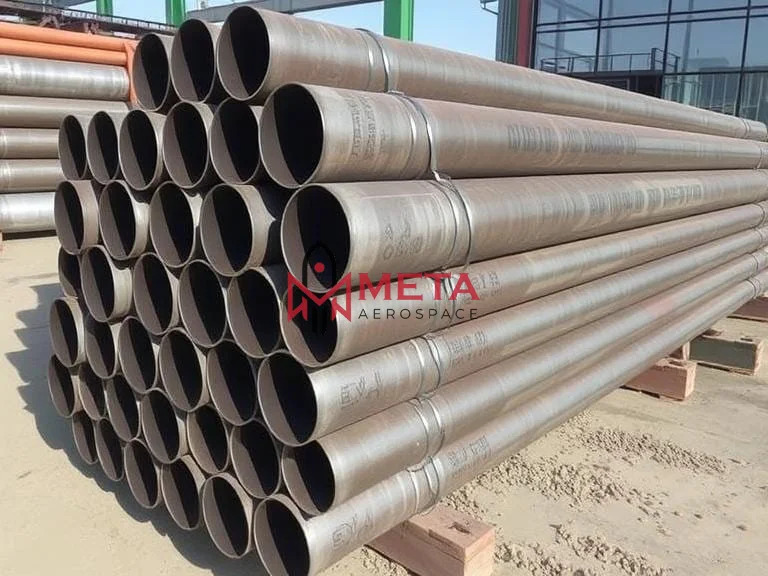

EN 10294-1 Grade E355 Pipes

EN 10294-1 Grade E355 Pipes Specification

- Yield Strength

- 355 N/mm

- Diameter

- As per EN 10294-1

- Tolerance

- +/-1% or as per EN 10294-1 specification

- Tensile Strength

- 580 770 N/mm

- Thread Type

- None unless requested

- Temperature Range

- -20C to 650C

- Flexibility

- Rigid

- Bend Radius

- Subject to wall thickness and diameter

- Coating Type

- None / Oiled / Custom Coating on request

- Connection Type

- Plain / Machined

- Product Type

- Seamless Hollow Bars for Machining

- Material

- Non-alloy Steel

- Connection

- Plain Ends or Machined Ends

- Shape

- Round

- Standard

- EN 10294-1

- Surface Treatment

- Bare, Oiled, or as required

- Outer Diameter

- 21.3 mm - 711 mm

- Section Shape

- Cylindrical / Hollow Bar

- Length

- Custom, Standard 3 to 12 meters

- Thickness

- Up to 80 mm (as per requirement)

- Color

- Metallic/Grey

- Usage

- General Engineering, Precision Machining

- Rated Pressure

- N/A (depends on application)

- Application

- CNC Machining, Structural and Mechanical Use

- Material Grade

- E355 (1.0580)

- Hardness

- 207 HB (Brinell)

- Marking

- Standard as per EN 10294-1 or custom

- Inspection

- Ultrasonic or Eddy Current (upon request)

- Ends

- Square Cut, Chamfered or as per requirements

- Manufacturing Process

- Seamless, Hot Finished or Cold Drawn

- Test Certificates

- EN 10204 3.1 / 3.2 available

- Delivery Condition

- Black, Bright or Oiled

- Machinability

- Good, suitable for further processing

- Heat Treatment

- Normalized or as Rolled

- Density

- ~7.85 g/cm

About EN 10294-1 Grade E355 Pipes

What Are Specification EN 10294-1 Grade E355 Pipes?

| Carbon Steel EN 10294-1 E315 Square bar size | 4 to 100mm |

|---|---|

| Carbon Steel EN 10294-1 E315 Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| EN 10294-1 Grade E355 Hex Bar size | 2-100mm A/F |

| EN 10294-1 Grade E355 Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Carbon Steel EN 10294-1 E315 Rectangles Size | 33 x 30mm to 295 x 1066mm |

| EN 10294-1 Grade E355 Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Steel Grade E315 Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Carbon Steel EN 10294-1 E315 Section | 3.0 to 12.0mm thickness |

| EN 10294-1 Grade E355 Round bar size | Diameter: 3-~800mm |

| EN 10294-1 Grade E355 Carbon Steel Billet Size | 1/2" to 495mm Diameter |

| Steel Grade E315 Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Carbon Steel EN 10294-1 E315 Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| EN 10294-1 Grade E355 Technique | EN 10294-1 Gr E315 Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| CS EN 10294-1 Grade E355 Condition | Hardened & tempered, annealed |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Form | Grade 38Mn6 Carbon Steel Round, Rod, T-Bar, Nickel Alloy Channel Bar, Precision Ground Bar, Nickel Alloy Flat Bar, Nickel Alloy Square Bar, Nickel Alloy Blocks, Nickel Alloy Round Rod, Nickel Alloy Rings, Nickel Alloy Hollow, Nickel Alloy Triangle, Rectangle, Hex (A/F), Nickel Alloy Threaded, Half Round Bar, Profiles, Nickel Alloy Billet, Nickel Alloy Ingot, I/H Bar, Forging etc. |

| Processing | Bar cutting to 650mm |

| Our EN 10294-1 Grade E355 Round bar conforms to NACE MR0175/ISO 15156 | |

Equivalent material Of EN 10294-1 Grade E355 Pipes?

| DIN | EN | BS | NFA | ASTM | ASME |

|---|---|---|---|---|---|

| EN 10294-1 Grade E355 |

Chemical Composition Of EN 10294-1 Grade E355 Pipes?

| Carbon | Silicon | Manganese | Phosphorous | Sulphur | Molybdenum | Nickel | Chromium | Copper | Others |

|---|---|---|---|---|---|---|---|---|---|

| max 0.21 | max 0.30 | max 1.50 | 0.045 | 0.045 |

Mechanical Properties Of EN 10294-1 Grade E355 Pipes?

| Yield Strength | Tensile Strength | Elongation A5 min | |||

|---|---|---|---|---|---|

| MPa min | ksi min | MPa min | MPa min | ksi min | Percentage |

| 450 | 21 | ||||

Versatile Engineering Solutions

EN 10294-1 Grade E355 Pipes are engineered for adaptability across multiple industries, including mechanical engineering and CNC precision machining. Their robust material properties and variety in sizing ensure they cater to many customized requirements, making them a popular choice for manufacturers and structural engineers alike.

Comprehensive Manufacturing and Quality Control

These pipes undergo seamless manufacturingeither hot finished or cold drawnfollowed by strict heat treatment procedures such as normalization or as-rolling. Every batch is meticulously inspected, with Ultrasonic or Eddy Current testing available upon request, and certified as per EN 10204 3.1 / 3.2, ensuring the highest quality standards for end-users.

Customizable Features for Specific Applications

With options for ends, surface treatments, and lengths, EN 10294-1 Grade E355 Pipes can be tailored to project specifications. Customers can choose from square cut, chamfered, or custom ends, as well as finishes ranging from bare to oiled or bright, enhancing usability in distinct applications and ensuring optimal performance.

FAQs of EN 10294-1 Grade E355 Pipes:

Q: How are EN 10294-1 Grade E355 pipes manufactured?

A: These pipes are produced using hot finished or cold drawn seamless methods, followed by heat treatment such as normalization or as-rolled processing. This approach ensures enhanced mechanical strength and consistent material quality suited for demanding engineering tasks.Q: What applications are EN 10294-1 Grade E355 pipes suitable for?

A: E355 pipes are widely used in general engineering, CNC machining, structural, and mechanical applications due to their excellent machinability, dimensional accuracy, and robust mechanical properties.Q: When should I request specific inspections or test certificates for these pipes?

A: If your project requires additional quality assurance, you may request Ultrasonic or Eddy Current inspections. Test certificates are available as per EN 10204 3.1 or 3.2 upon order, ensuring traceability and compliance with technical specifications.Q: Where can EN 10294-1 Grade E355 pipes be sourced?

A: These pipes are manufactured and exported worldwide by certified manufacturers, suppliers, traders, and exporters, particularly from India, ensuring global availability for various industry needs.Q: What are the benefits of using EN 10294-1 Grade E355 pipes?

A: The advantages include high yield and tensile strength, good machinability, customizable dimensions and finishes, strict adherence to international standards, and full certification options, contributing to efficient and reliable engineering performance.Q: How can I customize these pipes for my project requirements?

A: Customers can specify dimensions such as diameter, wall thickness (up to 80 mm), length (standard or custom), end types, surface finish, and marking requirements to meet precise application needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in EN Standards Pipe Category

EN 10294-1 Grade E315 Pipes

Usage : Machining, Mechanical Engineering

Material Grade : E315

Standard : Other, EN 102941

Material : Other , Alloy Steel

Surface Treatment : Other, Black Painted / Bare / Oiled

Connection : Other, Plain/Beveled Ends

EN 10210-1 Grade S355JOH Pipes

Usage : Structural and Mechanical Applications

Material Grade : S355JOH

Standard : Other, EN 102101, EN 102191

Material : Carbon Steel

Surface Treatment : Other, Black Painted, Galvanized, Bare

Connection : Other, Plain End, Beveled End, Threaded

EN 10210 S355J2H Pipes

Usage : Structural, Construction, Machinery, General Engineering

Material Grade : S355J2H

Standard : Other, EN 102101, EN 102102

Material : Carbon Steel

Surface Treatment : Other, Black Painted, Bare, Oil Coated, Galvanized

Connection : Other, Plain End, Beveled End

EN 10294-1 Grade E355K2 Pipes

Usage : Machining, Mechanical engineering, Hydraulic cylinder applications

Material Grade : E355K2

Standard : Other, EN 102941

Material : Carbon Steel

Surface Treatment : Other, Black Painted, Oiled, or as requested

Connection : Other, Plain End / Beveled End

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese