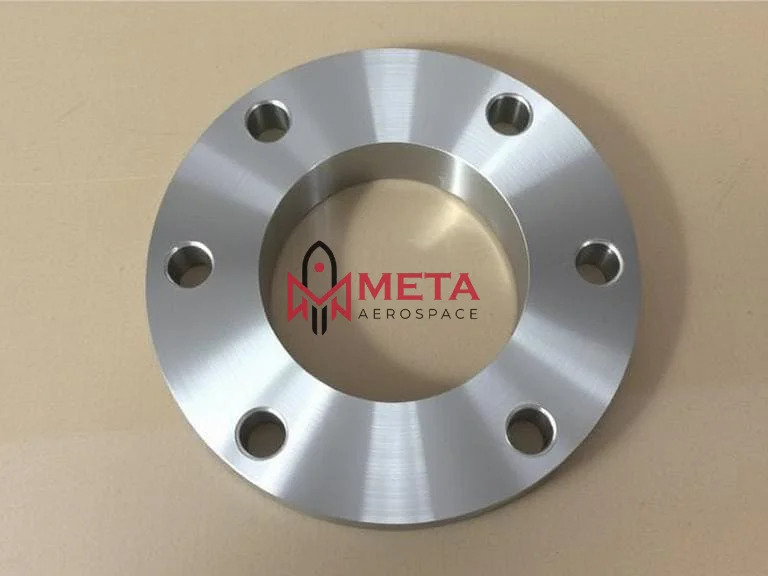

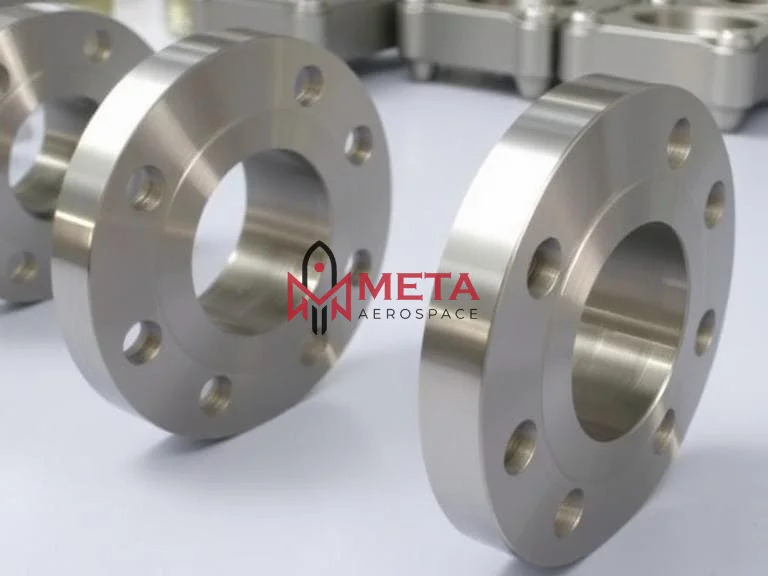

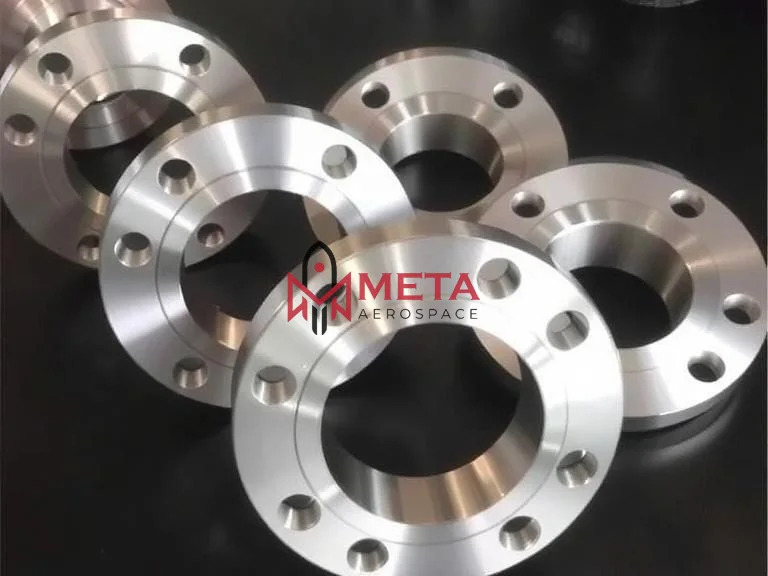

Inconel 718 Flanges

Inconel 718 Flanges Specification

- Application

- Aerospace, Petrochemical, Power Generation, Oil & Gas Industries

- Purity

- >99% Nickel Alloy

- Grade

- Inconel 718 (UNS N07718)

- Dimension (L*W*H)

- As per customer requirement

- Feature

- Corrosion Resistant, High Strength, Excellent Weldability

- Product Type

- Flanges

- Material

- Inconel 718

- Standard

- ASTM B564, ASME SB564

- Shape

- Round, Square, Rectangular

- Surface

- Smooth, Nickel Plated

- Connection

- Welded, Threaded

- Technics

- Forged

- Pressure

- Class 150 to 2500

- Size

- 1/2 to 48

- Color

- Silver Grey

- Density

- 8.19 g/cm

- Elongation

- 12%

- Tensile Strength

- 1260 MPa

- Packaging

- Wooden Cases or Pallets

- Standards Compliance

- NACE MR0175, ISO, DIN

- Yield Strength

- 1035 MPa

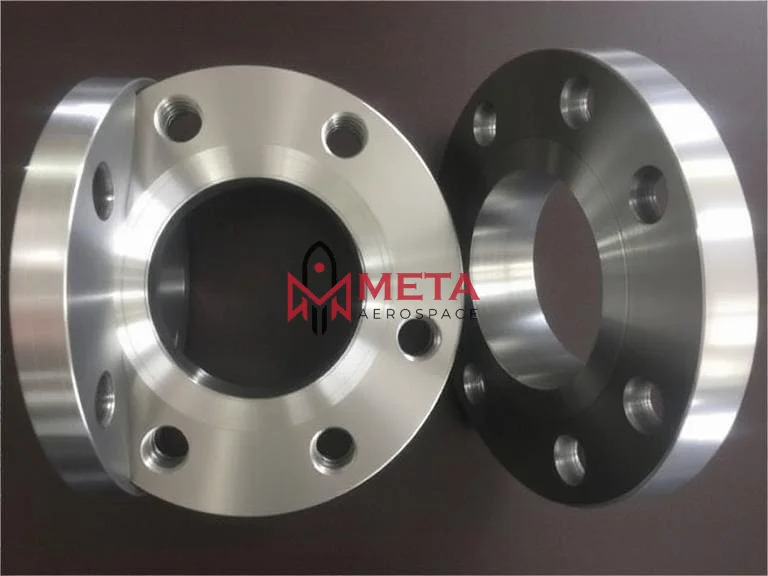

- Face Type

- Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

- End Type

- Butt Weld, Socket Weld, Threaded

- Hardness

- Rockwell C35 Max

- Temperature Range

- -196C to 700C

About Inconel 718 Flanges

What Are Specification Inconel 718 Flanges?

| Standards | GOST Flange, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092, BS, BS4504, BS 10, EN-1092, DIN, ANSI, ASME, DIN, MSS S44, ISO70051, ANSI/ASME B16.5, ASME/ANSI B16.5/16.36/16.47A/16.47B, B16.47 Series A & B, B16.48, EN |

|---|---|

| Pressure Rating ANSI | Class 1500, Class 150, Class 900, Class 2500, Class 300, Class 600, |

| Pressure Calculation in DIN | 10Bar, 16Bar, 25Bar, 40Bar, 6Bar, / PN16, PN64, PN40, PN25, PN10, PN6 |

| JIS | 16 K, 20 K, 5K, 10 K, 40 K, 63 K, 30 K, |

| UNI | 10Bar 16Bar 6Bar 25Bar 40Bar |

| EN | 6Bar 25Bar 40Bar 10Bar 16Bar |

| Most common Types | Threaded / Screwed / Forged / Plate |

| Production technique | Forged, Heat treated and machined |

| Shapes and Types we produce | Large Male-Female (LMF), Ring Type Joint (RTJ), Flat Face (FF), Small Tongue, Small Male-Female (SMF),Raised Face (RF), Large Tongue & Groove, Groove, Lap-Joint Face (LJF) |

| Test | Direct-reading Spectrograph, Magnetic particle detector, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector |

| Equipment | Pushing Machine, Press machine, Bending machine, Sand-blasting machine, electric bevelling machine etc |

Equivalent material Of Inconel 718 Flanges?

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Inconel 718 | 2.4668 | N07718 | NCF 718 |

Chemical Composition Of Inconel 718 Flanges?

| Grade | C | Mn | Si | Cr | S | Fe | Mo | Ni | Cu |

|---|---|---|---|---|---|---|---|---|---|

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 17.021.0 | 0.15 max | 50.0-55.0 min | 0.30 max |

Mechanical Properties Of Inconel 718 Flanges?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.2 g/cm3 | 1.350 C (2460 F) | Psi 1,35,000 , MPa 930 | Psi 75,000 , MPa 482 | 45 % |

Outstanding Mechanical Properties

Inconel 718 flanges excel under extreme conditions, offering a yield strength 1035 MPa and tensile strength of 1260 MPa. Their elongation ( 12%) and maximum hardness of Rockwell C35 ensure they accommodate stress and deformation, making them ideal for high-pressure and high-temperature environments.

Flexible Design and Application

These flanges are available in a wide size range (1/2 inch to 48 inches), different shapes, and custom dimensions per client requirements. Their face types (RF, FF, RTJ) allow use in versatile settings, while connections can be welded or threaded, enabling integration in complex systems.

Strict Compliance & Superior Finish

Compliant with global standards (NACE MR0175, ISO, DIN, ASTM B564, ASME SB564), each flange is manufactured using advanced forging techniques and finished with a smooth, nickel-plated surface. Packaging in wooden cases or pallets assures integrity during shipping.

FAQs of Inconel 718 Flanges:

Q: How are Inconel 718 flanges manufactured and finished?

A: Inconel 718 flanges are produced via forginga process that enhances grain structure and mechanical strength. After shaping, they receive a smooth, nickel-plated surface finish to protect against corrosion and wear. Strict quality controls are applied to meet ASTM B564 and ASME SB564 standards.Q: What applications are best suited for these flanges?

A: These flanges are ideal for aerospace, petrochemical, power generation, and oil & gas industries. Their excellent weldability, high strength, and corrosion resistance make them suitable for both high-pressure and high-temperature environments where reliable performance is critical.Q: When should I choose a specific face type (RF, FF, RTJ) for my application?

A: Select the face type based on the sealing and pressure needs of your system. Raised Face (RF) is common in most pressure classes, Flat Face (FF) is preferred where the mating flange is also flat, and Ring Type Joint (RTJ) is used for high-pressure, high-temperature applications demanding superior sealing.Q: Where are these Inconel 718 flanges typically installed?

A: They are commonly installed in pipelines, vessels, valves, and process equipment within power plants, refineries, chemical facilities, and aerospace assemblies. Their corrosion resistance and mechanical properties are crucial in such harsh environments.Q: What are the advantages of using Inconel 718 material?

A: Inconel 718 offers outstanding corrosion resistance, excellent mechanical strength, and stability at temperatures from -196C to 700C. Its high purity and nickel content (>99%) ensure prolonged service life and reliability in aggressive media and extreme conditions.Q: How does compliance with standards benefit the user?

A: Compliance with international standards like NACE MR0175, ISO, and DIN ensures the flanges meet global safety, reliability, and performance requirements. This guarantees compatibility, traceability, and assures customers of consistent, high-quality products.Q: What is the packaging process for these flanges?

A: After production and final inspection, flanges are securely packed in wooden cases or on pallets. This protects them from physical damage and environmental exposure during storage and transportation, preserving their quality and finish.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inconel Flanges Category

Inconel 600 Flanges

Technics : Other, Forged

Standard : Other, ASTM B564, ASME SB564, DIN, EN, JIS, BS, GB, GOST

Purity : Nickel 72%

Surface : Other, Polished / Mill Finish

Size : 1/2 to 48 (DN15~DN1200)

Grade : Inconel 600 / UNS N06600

Inconel 601 Flanges

Technics : Other, Forged / Cast

Standard : Other, ASTM, ASME, DIN, EN, JIS, BS, UNI, GOST

Purity : High Alloy Content

Surface : Other, Bright, Polished, Black, CNC Machined

Size : 1/2 to 48 (DN15 to DN1200)

Grade : Inconel 601 (UNS N06601)

Inconel 625 Flanges

Technics : Other, Forged, Machined

Standard : Other, ASTM B564, ASME SB564, DIN, EN, JIS, GB, IS, BS

Purity : Nickel content approximately 58% minimum

Surface : Other, Bright, Black, Polished, Rough

Size : 1/2 inch to 48 inch (DN15 to DN1200)

Grade : UNS N06625, Alloy 625

Inconel Round Flanges

Technics : Hot Rolled

Standard : ANSI

Purity : 8099%

Surface : Galvanized

Size : Various Sizes Available

Grade : Multple Grades Available

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese