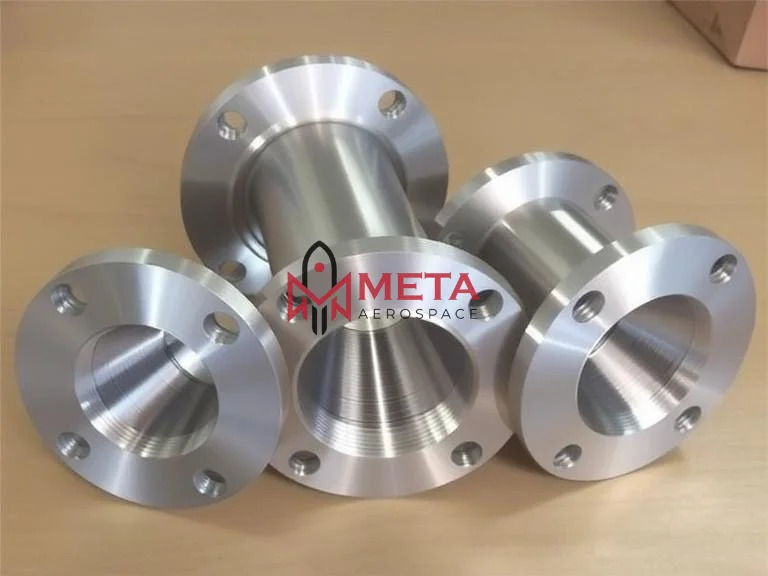

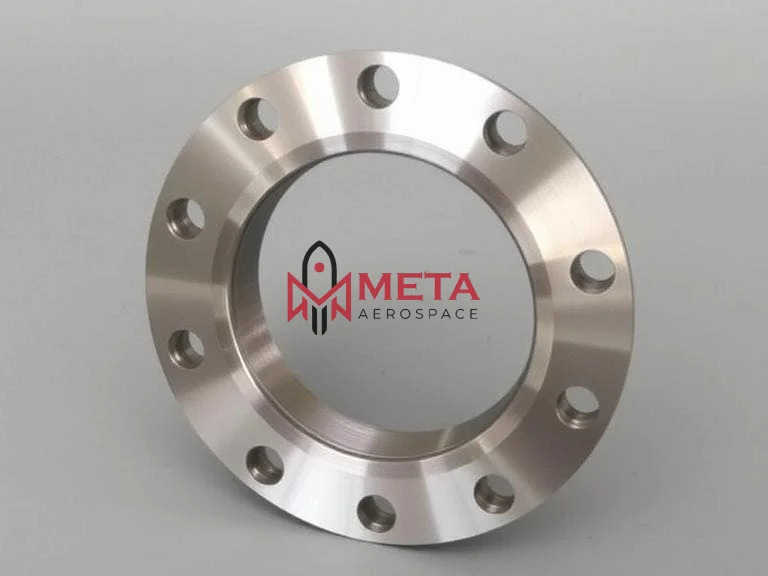

Zeron 100 Flanges

Zeron 100 Flanges Specification

- Dimension (L*W*H)

- As per ASME/ANSI B16.5 or customer specification

- Application

- Oil & Gas, Petrochemical, Desalination, Marine Engineering, Chemical Processing, Pulp & Paper, Power Generation

- Grade

- Zeron 100

- Feature

- High Strength, Excellent Corrosion Resistance, Suitable for Aggressive Environments, Chloride Stress Corrosion Cracking Resistant

- Purity

- 99% Ferrous Alloy

- Product Type

- Flange

- Material

- Zeron 100 (UNS S32760) Super Duplex Stainless Steel

- Standard

- ASTM A182, ASTM A240, ASME SA182, ASME SA240, DIN, EN, JIS, BS, UNI, GOST

- Shape

- Round, Square, Customizable

- Surface

- Machined, Smooth Finish, Pickled

- Connection

- Welded, Threaded, Slip-On, Blind, Socket Weld, Lap Joint, Orifice, Spectacle Blind

- Technics

- Forged, Heat Treated

- Pressure

- Class 150#, 300#, 600#, 900#, 1500#, 2500#

- Size

- 1/2 NB to 24 NB, DN15 to DN600

- Color

- Metallic Silver

- Impact Value

- >40 Joules at -46C

- Temperature Range

- -50C to +300C

- Density

- 7.8 g/cm

- Hardness

- 290 HB max

- Yield Strength 0.2% Proof

- 570 MPa (Min)

- Packaging

- Wooden Cases, Pallet or as per client requirement

- Marking

- Standard marking with size, grade, pressure class, and heat number

- Testing

- Ultrasonic, PMI, Hydrostatic, Destructive, Non-destructive

- Corrosion Resistance

- Excellent pitting and crevice corrosion resistance in chloride environments

- Tensile Strength

- 770 MPa (Min)

- Finish Type

- Custom or Standard Finish (ANSI/DIN/JIS/#150/300 mirror or rough)

- Elongation

- 25% (Min)

- Weldability

- Good weldability with all standard welding processes

About Zeron 100 Flanges

What Are Specification Zeron 100 Flanges?

| Specifications | ASTM A182 / ASME SA182 |

|---|---|

| Size | 1/8 NB TO 48 NB |

| Standards | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Grades | S32750 / S32760 / S32950 |

Equivalent material Of Zeron 100 Flanges?

| Grade | Super Duplex Zeron 100 |

|---|---|

| UNS No | S32760 |

| WERKSTOFF NR. | 1.4410 |

Chemical Composition Of Zeron 100 Flanges?

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 26.00 | 3.00 4.00 | 6.00 8.00 | 0.20 0.30 | 57.61 min |

Mechanical Properties Of Zeron 100 Flanges?

| Tensile Strength, ksi | .2% Yield Strength, ksi | % Elongation in 50mm | Hardness Max. |

|---|---|---|---|

| 109 | 80 | 25 | 28 HRC |

Superior Mechanical Performance

Zeron 100 flanges deliver high tensile (770 MPa min) and yield strength (570 MPa min) while maintaining excellent impact resistance (>40 Joules at -46C). Their elongated ductility (25% min) makes them reliable under dynamic loads, ensuring durability and operational safety even in extreme temperatures and corrosive conditions.

Exceptional Corrosion Resistance

Designed to withstand aggressive chloride environments, Zeron 100 flanges excel in resisting pitting, crevice corrosion, and stress corrosion cracking. This makes them ideal for application in marine, chemical, and desalination setups, extending service life and minimizing maintenance. Their superior alloy composition is a valuable choice for challenging conditions.

Versatile Design and Comprehensive Testing

Available in multiple shapes (round, square, custom), connection types (welded, threaded, slip-on, blind, etc.), and sizes (1/2 NB to 24 NB), Zeron 100 flanges meet diverse industry requirements. Each piece is rigorously testedultrasonic, PMI, hydrostatic, and both destructive and non-destructive methodsensuring the highest quality and compliance.

FAQs of Zeron 100 Flanges:

Q: How are Zeron 100 flanges manufactured and tested for quality assurance?

A: These flanges are forged and heat-treated to achieve their mechanical properties, then machined to precise dimensions. Each flange undergoes robust testing, including ultrasonic, Positive Material Identification (PMI), hydrostatic, and both destructive and non-destructive tests. This comprehensive process ensures they meet stringent quality and safety standards.Q: What are the key benefits of using Zeron 100 flanges in corrosive environments?

A: Zeron 100 flanges offer exceptional pitting and crevice corrosion resistance, especially in chloride-laden environments. Their high strength protects against mechanical failures, while their resistance to stress corrosion cracking ensures secure service in aggressive media, providing long-term reliability and low maintenance needs.Q: Where can Zeron 100 flanges be effectively used?

A: These flanges are ideal for use in industries such as oil & gas, petrochemical, desalination, marine engineering, chemical processing, pulp & paper, and power generation. Their durability and corrosion resistance make them suitable for aggressive and moisture-rich environments.Q: What types of finishes and markings are available for Zeron 100 flanges?

A: Zeron 100 flanges can be supplied with custom or standard finishes, including mirror or rough (ANSI/DIN/JIS/#150/300), and surface options like machined, smooth, or pickled. Standard marking includes size, grade, pressure class, and heat number for complete traceability.Q: How should Zeron 100 flanges be installed and what connections are supported?

A: They can be installed using various connection types, such as welded, threaded, slip-on, blind, socket weld, lap joint, orifice, and spectacle blind. The choice of connection should be based on system requirements and relevant piping standards for optimum performance.Q: What dimensions and pressure classes are available for these flanges?

A: Zeron 100 flanges come in sizes from 1/2 NB to 24 NB (DN15 to DN600) and support pressure classes ranging from 150# to 2500#. Dimensions are as per ASME/ANSI B16.5 or customized according to client specifications.Q: What considerations should be made regarding the packaging and delivery of Zeron 100 flanges?

A: Packaging is tailored to ensure safe transit and delivery, with options including wooden cases and pallets. Custom packaging is also available upon request to meet specific project or logistical needs, ensuring the flanges reach their destination in optimal condition.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Duplex & Super Duplex Flanges Category

Duplex Steel S31803S32205 Flanges

Purity : High

Feature : High Strength, Corrosion Resistant, Excellent Weldability

Technics : Other, Forged

Grade : S31803 / S32205

Material : Duplex Steel S31803/S32205

Connection : Other, Welded / Bolted

Super Duplex S32750S32760 Flanges

Purity : High (As per material standard)

Feature : Corrosion Resistant, High Strength, Durable, High Impact Toughness

Technics : Other, Forged

Grade : S32750 / S32760

Material : Super Duplex Stainless Steel (S32750/S32760)

Connection : Other, Welded, Threaded, Slip On, Blind, Socket Weld, Lap Joint, Orifice, Spectacle Blind, Ring Type Joint

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese