Carbon ASTM A333 Grade 6 Pipes

Carbon ASTM A333 Grade 6 Pipes Specification

- Application

- Low Temperature Service, Oil & Gas Industry, Chemical Processing, Power Plant, Petrochemical Industry

- Tolerance

- 1% or as per standard

- Surface Finish

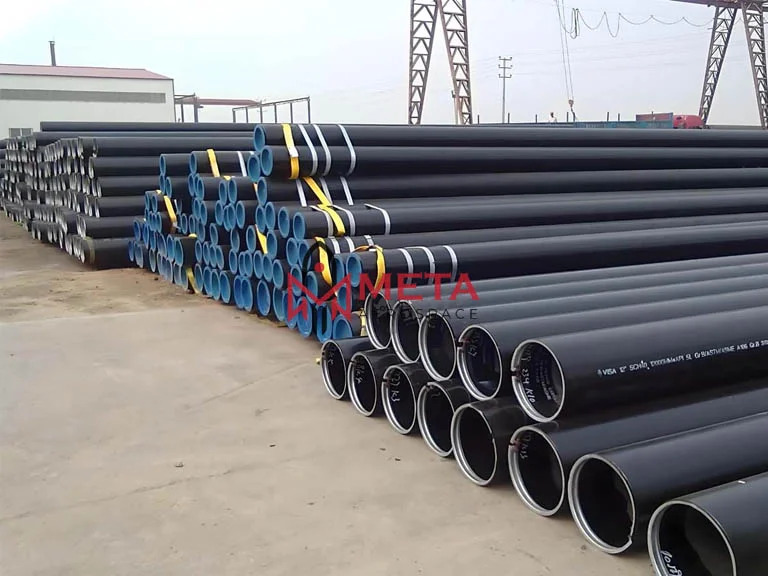

- Polished, Black Painted, Anti-Rust Oil, Annealed

- Connection

- Welded, Threaded, Plain End, Beveled End

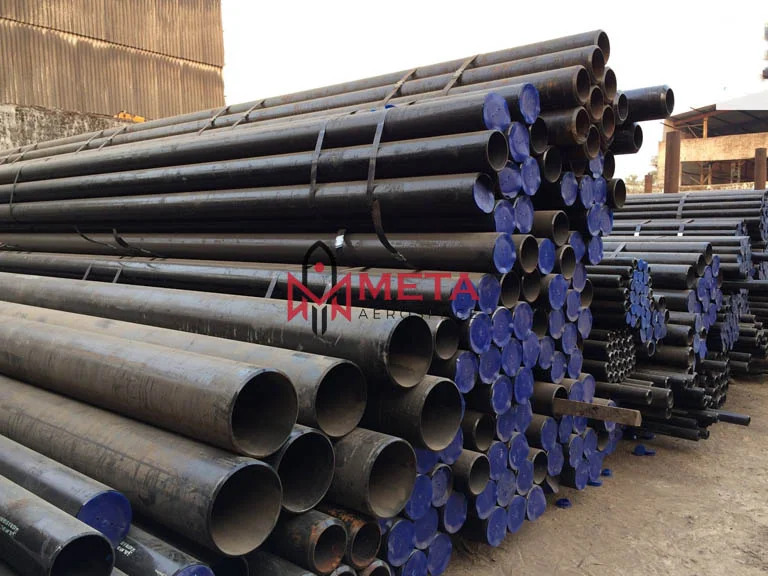

- End Protector

- Plastic Caps

- Product Type

- Carbon Steel Pipe

- Material

- Carbon Steel ASTM A333 Grade 6

- Section Shape

- Round

- Standard

- ASTM A333 Grade 6

- Technique

- Seamless & Welded

- Surface Treatment

- Varnish, Oiled, Black Painted

- Alloy or Not

- Non-Alloy

- Outer Diameter

- 1/2 to 36 (21.3mm to 914mm)

- Thickness

- 2mm to 100mm

- Size

- Customizable as per requirement

- Length

- Single Random, Double Random, or Customized (up to 12 meters)

- Pipe Schedule

- SCH 10, SCH 40, SCH 80, SCH XXS and others

- Heat Treatment

- Normalized, Quenched, and Tempered

- Impact Test

- -45C Charpy V-Notch

- Tensile Strength

- Min 415 MPa

- Inspection

- 100% Hydrostatic & NDT

- Yield Strength

- Min 240 MPa

- Packing

- Bundled with Steel Strips, Plastic Caps, or As Per Client Requirement

- Marking

- Size, Grade, Heat No., Manufacturers Logo

About Carbon ASTM A333 Grade 6 Pipes

What Are Specification Carbon ASTM A333 Grade 6 Pipes?

| Specifications | ASTM A333 ASME SA333 |

|---|---|

| Dimensions | ASTM, ASME and API |

| Size | 1/2 NB to 36 NB |

| Thickness | 3-12mm |

| Schedules | SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules |

| Type | Seamless / ERW / Welded / Fabricated |

| Form | Round, Hydraulic Etc |

| Length | Min 3 Meters, Max18 Meters, or according to customers requirement |

| End | Plain End, Beveled End, Treaded |

Equivalent material Of Carbon ASTM A333 Grade 6 Pipes?

Former | New | |||

|---|---|---|---|---|

Execution | Standard | Material | Standard | Material |

Seamless | ASTM A333 | GRADE 6 | EN 10216-4 | P265NL |

| DIN | EN | BS | NFA | ASTM | ASME |

|---|---|---|---|---|---|

| DIN 17178 Grade FGP 28 | EN P265NL Grade 10216-4 | NFA A 36-2051) Grade A 42 AP | ASTM A333 Grade6 | ASME SA 333 Grade 6 | UNI C20 |

Chemical Composition Of Carbon ASTM A333 Grade 6 Pipes?

| C(max) | Mn | P(max) | S(max) | Si | Ni | |

|---|---|---|---|---|---|---|

| Grade 6 | 0.3 | 0.29 1.06 | 0.025 | 0.025 | 0.10 (min) |

Mechanical Properties Of Carbon ASTM A333 Grade 6 Pipes?

| Grade | Yield strength, min, psi (MPa) | Tensile strength, min, psi (MPa) | Elongation (%) |

|---|---|---|---|

| A333 Gr.6 | 35 000 (240) | 60 000 (415) | 30 min |

Superior Performance in Low-Temperature Environments

ASTM A333 Grade 6 Pipes are engineered to endure low temperatures with excellent impact resistance, validated by Charpy V-Notch testing at -45C. Their robust mechanical properties make them ideal for cryogenic and sub-zero applications where material reliability is critical.

Comprehensive Testing and Quality Assurance

Each pipe undergoes rigorous inspections, including 100% hydrostatic and non-destructive testing (NDT), to guarantee leak-free performance and structural integrity. Detailed marking with size, grade, heat number, and manufacturers logo ensures traceability and authenticity.

Flexible Customization and Application Range

Available in a broad range of schedules (SCH 10 to SCH XXS), thicknesses (2mm to 100mm), diameters (21.3mm to 914mm), and lengths (up to 12 meters), these pipes can be tailored to the specific requirements of projects in oil & gas, power, chemical, and petrochemical industries.

FAQs of Carbon ASTM A333 Grade 6 Pipes:

Q: How are Carbon ASTM A333 Grade 6 Pipes tested for quality assurance?

A: These pipes undergo 100% hydrostatic and non-destructive testing (NDT) procedures to ensure safety and reliability in service. Each piece is inspected for defects, leaks, and mechanical integrity before shipment.Q: What are the advantages of using ASTM A333 Grade 6 Pipes in low-temperature applications?

A: Their high impact resistance at -45C and superior mechanical properties provide safety and durability, making them the preferred choice for cryogenic and sub-zero environments such as power plants and petrochemical facilities.Q: When should heat treatment processes like normalizing and tempering be applied to these pipes?

A: Heat treatment, including normalizing and tempering, is applied according to ASTM standards to enhance toughness, ductility, and strength, particularly for applications where additional resistance to cold cracking is required.Q: Where can ASTM A333 Grade 6 Pipes typically be used?

A: These pipes are extensively used in industries requiring low-temperature resilience, such as oil & gas exploration, power generation, chemical processing, and petrochemical production.Q: What surface treatment options are available for these pipes?

A: Surface treatment options include varnish, oiling, black painting, polishing, and anti-rust oil to protect against corrosion and improve service lifespan, tailored to meet specific project needs.Q: How can the pipes be customized to meet project-specific requirements?

A: Clients can specify outer diameter (from 1/2" up to 36"), wall thickness (2mm to 100mm), length (single, double random, or customized up to 12 meters), and end connection type (plain end, beveled end, threaded, welded), ensuring optimal fit for any application.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Carbon Steel Pipe Category

Carbon ASTM A672 B60 Pipes

Minimum Order Quantity : 50 Kilograms

Technique : Hot Rolled

Material : Steel

Usage : Industrial

Warranty : 1 Year

Surface Treatment : Galvanized

Carbon ASTM A672 C70 Pipes

Minimum Order Quantity : 50 Kilograms

Technique : Hot Rolled

Material : Steel

Usage : Industrial

Warranty : 1 Year

Surface Treatment : Galvanized

ASTM A252 Pipe

Minimum Order Quantity : 50 Kilograms

Technique : Hot Rolled

Material : Steel

Usage : Industrial

Warranty : 1 Year

Surface Treatment : Galvanized

Carbon ASTM A671 CC60 Pipes

Minimum Order Quantity : 50 Kilograms

Technique : Hot Rolled

Material : Steel

Usage : Industrial

Warranty : 1 Year

Surface Treatment : Galvanized

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese