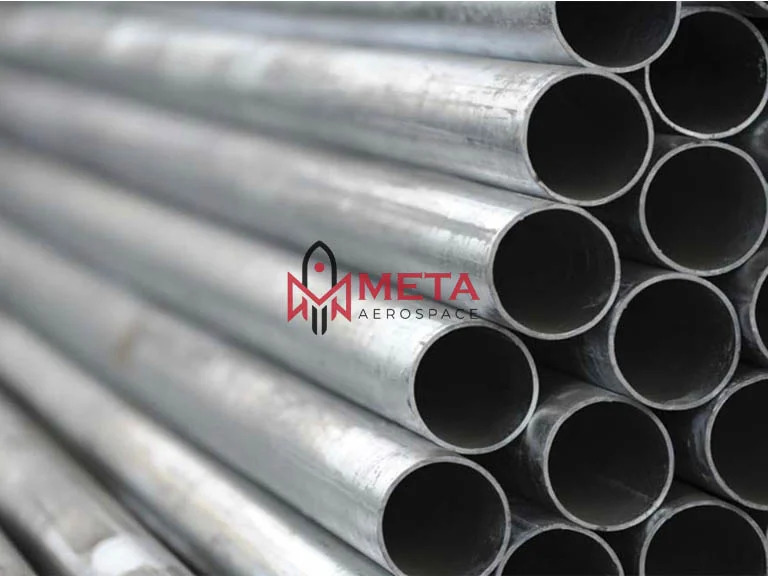

Stainless Steel 304L Pipes

MOQ : 50 Kilograms

Stainless Steel 304L Pipes Specification

- Surface Finish

- Polished

- Usage

- Industrial

- Connection

- Welding

- Application

- Structure Pipe

- Material

- Stainless Steel

- Type

- Seamless

- Grade

- SS304L

- Technique

- Hot Rolled

- Color

- Sliver

- Warranty

- 1 Year

Stainless Steel 304L Pipes Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1 Kilograms Per Week

- Delivery Time

- 1-2 Week

About Stainless Steel 304L Pipes

What Are Specification Stainless Steel 304L Pipes?

| ASTM / ASME Name | ASTM A 312 ASME SA 312 / ASTM A 358 ASME SA 358 |

|---|---|

| Dimensions Standard | ASTM, ASME and API |

| Stainless Steel 304L Seamless Pipes Size Range | 0.5 NB 16 NB |

| ERW 304 Pipes | 1/2 NB 24 NB |

| EFW 304 Pipes | 6 NB 100 NB |

| OD Sizes | 0.5NB TO 30NB IN |

| Specialized in | Large Diameter Size |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Frequently Used Type | Seamless / ERW / Welded / Fabricated / LSAW Pipes |

| Available Pipes Form | Round |

| Stainless Steel 304L Seamless Pipes Stock Length | Single Random, Double Random & Cut Length. |

| Stainless Steel 304L Seamless Pipes End Finishing | Plain End, Beveled End, Treaded End |

Equivalent material Of Stainless Steel 304L Pipes?

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

|---|---|---|---|---|---|---|---|

| BS | En | No | Name | ||||

| 304L | S30403 | 304S11 | 58E | 1.4307 | X5CrNi18-10 | 2332 | SUS 304L |

Chemical Composition Of Stainless Steel 304L Pipes?

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| SS 304L | min. | 18.0 | 8.0 | |||||||

| max. | 0.03 | 2.0 | 1.00 | 0.045 | 0.03 | 20.0 | - | 12.0 | ||

Mechanical Properties Of Stainless Steel 304L Pipes?

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

|---|---|---|---|---|---|

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| SS 304L | 485 | 170 | 40 | 92 | 201 |

Seamless Strength for Industrial Needs

Stainless Steel 304L Pipes offer exceptional durability and seamless construction, making them perfect for rigorous structural applications. Their hot-rolled technique ensures high-pressure resistance and reliable weldability, while the polished surface provides added protection against corrosion, even in harsh conditions. With precise manual finishing, each pipe delivers both strength and aesthetic appeal.

Tailored for Versatile Applications

These pipes are widely used in structural frameworks across multiple industrial sectors. Their SS304L grade composition imparts excellent rust resistance and structural stability. Designed for easy welding and efficient installation, our pipes support engineers and contractors seeking robust, maintenance-friendly solutions for their most critical projects.

FAQs of Stainless Steel 304L Pipes:

Q: How are Stainless Steel 304L Seamless Pipes manufactured?

A: These pipes are created using a hot-rolled technique, which ensures the steel is formed without joints or seams. This seamless production method, combined with manual polishing, results in pipes with superior strength, uniformity, and a polished finish suitable for industrial applications.Q: What are the primary benefits of using SS304L pipes in industrial applications?

A: SS304L pipes offer outstanding corrosion resistance, especially in structural environments where durability and longevity are crucial. Their seamless nature prevents leakages, while the stainless steel grade ensures the pipes withstand high-pressure and harsh conditions.Q: When should I choose seamless SS304L pipes over welded alternatives?

A: Seamless SS304L pipes are recommended when you require higher pressure tolerance, improved strength, and a flawless finish. Theyre ideal for critical industrial settings where leak prevention and structural integrity cannot be compromised.Q: Where can Stainless Steel 304L pipes be used effectively?

A: These pipes are suitable for a variety of industrial structural applications, including in construction frameworks, processing plants, and any scenario requiring robust welded pipe connections. Their manual polished finish makes them adaptable for both visible and concealed uses.Q: What is the warranty coverage for these SS304L pipes?

A: Our Stainless Steel 304L pipes come with a 1-year warranty, which covers manufacturing defects and ensures peace of mind for buyers seeking reliable quality for their projects.Q: How should these pipes be joined or connected during installation?

A: The pipes are designed for welding connections, allowing secure and stable integration into various structural setups. Proper welding ensures longevity and optimal performance in industrial conditions.Q: What surface finish do the pipes have, and why is it important?

A: The pipes are manually polished to achieve a high-quality silver finish. This not only enhances appearance but also improves resistance to environmental factors, making them more durable in challenging industrial environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Stainless Steel Pipe Category

Stainless Steel 304 Pipe

Price 240.0 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Color : Silver

Warranty : 1 Year

Surface Finish : Polished

Usage : Construction

Stainless Steel 316 Pipes

Minimum Order Quantity : 50 Kilograms

Color : Sliver

Warranty : 1 Year

Surface Finish : Polished

Usage : Construction

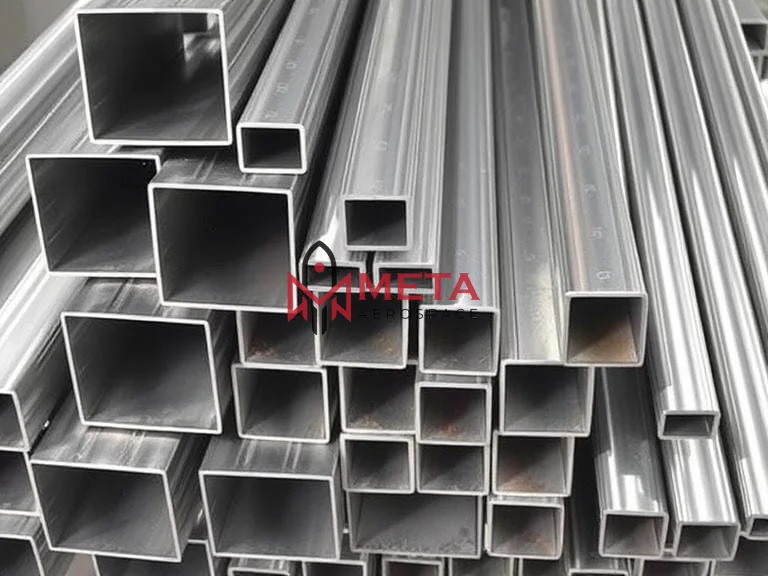

Stainless Steel Square Pipes

Price 265 INR / Kilograms

Minimum Order Quantity : 50 Kilograms

Color : Sliver

Warranty : 1 Year

Surface Finish : Polished

Usage : Industrial

Stainless Steel 310 Pipes

Minimum Order Quantity : 50 Kilograms

Color : Sliver

Warranty : 1 Year

Surface Finish : Polished

Usage : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese