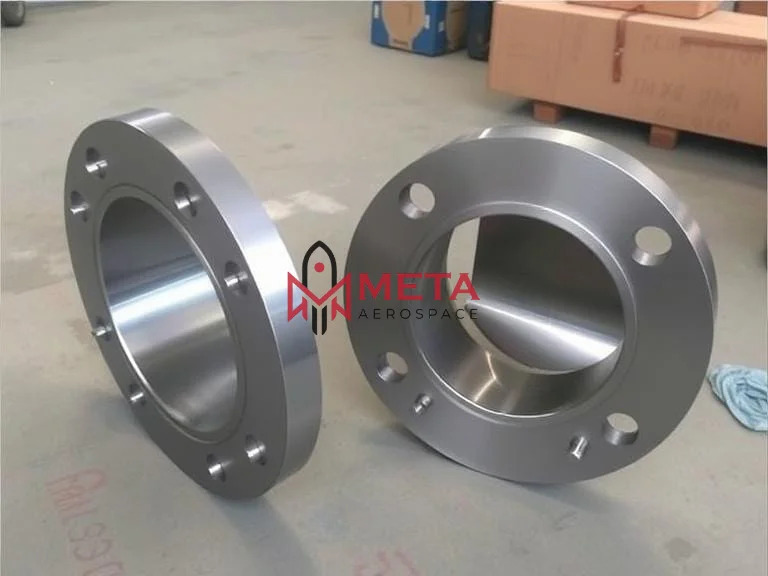

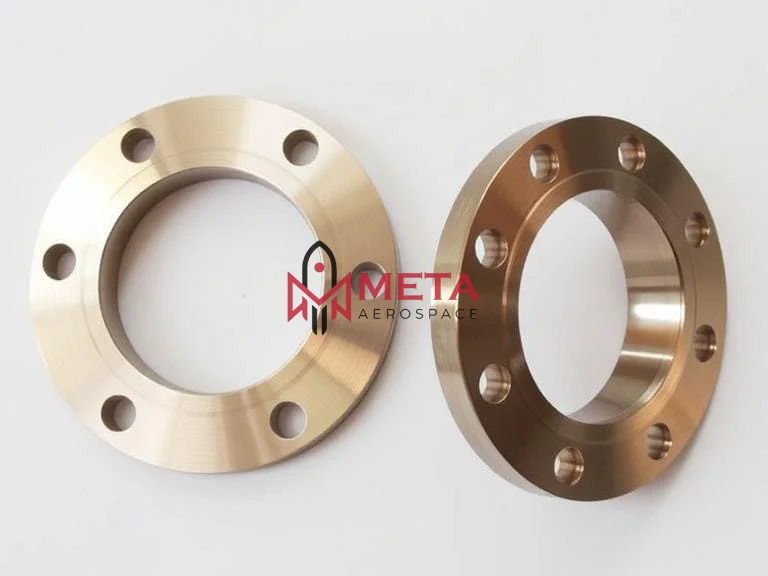

Hastelloy C2000 Flanges

Hastelloy C2000 Flanges Specification

- Feature

- Corrosion Resistant, High Strength, Excellent Fabricability

- Grade

- C2000

- Dimension (L*W*H)

- As per requirement / standard specification

- Application

- Chemical Processing, Petrochemical, Offshore, Power Generation, Pharmaceutical Industries

- Purity

- Nickel-based alloy with high chromium, molybdenum, and copper content

- Product Type

- Flange

- Material

- Hastelloy C2000 (UNS N06200)

- Standard

- ASTM B564 / ASME SB564

- Shape

- Round

- Surface

- Bright, Polished, Shot Blasted

- Connection

- Welded, Threaded, Slip On, Blind, Lap Joint, Socket Weld, Orifice

- Technics

- Forged

- Pressure

- Class 150, 300, 600, 900, 1500, 2500 LBS

- Size

- 1/2 to 48 (DN15 to DN1200)

- Color

- Metallic Silver

- Packing

- Wooden Cases, Pallets or as required

- Face Type

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Melting Point

- 13201380C

- Elongation

- 45% min

- Hardness

- RB 88 max

- Tensile Strength

- 690 MPa min

- Manufacturer Test Certificate

- EN 10204 3.1/3.2

- Density

- 8.50 g/cm

- Standards Compatible

- ANSI, DIN, EN, JIS, BS

- Corrosion Resistance

- Excellent resistance to oxidizing and non-oxidizing chemicals, including wet chlorine gas, hypochlorite, and chlorine dioxide environments

- Yield Strength (0.2% Offset)

- 283 MPa min

About Hastelloy C2000 Flanges

What Are Specification Hastelloy C2000 Flanges?

| Specifications | ASTM B564 / ASME SB564 |

|---|---|

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/2NB TO 60NB |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Grade | Hastelloy C2000 Flanges UNS (N06022), DIN (2.4602) |

Equivalent material Of Hastelloy C2000 Flanges?

| STANDARD | UNS | WNR. | AFNOR | EN | JIS |

|---|---|---|---|---|---|

| Hastelloy C2000 | N06022 | 2.4602 | - | NiCr21Mo14W | NW 6022 |

Chemical Composition Of Hastelloy C2000 Flanges?

| Grade | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr | W | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy C2000 | Balance | 0.010 max | 12.5-14.5 | 0.50 max | 0.08 max | 2-6 | 0.02 max | 0.02 max | 2.5 max | 20-22.5 | 2.5-3.5 | 0.35 max |

Mechanical Properties Of Hastelloy C2000 Flanges?

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Hastelloy C2000 | 8.69 g/cm3 | 1399 C (2550 F) | Psi 1,00,000, MPa 690 | Psi 45000, MPa 310 | 45 % |

Superior Corrosion Resistance

Hastelloy C2000 flanges excel in environments with exposure to aggressive chemicals, including both oxidizing and non-oxidizing agents like wet chlorine gas, hypochlorite, and chlorine dioxide. Their compositionrich in chromium, molybdenum, and copperensures long-lasting durability and integrity, even under the harshest conditions encountered in industrial processing and offshore applications.

Versatile Applications and Connection Types

These flanges come in multiple shapes and connections including welded, threaded, slip-on, blind, lap joint, socket weld, and orifice, accommodating a variety of operational needs. Sizes range from 1/2" to 48" (DN15 to DN1200), and pressure classes from 150 to 2500 LBS, allowing installation in diverse chemical, petrochemical, and power generation systems.

Certified Quality and Reliable Packing

Manufactured to ASTM B564 / ASME SB564 standards, each flange comes with an EN 10204 3.1/3.2 Manufacturer Test Certificate for quality assurance. Careful packing in wooden cases or pallets, per customer requirement, protects the product during transit and storage, ensuring flanges arrive in optimal condition for immediate use.

FAQs of Hastelloy C2000 Flanges:

Q: How should Hastelloy C2000 flanges be installed in a chemical processing system?

A: Hastelloy C2000 flanges can be installed using various connection types such as welded, threaded, slip-on, or socket weld, depending on the systems design and pressure requirements. It is essential to align the face type (RF, FF, or RTJ) with mating flanges and to follow industry-standard installation procedures to ensure operational integrity.Q: What are the primary benefits of using Hastelloy C2000 flanges in corrosive environments?

A: These flanges offer exceptional resistance to both oxidizing and non-oxidizing chemicals, including wet chlorine gas and hypochlorite. Their robust alloy composition provides high strength, excellent fabricability, and long service life, reducing the risk of failures, leaks, and costly downtime in critical industrial applications.Q: When is it recommended to use Raised Face (RF), Flat Face (FF), or Ring Type Joint (RTJ) face types?

A: The selection of face type depends on the application. Raised Face (RF) flanges are commonly used for their versatility in moderate to high-pressure settings. Flat Face (FF) is preferred when mating with cast iron equipment, while Ring Type Joint (RTJ) is ideal for high-pressure, high-temperature environments requiring optimal sealing.Q: Where can Hastelloy C2000 flanges be effectively utilized?

A: They are widely used in industries like chemical processing, petrochemical, offshore oil and gas, power generation, and pharmaceuticalswhere superior corrosion resistance and mechanical strength are vital. Their versatility in dimension and pressure ratings enables use across varied equipment and piping systems.Q: What process certifications are provided with Hastelloy C2000 flanges?

A: Each flange is accompanied by a Manufacturer Test Certificate as per EN 10204 3.1/3.2, confirming chemical composition, mechanical properties, and compliance with ASTM B564 / ASME SB564 standards, ensuring guarantee of quality and traceability for end-users.Q: How are Hastelloy C2000 flanges packed for export or supply?

A: For protection during shipping and handling, flanges are securely packed in wooden cases, pallets, or as specified by the customer. This practice prevents surface damage, maintains product quality, and provides ease of storage and transportation.Q: What is the typical usage of Hastelloy C2000 flanges in power generation and offshore environments?

A: In these demanding settings, Hastelloy C2000 flanges are used to connect critical piping systems where high corrosion resistance, pressure tolerance, and structural integrity are necessary for safe and continuous operation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hastelloy Flanges Category

Hastelloy C22 Flanges

Technics : Other, Forged

Material : Hastelloy C22

Purity : >99% Nickel Alloy

Surface : Other, Polished

Standard : Other, ASTM, ASME, DIN, EN, ISO, JIS

Grade : Hastelloy C22 (UNS N06022)

Hastelloy C276 Flanges

Technics : Other, Forged, Casting

Material : Hastelloy C276 (UNS N10276)

Purity : >99% Nickel Content

Surface : Other, Bright, Machined, Smooth Finish, Rust Proof Oil Coating

Standard : Other, ANSI B16.5, ASTM B564, ASME SB564, DIN, EN, JIS, BS, GB

Grade : C276

Hastelloy Round Flanges

Technics : Hot Rolled

Material : Stainless Steel

Purity : 8099%

Surface : Galvanized

Standard : ANSI

Grade : Multple Grades Available

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese