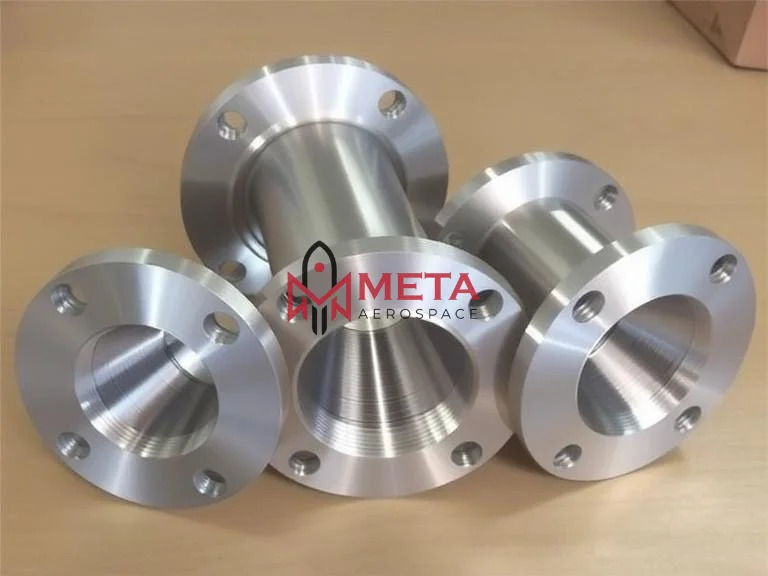

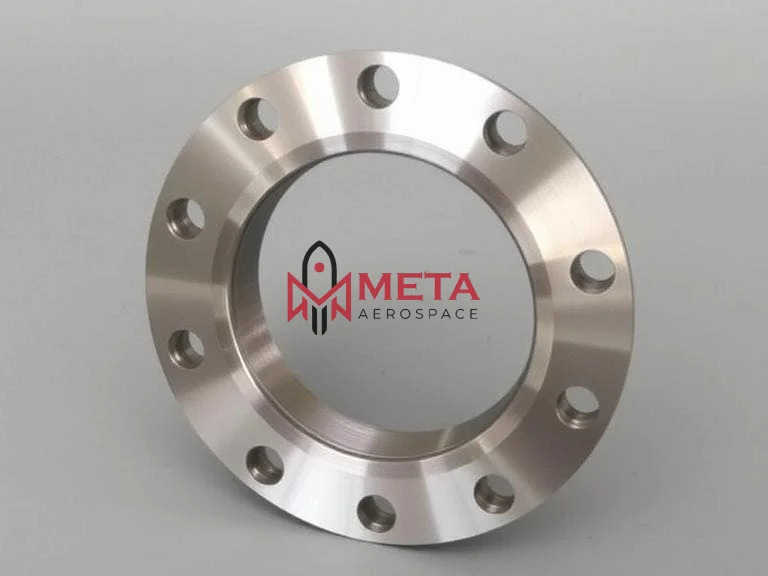

Super Duplex S32750S32760 Flanges

Super Duplex S32750S32760 Flanges Specification

- Application

- Petrochemical Industry, Offshore Platforms, Heat Exchangers, Pulp & Paper, Desalination Plants, Marine Applications

- Grade

- S32750 / S32760

- Dimension (L*W*H)

- Customizable as per requirement

- Feature

- Corrosion Resistant, High Strength, Durable, High Impact Toughness

- Purity

- High (As per material standard)

- Product Type

- Flange

- Material

- Super Duplex Stainless Steel (S32750/S32760)

- Standard

- ASTM A182 / ASME SA182, DIN, EN, JIS, ANSI, BS

- Shape

- Round

- Surface

- Rust-proof Oil, Black Paint, Galvanized, Sand Blasting

- Connection

- Welded, Threaded, Slip On, Blind, Socket Weld, Lap Joint, Orifice, Spectacle Blind, Ring Type Joint

- Technics

- Forged

- Pressure

- Class 150, 300, 600, 900, 1500, 2500 LBS

- Size

- 1/2 to 48 (DN15 to DN1200)

- Color

- Silver / Metallic Grey

- Temperature Range

- -50°C to +300°C

- Testing

- Ultrasonic, PMI, Mechanical and Chemical Testing

- Manufacturing Process

- Hot Forged and Machined

- Standards Compliance

- NACE, IBR, PED Approved

- Ends

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Delivery Condition

- Solution Annealed, Pickled

- Corrosion Resistance

- Excellent resistance to pitting, crevice, and chloride stress corrosion

- Density

- 7.8 g/cm³

- Weldability

- Good (subject to correct procedures)

- Hardness

- 270-290 HB

About Super Duplex S32750S32760 Flanges

What Are Specification Super Duplex S32750/S32760 Flanges?

| Specifications : | ASTM A182 / ASME SA182 |

|---|---|

| Dimensions : | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size : | 1/8" NB TO 24" NB |

| Class / Pressure : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type : | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Grades : | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

Equivalent material Of Super Duplex S32750/S32760 Flanges?

| STANDARD | UNS | WERKSTOFF NR. |

|---|---|---|

| Super Duplex S32750 | S32750 | 1.4410 |

| Super Duplex S32760 | S32760 | 1.4410 |

Chemical Composition Of Super Duplex S32750/S32760 Flanges?

| S32750 / S32760 | C | N | P | Si | Mn | Mo | Ni | Cr | S | Other |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.030 | 0.24/0.32 | 0.035 | 0.80 | 1.20 | 3.0/5.0 | 6.00/8.00 | 24.0/26.0 | 0.020 | Cu:0.50 |

Mechanical Properties Of Super Duplex S32750/S32760 Flanges?

| S31803 / S32205 | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

|---|---|---|---|---|---|

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi - 80000 , MPa - 550 | Psi - 116000 , MPa - 800 | 15 % |

Exceptional Corrosion Resistance

Super Duplex S32750/S32760 Flanges deliver industry-leading resistance to pitting, crevice, and chloride stress corrosion. This exceptional quality, coupled with high mechanical strength, ensures optimal performance in aggressive and corrosive environments such as offshore platforms, marine applications, and chemical processing plants.

Precision Engineering and Quality Assurance

Every flange is hot forged, expertly machined, and solution annealed, providing consistent structural integrity. Intense testing protocols, including ultrasonic, PMI, and mechanical and chemical evaluations, ensure flanges perform reliably under high-pressure and varying temperature environments, with each piece meeting stringent international standards.

Versatile Applications and Customization

These flanges are customizable in dimensions (L*W*H), surface finishes, and connection types such as welded, threaded, slip-on, blind, and more. Their adaptability makes them suitable for critical applications across industries like petrochemical, desalination, pulp and paper, and beyond. Available in standard and custom specifications to meet unique project requirements.

FAQs of Super Duplex S32750S32760 Flanges:

Q: How are Super Duplex S32750/S32760 flanges manufactured and tested for quality?

A: These flanges are produced using hot forging and precision machining, followed by solution annealing and pickling to optimize mechanical and corrosion resistance. Each unit undergoes comprehensive testing, including ultrasonic, Positive Material Identification (PMI), and both mechanical and chemical analysis, ensuring compliance with ASTM, ASME, EN, JIS, and other global standards.Q: What applications typically use Super Duplex S32750/S32760 flanges?

A: Their high corrosion resistance and durability make these flanges ideal for offshore platforms, petrochemical plants, desalination facilities, pulp and paper processing, heat exchangers, and marine industry installations where exposure to chloride and harsh environments is common.Q: When should I select Raised Face (RF), Flat Face (FF), or Ring Type Joint (RTJ) ends?

A: The choice of end type depends on application requirements and industry standards. RF is commonly selected for its pressure and sealing benefits, FF for systems using flat gaskets or low pressure, and RTJ for high-pressure applications, particularly where reliable gasket seating is critical.Q: Where are your Super Duplex S32750/S32760 flanges exported and supplied from?

A: We manufacture, supply, and export these flanges from India to global markets including Europe, the Middle East, Southeast Asia, and beyond, complying with export norms and industry-specific standards for reliable international delivery.Q: What is the typical process for installing these flanges?

A: Installation involves selecting the suitable flange type, ensuring surfaces are clean, correctly aligning and tightening with appropriate bolts or welds based on connection type. Following standard welding procedures is essential for maintaining optimal corrosion and mechanical resistance.Q: How does the superior corrosion resistance benefit my operations?

A: Excellent resistance to pitting, crevice, and chloride-induced stress corrosion reduces maintenance, prevents premature component failure, minimizes downtime, and ensures operational reliability even in harsh environments, ultimately resulting in significant cost savings over the product lifetime.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Duplex & Super Duplex Flanges Category

Zeron 100 Flanges

Grade : Zeron 100

Standard : Other, ASTM A182, ASTM A240, ASME SA182, ASME SA240, DIN, EN, JIS, BS, UNI, GOST

Size : 1/2 NB to 24 NB, DN15 to DN600

Feature : High Strength, Excellent Corrosion Resistance, Suitable for Aggressive Environments, Chloride Stress Corrosion Cracking Resistant

Surface : Other, Machined, Smooth Finish, Pickled

Purity : 99% Ferrous Alloy

Duplex Steel S31803S32205 Flanges

Grade : S31803 / S32205

Standard : Other, ASTM A182 / ASME SA182

Size : 1/2 to 24 (DN15 to DN600)

Feature : High Strength, Corrosion Resistant, Excellent Weldability

Surface : Other, Shot Blasted / Machined

Purity : High

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese