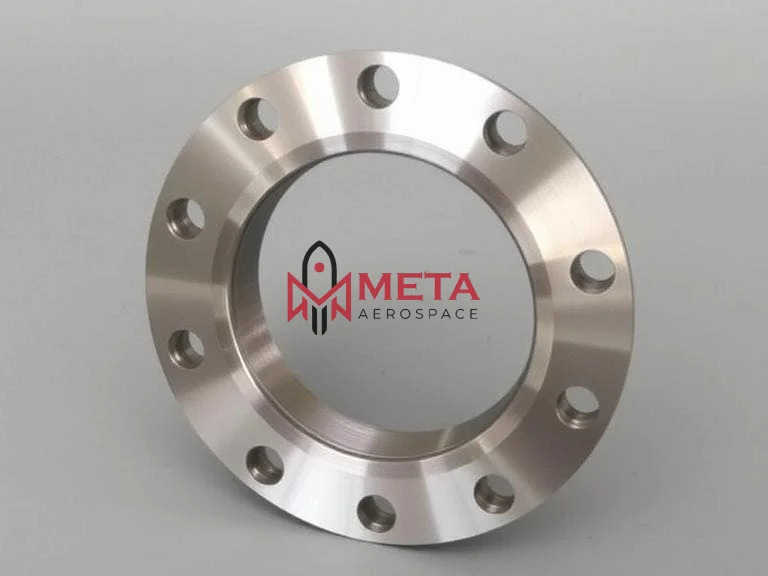

Duplex Steel S31803S32205 Flanges

Duplex Steel S31803S32205 Flanges Specification

- Dimension (L*W*H)

- As per standard or custom requirements

- Purity

- High

- Application

- Oil & Gas, Petrochemical, Power Plant, Chemical Industry, Water Treatment, Marine Engineering

- Grade

- S31803 / S32205

- Feature

- High Strength, Corrosion Resistant, Excellent Weldability

- Product Type

- Flange

- Material

- Duplex Steel S31803/S32205

- Standard

- ASTM A182 / ASME SA182

- Shape

- Round

- Surface

- Shot Blasted / Machined

- Connection

- Welded / Bolted

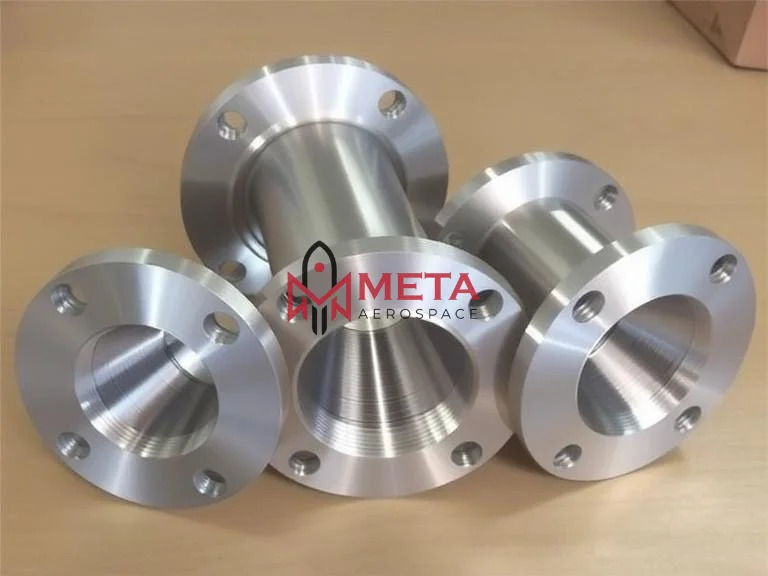

- Technics

- Forged

- Pressure

- 150# to 2500# (PN6 PN400)

- Size

- 1/2 to 24 (DN15 to DN600)

- Color

- Natural / Silver

- Elongation

- 25% min

- Tensile Strength

- 620 MPa min

- Packaging

- Plywood Cases / Pallets

- Yield Strength

- 450 MPa min

- Standards Available

- ANSI, DIN, JIS, EN, BS, GOST

- Temperature Range

- -50°C to +300°C

- Corrosion Resistance

- Excellent against chloride stress corrosion

- Manufacturing Process

- Hot Forged, Heat Treated, Machined

- Density

- 7.8 g/cm³

- End Connection

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

About Duplex Steel S31803S32205 Flanges

What Are Specification Duplex Steel S31803/S32205 Flanges?

| Specifications : | ASTM A182 / ASME SA182 |

|---|---|

| Dimensions : | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size : | 1/8" NB TO 24" NB |

| Class / Pressure : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type : | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Grades : | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

Equivalent material Of Duplex Steel S31803/S32205 Flanges?

| STANDARD | UNS | WERKSTOFF NR. |

|---|---|---|

| Duplex S31803 | S31803 | 1.4462 |

| Duplex S32205 | S32205 | 1.4462 |

Chemical Composition Of Duplex Steel S31803/S32205 Flanges?

| S31803 / S32205 | C | N | P | Si | Mn | Mo | Fe | Cr | S | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| 1.0 | 0.03 | 0.02 | 2.0 | 3.0 - 3.5 | 22.0 - 23.0 | 0.03 | 4.5 - 6.5 | 0.14 - 0.2 | Bal |

Mechanical Properties Of Duplex Steel S31803/S32205 Flanges?

| S31803 / S32205 | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

|---|---|---|---|---|---|

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi - 80000 , MPa - 550 | Psi - 116000 , MPa - 800 | 15 % |

Optimal Material for Challenging Environments

Duplex Steel S31803/S32205 flanges are engineered for demanding applications where both high strength and resistance to harsh corrosive environments are essential. Their microstructure provides excellent durability, especially under exposure to chlorides, making them preferred choices for industries like oil & gas, water treatment, and marine engineering.

Manufacturing Excellence and Precise Engineering

These flanges are produced through hot forging, stringent heat treatment, and precision machining. This meticulous process ensures each product meets the rigorous international standards such as ASTM A182 and ASME SA182 while providing reliable performance in high-pressure and high-temperature conditions.

Versatile Connections and Standards Compliance

Available with Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ) end connections, the flanges fit a wide range of piping systems and pressure classes. Compliance with global standards like ANSI, DIN, and JIS ensures seamless integration in diverse projects and industries across the globe.

FAQs of Duplex Steel S31803S32205 Flanges:

Q: How are Duplex Steel S31803/S32205 flanges manufactured?

A: These flanges are manufactured using a combination of hot forging, heat treatment, and precision machining. This process enhances their mechanical properties, such as strength and durability, while meeting the required standards and specifications for industrial use.Q: What industries commonly use Duplex Steel S31803/S32205 flanges?

A: These flanges are widely used in oil & gas, petrochemical, power plants, chemical processing, water treatment, and marine engineering due to their high strength, corrosion resistance, and suitability for harsh environments.Q: When should I choose Duplex Steel S31803/S32205 flanges over standard stainless steel flanges?

A: Duplex Steel flanges are ideal when your application demands superior resistance to chloride stress corrosion and greater mechanical strength, especially under higher pressures and temperatures ranging from -50C to +300C.Q: Where can these Duplex steel flanges be installed?

A: They can be installed in piping systems within refineries, offshore platforms, water treatment facilities, and chemical plantsessentially any setting where durability and resilience to corrosive elements are required.Q: What benefits do Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ) end connections provide?

A: These end connections offer flexibility to suit different sealing and pressure requirements, ensuring secure and leak-free joints in a wide range of industrial fluid systems.Q: How does the corrosion resistance of these flanges enhance operational life?

A: With excellent resistance to chloride-induced stress corrosion, these flanges greatly reduce the risk of premature failure, ensuring longevity and reducing maintenance needs in aggressive environments.Q: What packaging options are available for shipping these flanges?

A: For safe transportation, flanges are securely packed in plywood cases or pallets, protecting them from mechanical damage and corrosion during transit.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Duplex & Super Duplex Flanges Category

Super Duplex S32750S32760 Flanges

Dimension (L*W*H) : Customizable as per requirement

Standard : Other, ASTM A182 / ASME SA182, DIN, EN, JIS, ANSI, BS

Pressure : Class 150, 300, 600, 900, 1500, 2500 LBS

Shape : Round

Product Type : Other, Flange

Material : Super Duplex Stainless Steel (S32750/S32760)

Zeron 100 Flanges

Dimension (L*W*H) : As per ASME/ANSI B16.5 or customer specification

Standard : Other, ASTM A182, ASTM A240, ASME SA182, ASME SA240, DIN, EN, JIS, BS, UNI, GOST

Pressure : Class 150#, 300#, 600#, 900#, 1500#, 2500#

Shape : Other, Round, Square, Customizable

Product Type : Other, Flange

Material : Zeron 100 (UNS S32760) Super Duplex Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese