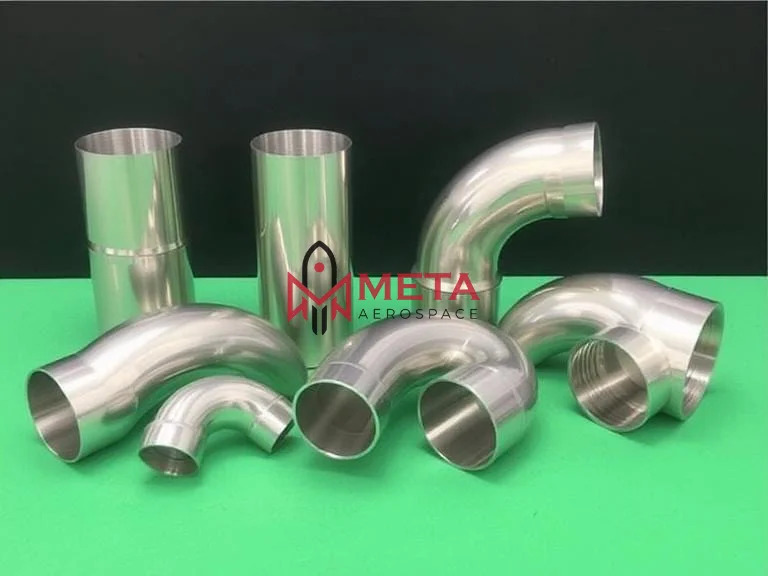

Stainless Steel 316316L316H Pipe Fittings

Stainless Steel 316316L316H Pipe Fittings Specification

- Yield Strength

- 205 MPa min

- Bend Radius

- Standard as per ASME/ANSI

- Tolerance

- 0.5 mm

- Diameter

- Econometric to custom

- Tensile Strength

- 515 MPa min

- Connection Type

- Butt Weld / Socket Weld / Threaded

- Coating Type

- No coating / Custom on request

- Thread Type

- NPT / BSP / BSPT

- Sealing Type

- Metal-to-metal

- Flexibility

- Rigid

- Temperature Range

- -196C to 870C

- Product Type

- Pipe Fittings

- Material

- Stainless Steel

- Connection

- Welded / Seamless / Threaded

- Shape

- Elbow, Tee, Reducer, Coupling, Cap, Cross, Nipple

- Standard

- ASTM A403 / ASME SA403

- Surface Treatment

- Polished / Pickled / Sand Blasting

- Outer Diameter

- 1/8 NB to 48 NB

- Section Shape

- Round

- Length

- As required / Standard lengths

- Thickness

- Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS (as per requirement)

- Color

- Silver

- Usage

- Industrial piping, chemical processing

- Rated Pressure

- Up to 20 MPa (as per size and schedule)

- Material Grade

- 316, 316L, 316H

- Application

- Oil & Gas, Petrochemical, Power Plant, Food Processing, Pharmaceuticals

- Hardness

- Rockwell B: 79 min

- Density

- 7.98 g/cm

- Elongation

- 35% min

- End Connection

- Beveled, Plain, Threaded ends

- Weight

- Varies as per size and schedule

- Corrosion Resistance

- Excellent against acids, chlorides, and marine environments

- Manufacturing Method

- Cold/Hot Formed

- Magnetism

- Non-magnetic in annealed condition

- Packaging

- Wooden cases, Palletized, Custom export packaging

- Testing

- Hydrostatic, Non-destructive, PMI, UT

- Compliance

- RoHS, REACH

About Stainless Steel 316316L316H Pipe Fittings

What Are Specification Stainless Steel 316/316L/316H Pipe Fittings?

| Standards : | ASTM, ASME |

|---|---|

| Designation : | A 403, SA 403 |

| Dimension Standard : | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 |

| Grade : | Stainless Steel 304L Buttweld Pipe Fittings, SS 304L Butt weld |

| Type : | Seamless, Welded |

| Thickness : | Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS |

| Size : | 1/2" to 24" |

| Two Joint / Two Halve 304 Butt weld Fittings Size : | 6" to 48" |

| Types of Butt weld Fittings : | Equal Tee, Nipple, Long Radius Elbow, Reducing Tee, Elbows, Swage Nipple, Short Radius Elbow, Reducer, Barrel Nipple, 90 Deg Elbow, Concentric Reducer, Reducing Nipple, 45 Deg Elbows, Eccentric Reducer, Bend, 180 Deg Elbow, End Cap, 1D Elbow, 3D Elbow, Stubend, 5D Elbow, Cap, Piggable Bend, Long Stubend, Tee, Short Stubend, Long Radius Bend |

Equivalent material Of Stainless Steel 316/316L/316H Pipe Fittings?

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 316 | 1.4301 | S31600 | SUS 316 | 316S31 | 081810 | Z7CN1809 | X5CrNi18-10 |

| SS 316L | 1.4306 / 1.4307 | S31603 | SUS 316L | 3316S11 | 031811 | Z3CN1810 | X2CrNi18-9 / X2CrNi19-11 |

| SS 316H | 1.4948 | S31609 | SUS 316H |

Chemical Composition Of Stainless Steel 316/316L/316H Pipe Fittings?

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 20 | 8 11 | ||

| SS 304L | 0.035 max | 2 max | 1.0 max | 0.045 max | 0.030 max | 18 20 | 8 13 | ||

| SS 304H | 0.10 max | 2 max | 0.75 max | 0.045 max | 0.03 max | 18 20 | 8 10.5 |

Mechanical Properties Of Stainless Steel 316/316L/316H Pipe Fittings?

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| SS 304 | 8.0 g/cm3 | 1400 C (2550 F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| SS 304L | 8.0 g/cm3 | 1400 C (2550 F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

| SS 304H | 8.0 g/cm3 | 1400 C (2550 F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 40 % |

Exceptional Corrosion Resistance

316/316L/316H stainless steel pipe fittings provide excellent durability against acids, chlorides, and harsh marine conditions. Their advanced composition helps maintain integrity even in aggressive chemical environments, making them a trusted solution for industries requiring superior resistance to corrosion and pitting.

Flexible Manufacturing and Finishes

Available in cold or hot formed variants, these pipe fittings offer a range of surface treatments such as polishing, pickling, or sandblasting. You can request custom coating options, or stick with the corrosion-resistant silver finish, ensuring optimal performance and aesthetics for any installation.

Robust Testing and Compliance

Every fitting undergoes strict hydrostatic, non-destructive, PMI, and ultrasonic testing. These rigorous quality controls, alongside compliance with international standards like ASTM A403, ensure reliable performance under high pressure, temperature extremes, and critical applications.

FAQs of Stainless Steel 316316L316H Pipe Fittings:

Q: How are Stainless Steel 316/316L/316H pipe fittings tested for reliability?

A: These fittings undergo hydrostatic, non-destructive, positive material identification (PMI), and ultrasonic testing to verify structural integrity, chemical composition, and leak-proof performance before dispatch.Q: What types of end connections are available for these pipe fittings?

A: You can choose from beveled, plain, or threaded end connections, including NPT, BSP, and BSPT threads, to suit various welding or joining techniques in industrial piping systems.Q: When should I select 316, 316L, or 316H grade fittings for my application?

A: 316 is ideal for general corrosion resistance; 316L is preferred for applications requiring low carbon content to avoid sensitization during welding; 316H is chosen for higher temperature service due to increased carbon content enhancing strength.Q: Where are these fittings commonly used?

A: They are widely utilized in oil and gas, petrochemical, power plants, food processing, and pharmaceutical industries due to their resistance to harsh chemicals, high pressure, and wide temperature ranges.Q: What is the benefit of choosing these fittings for corrosive environments?

A: Their molybdenum-enriched composition offers protection against corrosive agents such as acids and chloride salts, ensuring long service life and minimal maintenance in marine and chemical settings.Q: How are the fittings packaged for export?

A: Pipe fittings are securely packaged in wooden cases, palletized, or tailored in custom export packaging, preventing damage and ensuring safe delivery worldwide.Q: What manufacturing processes are used for these fittings?

A: The fittings are produced using both cold and hot forming techniques, allowing for precise dimensional tolerances (0.5 mm) and a selection of sizes and schedules to accommodate specialized requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Pipe Fittings Category

Stainless Steel 347347H Pipe Fittings

Standard : Other, ASTM A403, ASME SA403

Surface Treatment : Other, Polished / Pickled / Annealed

Material Grade : SS 347, SS 347H

Usage : Piping & Plumbing Systems

Connection : Other, Butt Weld / Socket Weld / Threaded

Material : Other , Stainless Steel 347 / 347H

Stainless Steel 317317L Pipe Fittings

Standard : Other, ASTM A403 / ASME SA403

Surface Treatment : Other, Shot Blasted / Pickled / Polished

Material Grade : SS 317/317L

Usage : Industrial Piping, Chemical Processing

Connection : Other, Welded / Threaded

Material : Other , Stainless Steel 317/317L

Stainless Steel 321321H Pipe Fittings

Standard : Other, ASTM A403, ASME SA403

Surface Treatment : Other, Polished / Pickled

Material Grade : SS 321 / 321H

Usage : Industrial, Chemical, Petrochemical, Oil & Gas

Connection : Other, Butt Weld, Socket Weld, Threaded

Material : Other , Stainless Steel 321/321H

Stainless Steel 304304L Pipe Fittings

Standard : Other, ASTM A403 / ASME SA403

Surface Treatment : Other, Polished / Pickled / Annealed

Material Grade : 304 / 304L

Usage : Piping System, Plumbing, Industrial, Chemical, Petrochemical

Connection : Other, Welded / Buttweld / Threaded

Material : Other , Stainless Steel 304/304L

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese