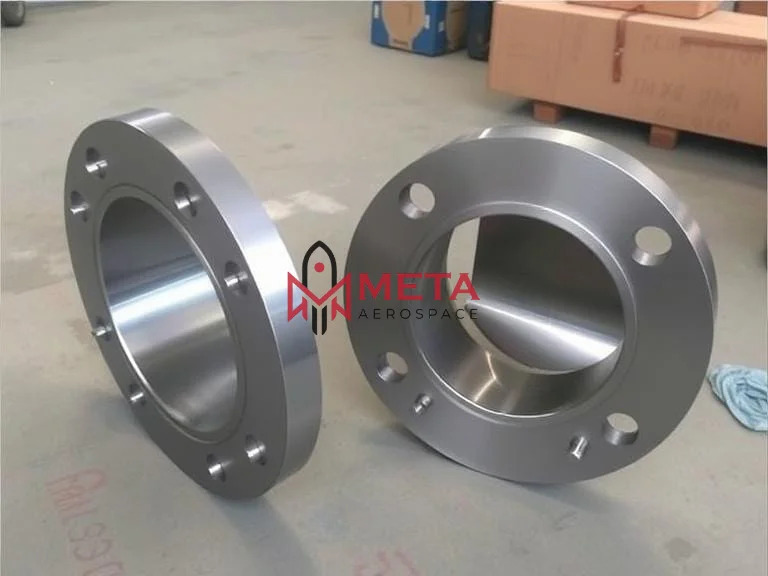

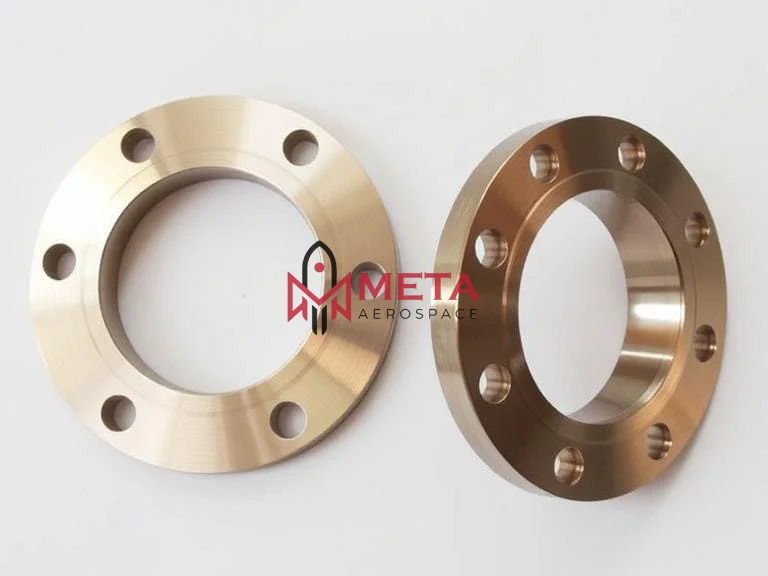

Hastelloy C22 Flanges

Hastelloy C22 Flanges Specification

- Feature

- Corrosion Resistant, High Strength, Durable, Excellent Weldability

- Application

- Chemical Processing, Petrochemicals, Oil & Gas, Pharmaceuticals, Power Generation, Marine Industries

- Purity

- >99% Nickel Alloy

- Dimension (L*W*H)

- As per customer requirement or industry standard

- Grade

- Hastelloy C22 (UNS N06022)

- Product Type

- Flanges

- Material

- Hastelloy C22

- Standard

- ASTM, ASME, DIN, EN, ISO, JIS

- Shape

- Round

- Surface

- Polished

- Connection

- Welded, Threaded, Slip-On, Blind, Socket Weld, Lap Joint, Orifice, Spectacle Blind, Ring Type Joint (RTJ)

- Technics

- Forged

- Pressure

- 150 lbs, 300 lbs, 600 lbs, 900 lbs, 1500 lbs, 2500 lbs

- Size

- 1/2 NB to 24 NB (or custom sizes as per requirement)

- Color

- Silver

- Manufacturing Method

- Hot Forged & Machined

- Hardness

- Rockwell B90 max

- Density

- 8.69 g/cm

- Elongation

- 45% min

- Tensile Strength

- 690 MPa min

- Corrosion Resistance

- Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking

- Standards Followed

- ANSI B16.5, B16.47, MSS-SP-44

- Temperature Range

- -196C to 870C

- End Connections

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Finish

- Smooth, Rust-proof, Oil Coated

- Melting Point

- 13991433C (25502610F)

- Weldability

- Good

About Hastelloy C22 Flanges

What Are Specification Hastelloy C22 Flanges?

| Specifications | ASTM B564 / ASME SB564 |

|---|---|

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/2NB TO 60NB |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Grade | Hastelloy C22 Flanges UNS (N06022), DIN (2.4602) |

Equivalent material Of Hastelloy C22 Flanges?

| STANDARD | UNS | WNR. | AFNOR | EN | JIS |

|---|---|---|---|---|---|

| Hastelloy C22 | N06022 | 2.4602 | - | NiCr21Mo14W | NW 6022 |

Chemical Composition Of Hastelloy C22 Flanges?

| Grade | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr | W | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy C22 | Balance | 0.010 max | 12.5-14.5 | 0.50 max | 0.08 max | 2-6 | 0.02 max | 0.02 max | 2.5 max | 20-22.5 | 2.5-3.5 | 0.35 max |

Mechanical Properties Of Hastelloy C22 Flanges?

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Hastelloy C22 | 8.69 g/cm3 | 1399 C (2550 F) | Psi 1,00,000, MPa 690 | Psi 45000, MPa 310 | 45 % |

Exceptional Corrosion Resistance

Hastelloy C22 Flanges provide outstanding protection against pitting, crevice corrosion, and stress corrosion cracking. Their superior resistance makes them ideal for corrosive processing environments, outperforming many conventional alloys and ensuring long-lasting, maintenance-friendly service life.

Precision Engineering and Quality Standards

Each flange is hot forged and precision-machined, adhering to globally recognized standards such as ANSI B16.5, ASTM, and JIS. The result is a uniform, high-strength product available in a range of sizes, grades, and connection types to suit diverse industry requirements.

FAQs of Hastelloy C22 Flanges:

Q: How are Hastelloy C22 Flanges manufactured?

A: These flanges are produced using hot forging and machining, which imparts high strength and ensures precision dimensions. Hot forging enhances their mechanical properties, while machining provides a smooth, polished surface that is rust-proof and oil coated.Q: What benefits do Hastelloy C22 Flanges offer in chemical processing applications?

A: Hastelloy C22 Flanges stand out for their excellent resistance to pitting, crevice corrosion, and stress corrosion crackingmaking them ideal for harsh chemical environments. Their durability, high strength, and purity ensure longevity and reliability under aggressive process conditions.Q: Where can Hastelloy C22 Flanges be used effectively?

A: These flanges are commonly utilized in chemical processing, petrochemical plants, oil & gas installations, pharmaceuticals, power generation, and marine industries, where superior corrosion resistance and reliable mechanical performance are crucial.Q: What end connection types are available for these flanges?

A: Hastelloy C22 Flanges come with several end connection options, including Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), Welded, Threaded, Slip-On, Blind, Socket Weld, Lap Joint, Orifice, and Spectacle Blind, ensuring compatibility with various systems.Q: When should you choose Hastelloy C22 Flanges over other alloy flanges?

A: Select Hastelloy C22 Flanges when applications demand superior resistance to aggressive chemicals, wide temperature ranges (-196C to 870C), and robust mechanical properties. They are especially suitable for environments involving extreme corrosion and operational pressures up to 2500 lbs.Q: What standards do Hastelloy C22 Flanges adhere to?

A: These flanges comply with multiple international standards, including ANSI B16.5, B16.47, MSS-SP-44, ASTM, ASME, DIN, EN, ISO, and JIS, ensuring their suitability for global industrial use and project specifications.Q: How does the smooth, polished finish benefit the flanges performance?

A: A polished finish reduces the risk of contamination and enhances corrosion resistance. This smooth surface also facilitates easier maintenance and cleaning, which is essential in industries like pharmaceuticals and food processing.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hastelloy Flanges Category

Hastelloy C2000 Flanges

Material : Hastelloy C2000 (UNS N06200)

Purity : Nickelbased alloy with high chromium, molybdenum, and copper content

Size : 1/2 to 48 (DN15 to DN1200)

Grade : C2000

Standard : Other, ASTM B564 / ASME SB564

Technics : Other, Forged

Hastelloy C276 Flanges

Material : Hastelloy C276 (UNS N10276)

Purity : >99% Nickel Content

Size : 1/2 to 24 (DN15 to DN600)

Grade : C276

Standard : Other, ANSI B16.5, ASTM B564, ASME SB564, DIN, EN, JIS, BS, GB

Technics : Other, Forged, Casting

Hastelloy Round Flanges

Material : Stainless Steel

Purity : 8099%

Size : Various Sizes Available

Grade : Multple Grades Available

Standard : ANSI

Technics : Hot Rolled

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese