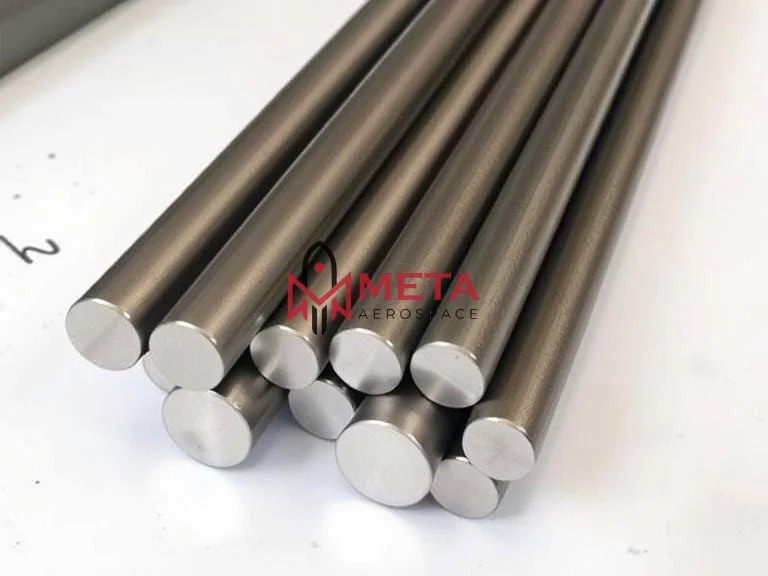

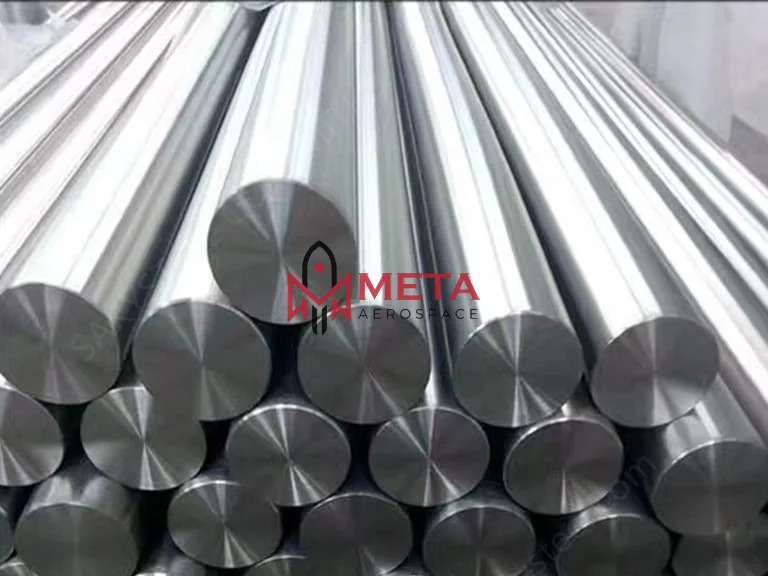

Maraging Steel C350 Round Bar

Maraging Steel C350 Round Bar Specification

- Diameter

- 4 mm to 300 mm

- Technique

- Hot Rolled, Cold Drawn

- Finish

- Bright, Black, Polished

- Specific Use

- High-strength structural applications

- Grade

- C350

- Standard

- ASTM A579, AMS 6512

- Material

- Maraging Steel C350

- Tolerance

- H9, H10, or as required

- Length

- 1 to 6 meters (custom lengths available)

- Type

- Round Bar

- Processing

- Aged and Solution Annealed

- Application

- Aerospace, Tooling, Engineering Components, and Defense Equipment

- Weldability

- Good (Welded using conventional methods)

- Hardness

- 45-50 HRC (after heat treatment)

- Yield Strength

- up to 2,100 MPa (after aging)

- Ultimate Tensile Strength

- up to 2,400 MPa

- Corrosion Resistance

- Excellent

- Elongation

- 8-11% (in 50 mm)

- Heat Treatment

- Solution Annealed at 820C, Aged at 480C

- Density

- 8.1 g/cm

- Machinability

- Good in aged condition

About Maraging Steel C350 Round Bar

What Are Specification Maraging Steel C350 Round Bar?

| Standard | AMS 6514, AMS 6515, MIL-S-46850, ASTM A538 |

|---|---|

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

| Round Bar Size | Diameter: 3-~800mm |

| Flat Bar Size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Square Bar Size | 4 to 100mm |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Rod, Round, Flat Bar, Square, Round Rod, Forging etc. |

Equivalent material Of Maraging Steel C350 Round Bar?

| STANDARD | WERKSTOFF NR. | UNS | GB | BS |

|---|---|---|---|---|

| Maraging 300 | 1.6354 / 1.6358 | K93160 | 1Cr18Ni9 | S162 |

| Vascomax 350 | 1.6356 | K93120 | 1Cr18Ni9 | S162 |

Chemical Composition Of Maraging Steel C350 Round Bar?

| Weight% | Ni | Co | Mn | Si | C | B | P | S | Al | Mo | Ti | Zr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Maraging 300 | 18.0-19.0 | 8.0-9.5 | 0.10 max | 0.10 max | 0.03 max | - | 0.010 max | 0.010 max | 0.05-0.15 | 4.6-5.2 | 0.55-0.80 | - |

| Maraging 350 | 18.50 | 12.0 | 0.10 max | 0.10 max | 0.03 max | 0.003 | 0.01 max | 0.01 max | 0.10 | 4.8 | 1.40 | 0.01 |

Mechanical Properties Of Maraging Steel C350 Round Bar?

| Material | 0.2 % Yield Strength ksi | Ultimate Tensile Strength ksi | Elongation in 4D(%) | Reduction of Area % | Hardness Rc |

|---|---|---|---|---|---|

| Maraging 300, Solution Annealed 1500 F (816C), 1hr, AC | 120 | 150 | 16 | 70 | 30 |

| Solution Annealed Plus Aged 900 F (482C), 3 hrs AC | 280 | 290 | 8 | 40 | 52 |

| Maraging 350 | 330 | 350 | 8 | - | - |

High Strength and Durability

Maraging Steel C350 Round Bars are engineered for high-strength structural applications where durability is vital. After aging and heat treatment, the exceptional yield and tensile strengths ensure reliable performance in challenging environments like aerospace, defense, and engineering sectors. Their robust properties allow them to withstand significant stress without deformation.

Versatile Processing and Customization

These round bars are available in a range of diameters (4 mm to 300 mm) and customizable lengths (1 to 6 meters), providing flexibility for various project requirements. Both hot rolled and cold drawn techniques are employed, ensuring precise tolerance levels (H9, H10, or as specified) and tailored finish options, such as bright, black, or polished surfaces.

FAQs of Maraging Steel C350 Round Bar:

Q: What are the key benefits of using Maraging Steel C350 Round Bar in engineering applications?

A: Maraging Steel C350 Round Bars offer superior yield and tensile strengths (up to 2,100 MPa and 2,400 MPa respectively), excellent corrosion resistance, and good machinability. These properties make them suitable for high-stress environments, prolonging component life and reducing maintenance costs.Q: How is the Maraging Steel C350 Round Bar processed to achieve high strength?

A: The round bars are solution annealed at 820C and then aged at 480C. This heat treatment enhances their hardness (45-50 HRC) and mechanical properties, resulting in high strength and toughness.Q: Which industries typically use Maraging Steel C350 Round Bar?

A: These bars are commonly used in aerospace, tooling, defense equipment, and engineering components owing to their robust mechanical properties and reliability in critical structural applications.Q: What is the typical machinability and weldability of Maraging Steel C350 Round Bar?

A: Maraging Steel C350 exhibits good machinability in its aged condition and can be welded using conventional methods. This makes fabrication and assembly processes straightforward and efficient.Q: When should Maraging Steel C350 Round Bar be chosen over other materials?

A: It should be selected when a combination of high strength, good elongation, excellent corrosion resistance, and reliable hardness is requiredespecially in applications such as structural aerospace parts or defense components.Q: Where can I purchase Maraging Steel C350 Round Bar in India?

A: You can source Maraging Steel C350 Round Bars from reputable exporters, manufacturers, suppliers, and traders across India, who comply with recognized standards like ASTM A579 and AMS 6512.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Other Round Bars Category

Vascomax 350 Round Bar

Processing : Forged

Type : Round Bar

Application : Construction, Engineering, Aerospace, Automotive

Tolerance : +/ 0.05 mm

Material : Vascomax 350

Length : 16 Meter

253 MA [S30815] Round Bar

Processing : Peeled, Turned, Ground

Type : Round Bar

Application : Industrial, Construction, Petrochemical, Oil & Gas, Power Generation, Heat Exchangers

Tolerance : H9, H11, or as specified

Material : 253 MA (UNS S30815) Stainless Steel

Length : 3 meter to 6 meter or as required

Nimonic 90 Round Bar

Processing : Forged, Rolled

Type : Round Bar

Application : Aerospace, Gas Turbine Components, Oil & Gas, Power Generation

Tolerance : H9, H11, H13, as per requirement

Material : Nimonic 90

Length : 100 mm to 6000 mm

A286 Round Bar

Processing : Annealed, Solution Treated

Type : Round Bar

Application : Aerospace, Turbine Engines, High Temperature Fasteners, Gas Turbines

Tolerance : +/ 0.01mm

Material : A286 (IronNickelChromium Alloy)

Length : Custom Cut, up to 6 meters

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

![253 MA [S30815] Round Bar](https://cpimg.tistatic.com/11449080/b/4/253-MA-S30815-Round-Bar..webp)

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese