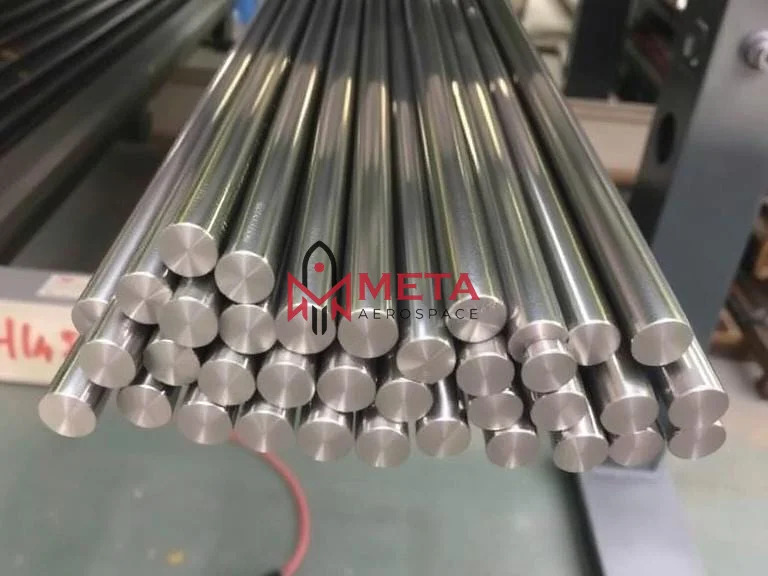

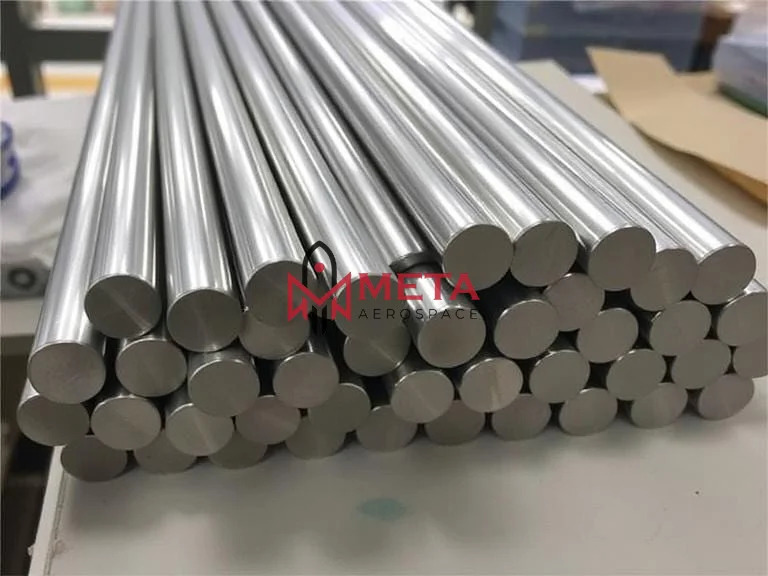

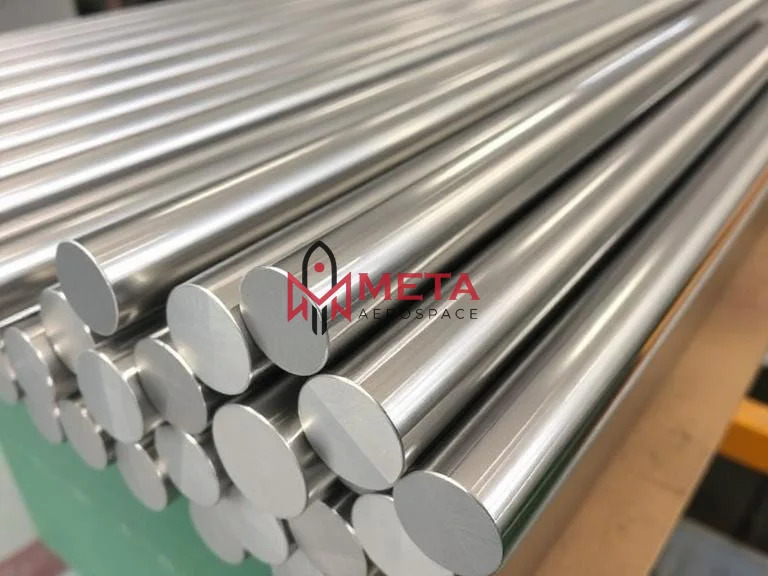

Stainless Steel 904L Round Bars

Stainless Steel 904L Round Bars Specification

- Corrosion Resistant

- Yes, Excellent resistance to acids and chloride stress corrosion

- Recyclable

- Yes

- Hardness

- 220 HB (Brinell Hardness)

- Size

- 6mm to 200mm diameter, custom lengths

- Diameter

- 6mm to 200mm (or custom)

- Material Composition %

- Cr 1923%, Ni 2328%, Mo 45%, Cu 12%, Mn 2%, C 0.02%, P 0.045%, S 0.035%, balance Fe

- Tensile Strength

- 490710 MPa

- Coating Type

- Uncoated/No external coating

- Product Form

- Round Bar

- Heat Resistance

- Yes

- Product Name

- Stainless Steel 904L Round Bars

- Steel Type

- Stainless Steel

- Steel Product Type

- Round Bars

- Grade

- 904L

- Thickness

- Customizable, standard sizes available

- Shape

- Round

- Steel Standard

- ASTM A276, ASTM A479, EN 10088-3

- Surface

- Bright, Polished, Peeled, Black, Matt

- Composition

- 1923% Cr, 2328% Ni, 45% Mo, 12% Cu, max 2% Mn, max 0.045% P, max 0.035% S, max 0.02% C, balance Fe

- Application

- Construction, Chemical Processing, Oil & Gas, Marine, Power Plants, Heat Exchangers, Pharmaceutical Industries

- Dimension (L*W*H)

- As per customer requirement or standard sizes

- Weight

- Varies with size and length

- Color

- Metallic Silver/Grey

- Material Grade

- 904L

- Finish Type

- Polished, Bright

- Usage

- Suitable for high-corrosive environments and process industries

- Density

- 8.0 g/cm

- Inspection

- Third Party Inspection Accepted

- Machinability

- Moderate (requires rigid tools and machining speeds)

- Magnetic Properties

- Non-magnetic (Annealed Condition)

- Storage Recommendations

- Store indoors, dry surface, sealed packaging if possible

- Delivery Condition

- Hot Rolled/Annealed & Pickled/Cold Drawn/Polished

- Packing Type

- Wooden cases, Bundled, or customized as needed

- Elongation

- Min 35% in 50mm

- Weldability

- Excellent with all standard methods

- Melting Point

- 13001390C

- End Finish

- Plain, Bevelled, Threaded ends available

- Standards Compliance

- ASTM, ASME, EN, DIN, JIS

- Minimum Order Quantity

- As per order specification

About Stainless Steel 904L Round Bars

What Are Specification Stainless Steel 904L Round Bars?

| Specifications : | ASTM A276, ASME SA276 / ASTM A479 ASME SA479 |

|---|---|

| Round Bars : | Outside Diameter in the range of 4mm to 500mm |

| Bright Bars : | Outside Diameter in the range of 4mm to 100mm |

| Hex Bars : | 18mm 57mm (11/16 to 2-3/4) |

| Square Bars : | 18mm 47mm (11/16 to 1-3/4) |

| Length : | 1 to 6 Meters, Custom Cut Lengths |

| Form : | Round, Square, Hex (A/F), Rectangle Etc. |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

Equivalent material Of Stainless Steel 904L Round Bars?

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | KS | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 904L | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

Chemical Composition Of Stainless Steel 904L Round Bars?

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Cu |

|---|---|---|---|---|---|---|---|---|---|

| SS 904L | 0.020 max | 2 max | 1 max | 0.040 max | 0.030 max | 19.0-23.0 | 4.0-5.0 max | 23.00 28.00 | 1.0-2.0 |

Mechanical Properties Of Stainless Steel 904L Round Bars?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 7.95 g/cm3 | 1350 C (2460 F) | Psi 71000 , MPa 490 | Psi 32000 , MPa 220 | 35% |

Superior Corrosion and Heat Resistance

904L Stainless Steel Round Bars provide extraordinary resistance against acids, chlorides, and harsh chemical environments. The alloys atomic structure, combined with a balanced mixture of chromium, nickel, molybdenum, and copper, ensures excellent performance up to 400C and protects against chloride stress corrosion cracking, making it a preferred choice for high-corrosive process industries.

Versatile Applications Across Industries

Engineered for versatility, these round bars suit a wide range of sectors including power plants, oil & gas, chemical processing, marine, pharmaceutical, and heat exchanger manufacturing. Their adaptability across indoor and outdoor installations and compatibility with various fabrication methods underscore their value for both structural and process-critical uses.

Quality Standards and Inspection Assurance

Manufactured in compliance with ASTM, ASME, EN, DIN, and JIS standards, every batch of Stainless Steel 904L Round Bars undergoes rigorous quality checks. Third party inspection is offered, ensuring each product meets high-quality benchmarks and maintains safety and reliability in demanding environments.

FAQs of Stainless Steel 904L Round Bars:

Q: How are Stainless Steel 904L Round Bars typically delivered and stored to preserve quality?

A: These bars are delivered in hot rolled, annealed and pickled, cold drawn, or polished conditions, with end finishes including plain, bevelled, or threaded. For optimal preservation, storage should be indoors on dry surfaces and sealed packaging, such as in wooden cases or bundled, is recommended to prevent contamination or corrosion.Q: What makes Stainless Steel 904L Round Bars suitable for use in high-corrosive environments?

A: The alloys compositionrich in chromium, nickel, molybdenum, and copperprovides excellent resistance to acids and chloride-induced stress corrosion. Its non-magnetic nature and bright polished finish further enhance durability in harsh chemical and marine environments.Q: Which industries commonly use Stainless Steel 904L Round Bars and why?

A: Industries such as construction, chemical processing, oil & gas, marine, pharmaceutical, heat exchangers, and power plants value these bars for their exceptional corrosion, heat resistance, and reliable mechanical properties, especially when exposed to aggressive media and elevated temperatures.Q: What standards do Stainless Steel 904L Round Bars comply with, and how does this benefit users?

A: These round bars conform to ASTM, ASME, EN, DIN, and JIS standards, ensuring high quality and consistency in international markets, and providing assurance of performance, compatibility, and safety in critical applications.Q: How can the dimensions and end finishes be customized for project requirements?

A: 904L Round Bars are supplied in diameters from 6mm to 200mm or as per customer specifications, with customizable lengths and a choice of plain, bevelled, or threaded ends. This flexibility enables manufacturers and engineers to match exact application needs.Q: Is Stainless Steel 904L recyclable, and what environmental advantages does it offer?

A: Yes, the product is fully recyclable. Its long service life, resistance to degradation, and the ability to reuse or repurpose the material contribute to sustainable building and equipment practices.Q: What inspection and testing options are available for Stainless Steel 904L Round Bars?

A: Third party inspection is accepted, and bars undergo stringent quality control to ensure compliance with specified standards and mechanical, chemical, and dimensional properties before dispatch.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Bars Category

Stainless Steel 321H Round Bars

Heat Resistance : Yes

Surface : Bright, Polished, Black, Peeled

Product Form : Solid Bar

Steel Type : Other, Austenitic Stainless Steel

Thickness : 10 mm to 300 mm

Finish Type : Polished / Annealed

Stainless Steel 316 Round Bars

Heat Resistance : Yes

Surface : Bright, Black, Peeled, Polished, Annealed

Product Form : Solid round bar

Steel Type : Other, Austenitic Stainless Steel

Thickness : As per diameter; range 6mm to 250mm

Finish Type : Bright, Polished

Stainless Steel 317 Round Bars

Heat Resistance : Yes

Surface : Bright, Polished, Black

Product Form : Solid Round Bar

Steel Type : Stainless Steel

Thickness : Varies as per diameter (available from 4 mm to 350 mm)

Finish Type : Bright, Polished, Black

Stainless Steel 17-4 PH Round Bars

Heat Resistance : Yes

Surface : Bright, Polished, Peeled, Black

Product Form : Round Bar

Steel Type : Stainless Steel

Thickness : 6mm to 300mm (custom sizes available)

Finish Type : Bright, Polished or Custom

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese