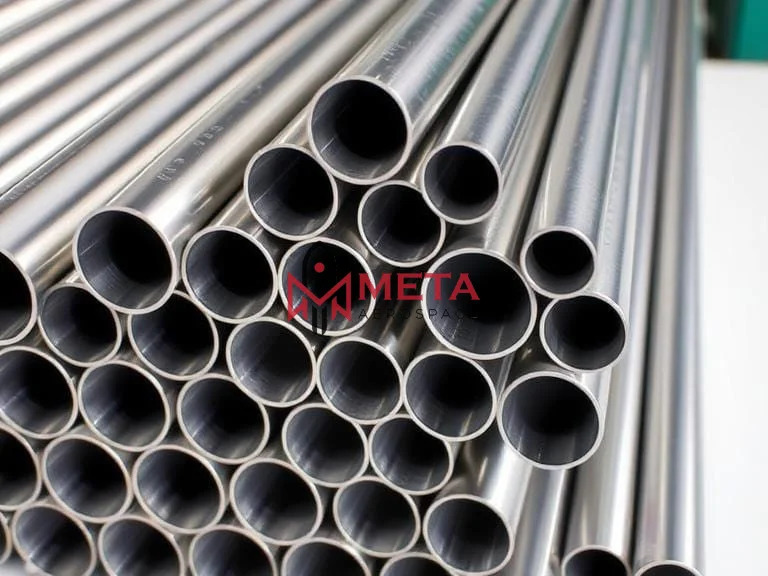

Stainless Steel 347 Pipes

Price 525 INR/ Kilograms

MOQ : 50 Kilograms

Stainless Steel 347 Pipes Specification

- Usage

- Industrial

- Surface Finish

- Polished

- Diameter

- 7 Inch (in)

- Application

- Structure Pipe

- Material

- Stainless Steel

- Steel Grade

- SS347

- Shape

- Round

- Grade

- SS304

- Length

- 6 Meter (m)

- Color

- Sliver

- Warranty

- 1 Year

Stainless Steel 347 Pipes Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1 Kilograms Per Week

- Delivery Time

- 1-2 Week

About Stainless Steel 347 Pipes

What Are Specification Stainless Steel 347 Pipes?

| ASTM / ASME Name | ASTM A 312 ASME SA 312 / ASTM A 358 ASME SA 358 |

|---|---|

| Dimensions Standard | ASTM, ASME and API |

| Stainless Steel 347 Seamless Pipes Size Range | 0.5 NB 16 NB |

| ERW 347 Pipes | 1/2 NB 24 NB |

| EFW 347 Pipes | 6 NB 100 NB |

| OD Sizes | 0.5NB TO 30NB IN |

| Specialized in | Large Diameter Size |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Frequently Used Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| Available Pipes Form | Round |

| Stainless Steel 347 Seamless Pipes Stock Length | Single Random, Double Random & Cut Length. |

| Stainless Steel 347 Seamless Pipes End Finishing | Plain End, Beveled End, Treaded End |

Equivalent material Of Stainless Steel 347 Pipes?

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | BS | GOST | EN |

|---|---|---|---|---|---|---|---|

| SS 347 | 1.4301 | S30409 | - | - | - | - | - |

Chemical Composition Of Stainless Steel 347 Pipes?

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 347 | min. | 0.04 | - | - | - | - | 18 | - | 8 | - |

| max. | 0.1 | 2 | 0.75 | 0.045 | 0.03 | 20 | 10.5 | |||

Mechanical Properties Of Stainless Steel 347 Pipes?

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 347 | 515 | 205 | 40 | 92 | 201 |

Premium Grade Stainless Steel Construction

Our Stainless Steel 347 Pipes are crafted from superior SS347 and SS304 grades, providing exceptional resistance to corrosion and high-temperature stability. Their robust design makes them ideal for industrial and structural applications, ensuring long-lasting performance even in challenging conditions.

High-Quality Finish for Enhanced Durability

Each pipe undergoes a meticulous manual polish to deliver a pristine, polished surface. This finishing not only enhances appearance but also adds an extra layer of protection against environmental wear, contributing to the pipes longevity and reliable usage across various industries.

Versatile Industrial Applications

Perfectly suited for use as structure pipes in large and small-scale industrial projects, these pipes meet the diverse needs of exporters, manufacturers, suppliers, and traders. Their consistent diameter and length make installation straightforward and efficient for a wide array of engineering tasks.

FAQs of Stainless Steel 347 Pipes:

Q: How are Stainless Steel 347 Pipes manufactured to ensure durability?

A: Stainless Steel 347 Pipes are produced using advanced techniques and high-quality SS347 and SS304 materials. The pipes are precision-engineered and then undergo a manual polishing process, which enhances both their strength and resistance to corrosion, ensuring long-term reliability in industrial settings.Q: What is the main application of these Stainless Steel 347 Pipes?

A: These pipes are primarily designed for industrial usage, serving as structure pipes in various engineering projects. Their corrosion resistance and durability make them especially suitable for environments where robust and reliable piping is essential.Q: When should I choose SS347 pipes over standard stainless steel pipes?

A: Opt for SS347 pipes when your application involves exposure to high temperatures or corrosive environments. SS347 offers superior mechanical properties and heat resistance, making these pipes ideal for demanding industrial processes and structures.Q: Where are these Stainless Steel 347 Pipes typically exported and supplied?

A: We export and supply these pipes throughout India and cater to both domestic and international clients. Our network includes manufacturers, suppliers, traders, and exporters ensuring accessibility in all major industrial hubs.Q: What is the process behind the manual polish finish on these pipes?

A: The pipes are manually polished by skilled technicians using refined techniques. This process ensures a smooth and attractive surface, which not only improves the aesthetic appeal but also provides an extra layer of protection against environmental factors.Q: How can these pipes benefit my industrial project?

A: By choosing Stainless Steel 347 Pipes, you ensure reliability, longevity, and resistance to corrosion in your manufacturing or structural applications. Their standardized size and quality finish simplify installation and reduce maintenance costs over time.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Stainless Steel Pipe Category

Stainless Steel 347H Pipes

Price 525 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Material : Stainless Steel

Color : Sliver

Technique : Hot Rolled

Surface Finish : Polished

Stainless Steel 317 Pipes

Price 650 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Material : Stainless Steel

Color : Sliver

Technique : Hot Rolled

Surface Finish : Polished

Stainless Steel 904L Pipes

Minimum Order Quantity : 50 Kilograms

Material : Stainless Steel

Color : Sliver

Technique : Hot Rolled

Surface Finish : Polished

Stainless Steel 304L Pipes

Minimum Order Quantity : 50 Kilograms

Material : Stainless Steel

Color : Sliver

Technique : Hot Rolled

Surface Finish : Polished

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese