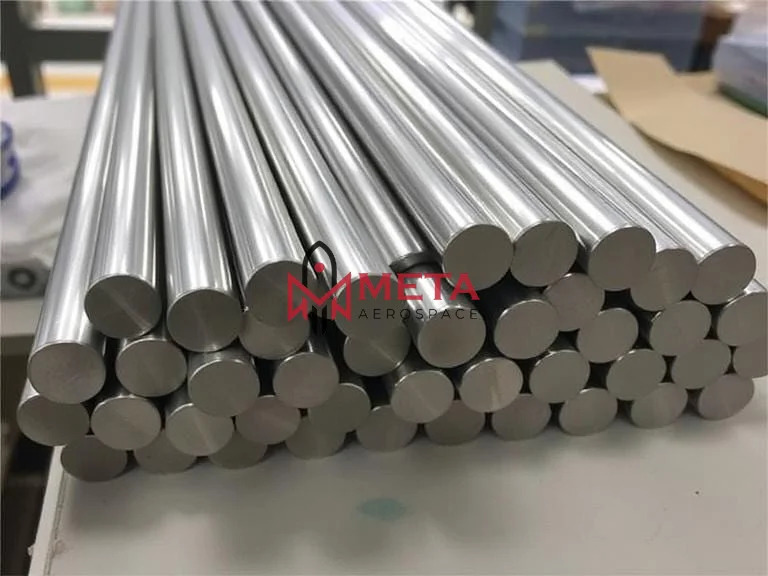

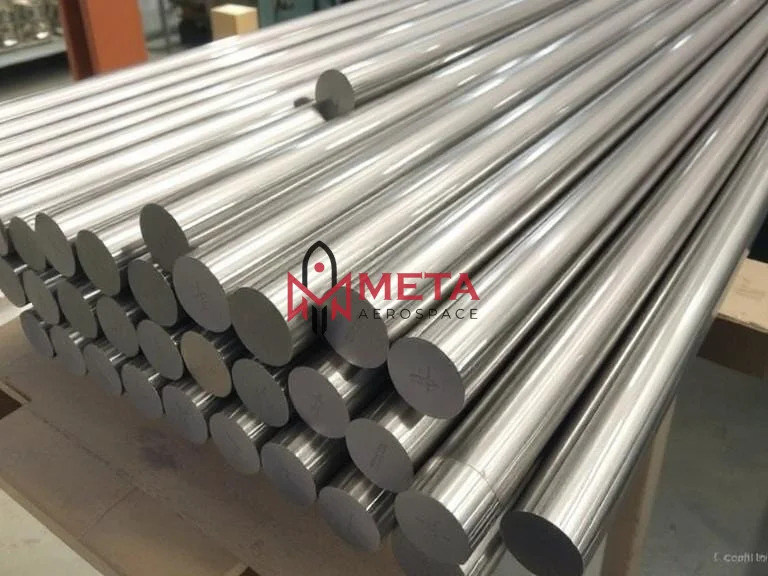

Stainless Steel 317L Round Bars

Stainless Steel 317L Round Bars Specification

- Hardness

- 217 HB max

- Tensile Strength

- 515 MPa min

- Heat Resistance

- Yes

- Material Composition %

- Cr 18-20%, Ni 11-15%, Mo 3-4%, Mn 2%, Si 1%, C 0.03%, P 0.045%, S 0.03%, Fe balance

- Diameter

- 6 mm to 300 mm or as specified

- Coating Type

- Uncoated / as per requirement

- Product Form

- Bar

- Recyclable

- Yes

- Size

- Custom cut or standard lengths (e.g. 1 mtr to 6 mtr)

- Corrosion Resistant

- Excellent against chemicals and chlorides

- Product Name

- Stainless Steel 317L Round Bars

- Steel Type

- Stainless Steel

- Steel Product Type

- Round Bar

- Grade

- 317L

- Thickness

- 6 mm to 300 mm (or as customized)

- Shape

- Round

- Steel Standard

- ASTM A276, A479, ASME SA276, SA479

- Surface

- Bright, Polished, Black, Peeled, Turned

- Composition

- High Chromium-Nickel-Molybdenum alloy

- Application

- Construction, chemical processing, oil & gas, food processing, marine & water supply, paper & pulp industry

- Dimension (L*W*H)

- Customizable as per requirement

- Weight

- Varies as per size and length

- Color

- Silver/Grey

- Material Grade

- 317L

- Finish Type

- Bright / Polished / Peeled / Black

- Usage

- Machining, shafts, fasteners, frameworks, structural purposes

- Minimum Order Quantity

- Negotiable

- Melting Point

- 1400-1450C

- Lead Time

- Ready stock or 730 days depending on order size

- Elongation

- 35% min in 50 mm

- Yield Strength

- 205 MPa min

- Machinability

- Good, can be machined and fabricated

- End Shape

- Plain, Threaded, as per request

- Magnetic Properties

- Non-magnetic in annealed condition

- Packaging Type

- Export worthy bundles or as required by customer

- Delivery Condition

- Annealed / Hot Rolled / Cold Drawn

About Stainless Steel 317L Round Bars

What Are Specification Stainless Steel 317L Round Bars?

| Standard | ASTM A276 / A479, ASME SA276 / A479 |

|---|---|

| Round Bar Size | 3mm~ 800mm |

| Square Bar Size | 4mm* 4mm ~100mm* 100mm |

| Flat Bar Size | 2mm ~ 100mm |

| Hex Bar Size | 2mm ~ 100mm |

| Angle Size | 3mm* 20mm* 20mm~ 12mm* 100mm* 100mm |

| Thickness | 50 mm to 6000 mm Long |

| Length | 1 To 6 Meters, Custom Cut Length |

| Form | Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc |

Equivalent material Of Stainless Steel 317L Round Bars?

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 317L | 1.4438 | S31703 | SUS 317L | - | - | - | X2CrNiMo18154 |

Chemical Composition Of Stainless Steel 317L Round Bars?

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| SS 317L | 0.035 max | 2 max | 1 max | 0.040 max | 0.03 max | 18 - 20 | 3 - 4 | 11 - 15 | - |

Mechanical Properties Of Stainless Steel 317L Round Bars?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1454 C (2650 F) | Psi 75000 , MPa 515 | Psi 30000 , MPa 205 | 35 % |

Superior Chemical and Corrosion Resistance

With significant Chromium, Nickel, and Molybdenum content, Stainless Steel 317L Round Bars excel in resisting aggressive chemicals and chlorides. Their robust composition makes them ideal for marine, chemical processing, and food industries where exposure to corrosive substances is routine. Users benefit from longevity and reduced maintenance costs due to minimal rust formation.

Precise Customization for Diverse Applications

These round bars are available in a variety of diameters, thicknesses, and lengths, tailored to exact project needs. Clients can request specific end shapesplain, threaded, or custom. This flexibility makes them suitable for construction, oil and gas, paper & pulp, frameworks, fasteners, and mechanical shafts.

Reliable Machinability and Fabrication

Stainless Steel 317L Round Bars exhibit good machinability and can be fabricated or welded as required. Delivered in annealed, hot rolled, or cold drawn conditions, they ensure ease of processing during installation. Their sturdy structure maintains integrity even after intensive machining, supporting complex engineering demands.

Exceptional Performance in High Temperatures

317L grade stainless steel demonstrates high heat resistance, enduring temperatures up to 899C. This makes it valuable in demanding environments, including chemical plants and heat-exposed structural frameworks. The stability of mechanical properties at elevated temperatures ensures reliable performance for critical operations.

FAQs of Stainless Steel 317L Round Bars:

Q: How can Stainless Steel 317L Round Bars be processed for specific applications?

A: Stainless Steel 317L Round Bars offer good machinability and can be fabricated through cutting, threading, welding, or other machining processes. They are supplied in annealed, hot rolled, or cold drawn forms, enabling tailored fabrication for shafts, fasteners, frameworks, and structural uses across various industries.Q: What benefits do 317L Round Bars provide in environments exposed to chemicals and chlorides?

A: With a high Chromium-Nickel-Molybdenum alloy content, 317L Round Bars deliver excellent resistance to corrosion, particularly against chemicals and chlorides. This superior durability reduces maintenance costs and prolongs operational life in chemical processing, marine, and food industry settings.Q: When can customers expect delivery of Stainless Steel 317L Round Bars?

A: Delivery depends on the order size. For products in ready stock, dispatch is immediate, while larger or customized orders typically ship within 730 days. Export-quality packaging ensures safe transport, and timelines can be tailored to meet project requirements.Q: Where can Stainless Steel 317L Round Bars be used effectively?

A: These bars are versatile and find use in construction, chemical processing, oil & gas, food processing, marine & water supply, and the paper & pulp industry. Their corrosion resistance and strength make them ideal for both indoor and outdoor structural and mechanical applications.Q: What customization options are available for Stainless Steel 317L Round Bars?

A: Customization is offered in diameter (6 mm to 300 mm), length (from 1 mtr to 6 mtr or as needed), end shape (plain, threaded, or as specified), surface finish (bright, polished, peeled, or black), and coating (uncoated or per requirement). Dimensional and packaging preferences can also be accommodated based on project needs.Q: How does the non-magnetic property of 317L Round Bars benefit certain applications?

A: Non-magnetic behaviour in the annealed condition ensures suitability for sensitive equipment and environments where magnetic interference must be minimized, such as in electronics manufacturing or specialized medical uses.Q: What are the advantages of using Stainless Steel 317L Round Bars over other grades?

A: 317L offers enhanced corrosion and heat resistance due to its molybdenum-enriched composition and low carbon content, making it preferable for harsh environments, weldability, and high-temperature stability compared to conventional grades.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Bars Category

Stainless Steel 304 Round Bars

Steel Standard : Other, ASTM A276, ASTM A479, EN, JIS

Heat Resistance : Yes

Hardness : Brinell 201 HB max

Steel Type : Stainless Steel

Grade : 304

Corrosion Resistant : Excellent

Stainless Steel 317 Round Bars

Steel Standard : Other, ASTM A276, ASTM A479

Heat Resistance : Yes

Hardness : 217 HB max

Steel Type : Stainless Steel

Grade : 317

Corrosion Resistant : Excellent corrosion and oxidation resistance

Stainless Steel 316Ti Round Bars

Steel Standard : Other, ASTM A276, ASTM A479

Heat Resistance : Yes

Hardness : HRB 95 max

Steel Type : Stainless Steel

Grade : 316Ti

Corrosion Resistant : Excellent, especially against chloride environments

Stainless Steel 310 Round Bars

Steel Standard : Other, ASTM A276 / A479, EN, JIS, DIN

Heat Resistance : Yes

Hardness : 217 HB

Steel Type : Other, Austenitic Stainless Steel

Grade : 310

Corrosion Resistant : Excellent

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese