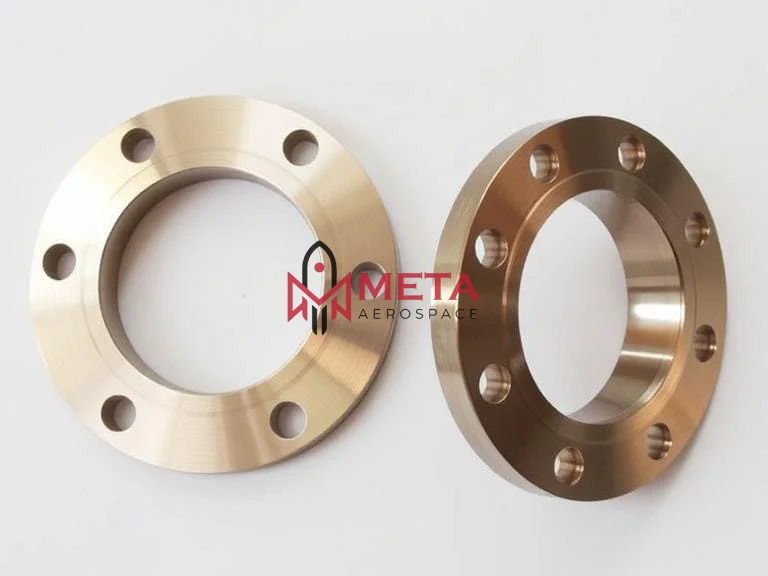

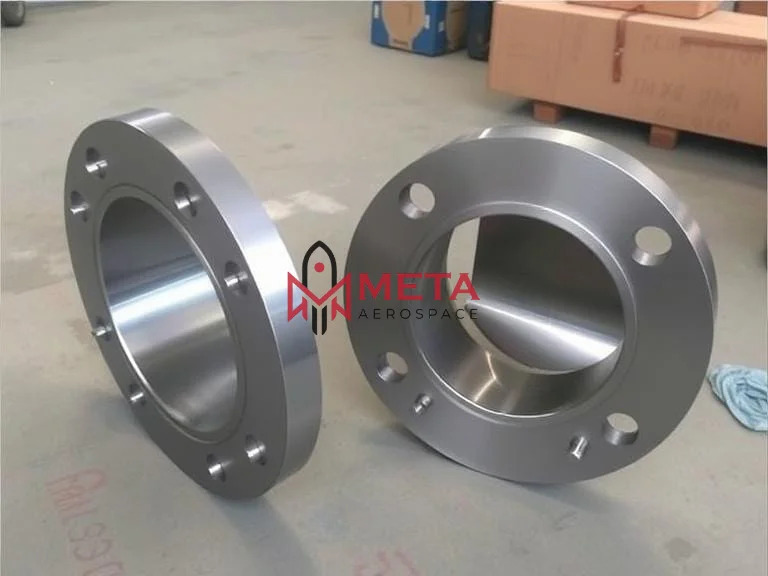

Hastelloy C276 Flanges

Hastelloy C276 Flanges Specification

- Application

- Oil & Gas Industry, Chemical Processing, Petrochemical, Power Plant, Marine, Pharmaceutical, Pulp & Paper

- Dimension (L*W*H)

- As per standard or customer requirement

- Grade

- C276

- Feature

- Corrosion Resistant, High Strength, Excellent Weldability, Non-magnetic

- Purity

- >99% Nickel Content

- Product Type

- Flange

- Material

- Hastelloy C276 (UNS N10276)

- Standard

- ANSI B16.5, ASTM B564, ASME SB564, DIN, EN, JIS, BS, GB

- Shape

- Round

- Surface

- Bright, Machined, Smooth Finish, Rust Proof Oil Coating

- Connection

- Welded, Threaded, Slip On, Blind, Socket Weld, Lap Joint, Orifice

- Technics

- Forged, Casting

- Pressure

- 150# to 2500# (PN 2.5 to PN 400)

- Size

- 1/2 to 24 (DN15 to DN600)

- Color

- Silver, Metallic Grey

- Tensile Strength

- 690 MPa (min)

- Service Temperature

- Upto 1040C

- Testing

- Ultrasonic, PMI, Radiography, Hydrostatic

- Elongation

- 40% (min)

- Corrosion Resistance

- Superior resistance to pitting, crevice corrosion, and stress corrosion cracking in a wide range of chemical environments

- Density

- 8.89 g/cm

- Packaging

- Wooden Boxes, Bubble Wrap, Seaworthy Packing

- End Finish

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- Yield Strength

- 283 MPa (min)

- Hardness

- Rockwell B89 (max)

- Standards Compliance

- NACE MR0175/ISO 15156 compatible

- Melting Point

- 1325C - 1370C

About Hastelloy C276 Flanges

What Are Specification Hastelloy C276 Flanges?

| Specifications | ASTM B564 / ASME SB564 |

|---|---|

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Size | 1/2NB TO 60NB |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Grade | Hastelloy C276 Flanges UNS (N06022), DIN (2.4602) |

Equivalent material Of Hastelloy C276 Flanges?

| STANDARD | UNS | WNR. | AFNOR | EN | JIS |

|---|---|---|---|---|---|

| Hastelloy C276 | N06022 | 2.4602 | - | NiCr21Mo14W | NW 6022 |

Chemical Composition Of Hastelloy C276 Flanges?

| Grade | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr | W | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy C276 | Balance | 0.010 max | 12.5-14.5 | 0.50 max | 0.08 max | 2-6 | 0.02 max | 0.02 max | 2.5 max | 20-22.5 | 2.5-3.5 | 0.35 max |

Mechanical Properties Of Hastelloy C276 Flanges?

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Hastelloy C276 | 8.69 g/cm3 | 1399 C (2550 F) | Psi 1,00,000, MPa 690 | Psi 45000, MPa 310 | 45 % |

Unmatched Corrosion Resistance

Hastelloy C276 Flanges are specifically engineered for resistance against pitting, crevice corrosion, and stress corrosion cracking, even in the harshest chemical environments. This makes them the preferred choice for industries such as oil & gas, chemical processing, and marine applications where long-term reliability is essential.

Global Compliance and Quality Assurance

Manufactured in accordance with respected international standards, including ANSI, ASTM, ASME, DIN, EN, and others, our Hastelloy C276 flanges guarantee consistent quality and precise performance. Each flange is subjected to ultrasonic, PMI, hydrostatic, and radiography tests to ensure their integrity and fitness for demanding applications.

Versatile Design and Broad Usability

Offered in numerous shapes, sizes, and pressure classes, Hastelloy C276 flanges support various connection types such as welded, threaded, slip-on, and blind. Their adaptability and robust construction make them suitable for use in petrochemical, power plants, pharmaceutical, and pulp & paper industries.

FAQs of Hastelloy C276 Flanges:

Q: How does the corrosion resistance of Hastelloy C276 flanges benefit industrial operations?

A: Hastelloy C276 flanges provide exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking, even when exposed to aggressive chemicals. This ensures prolonged service life, reduced maintenance, and increased safety for installations in challenging environments such as chemical processing and marine sectors.Q: What testing procedures are used to ensure the quality of these flanges?

A: Every Hastelloy C276 flange undergoes comprehensive testing, including ultrasonic, Positive Material Identification (PMI), radiography, and hydrostatic tests. These procedures verify structural integrity, material composition, and pressure-holding capability, guaranteeing dependable performance and compliance with international standards.Q: When should Hastelloy C276 flanges be chosen over other materials?

A: They are ideal for scenarios demanding superior corrosion resistance, high mechanical strength, and excellent weldability, particularly in industries such as oil & gas, petrochemical, and power generation. Applications involving exposure to harsh chemicals, high pressures, and elevated temperatures benefit most from Hastelloy C276.Q: Where are these flanges commonly installed?

A: Hastelloy C276 flanges are widely used in oil & gas pipelines, chemical plants, marine environments, power stations, pharmaceutical production lines, and pulp & paper processing facilities. Their resilience and versatility support diverse industrial needs worldwide.Q: What end finishes and connection types are available for these flanges?

A: Options include Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ), supporting connections such as welded, threaded, slip-on, blind, socket weld, lap joint, and orifice. This adaptability allows integration into various piping systems and custom installations.Q: How are Hastelloy C276 flanges packaged to ensure safe delivery?

A: Each flange is carefully packed using wooden boxes, bubble wrap, and seaworthy materials to safeguard against mechanical damage and corrosion during transit. Rust-proof oil coatings provide an extra layer of protection until installation.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hastelloy Flanges Category

Hastelloy C22 Flanges

Grade : Hastelloy C22 (UNS N06022)

Standard : Other, ASTM, ASME, DIN, EN, ISO, JIS

Size : 1/2 NB to 24 NB (or custom sizes as per requirement)

Technics : Other, Forged

Purity : >99% Nickel Alloy

Surface : Other, Polished

Hastelloy C2000 Flanges

Grade : C2000

Standard : Other, ASTM B564 / ASME SB564

Size : 1/2 to 48 (DN15 to DN1200)

Technics : Other, Forged

Purity : Nickelbased alloy with high chromium, molybdenum, and copper content

Surface : Other, Bright, Polished, Shot Blasted

Hastelloy Round Flanges

Grade : Multple Grades Available

Standard : ANSI

Size : Various Sizes Available

Technics : Hot Rolled

Purity : 8099%

Surface : Galvanized

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese