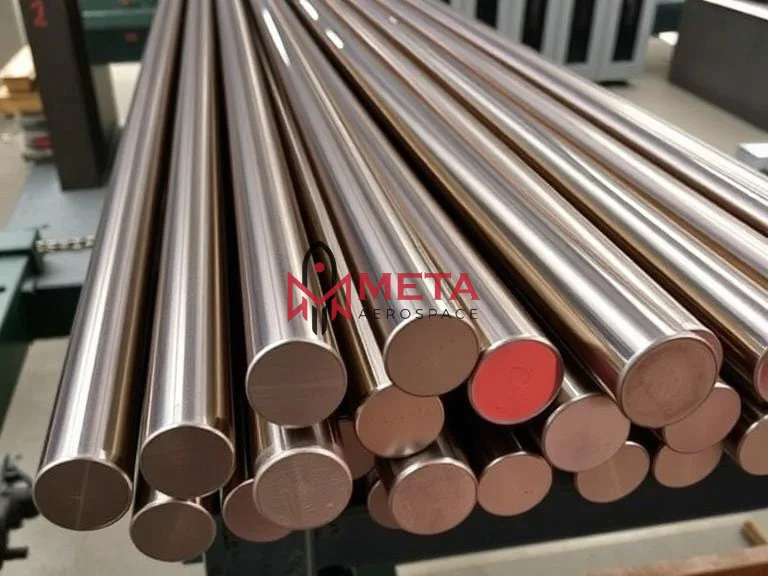

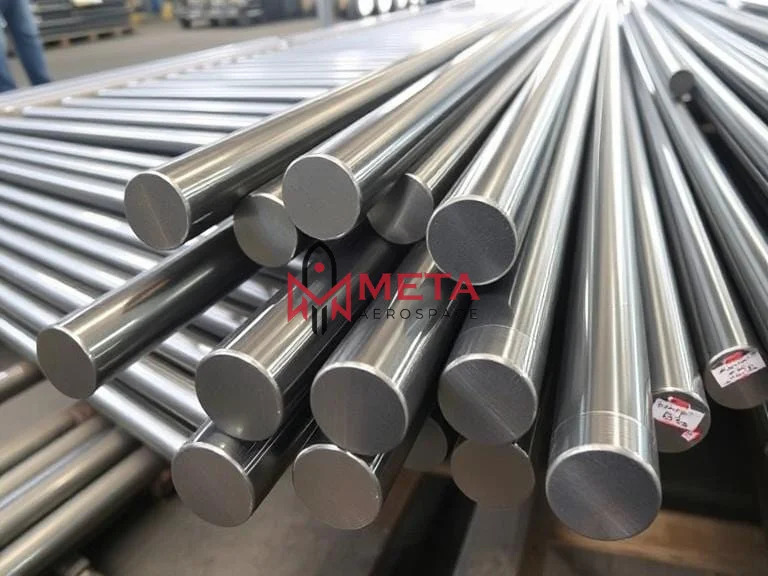

Nimonic 90 Round Bar

Nimonic 90 Round Bar Specification

- Diameter

- 6 mm to 300 mm

- Processing

- Forged, Rolled

- Standard

- ASTM, ASME, AMS 5829

- Type

- Round Bar

- Length

- 100 mm to 6000 mm

- Grade

- Nimonic Alloy 90

- Material

- Nimonic 90

- Finish

- Bright, Black, Polished

- Specific Use

- Manufacturing components exposed to high temperatures and stress

- Tolerance

- H9, H11, H13, as per requirement

- Application

- Aerospace, Gas Turbine Components, Oil & Gas, Power Generation

- Technique

- Hot Rolled / Cold Drawn

- Heat Treatment

- Solution Treated and Aged

- Elongation

- 15% min

- Density

- 8.18 g/cm

- Tensile Strength

- Up to 1100 MPa

- Surface

- Smooth

- Hardness

- 220-250 HB

- Condition

- Solution Annealed

- Melting Point

- 1320C - 1380C

- Yield Strength

- 750 MPa min

- Corrosion Resistance

- Excellent resistance to oxidation and corrosion at high temperatures

- Machinability

- Good with recommended tools

About Nimonic 90 Round Bar

What Are Specification Nimonic 90 Round Bar?

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

|---|---|

| Hex Bar Size | 2-100mm A/F |

| Round Bar Size | Diameter: 3-~800mm |

| Flat Bar Size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Angle Bar Size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Square Bar Size | 4 to 100mm |

| Channel Bar | 80 x 40mm to 150 x 90mm section; 5.0 to 6.0mm thickness |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Threaded Bar Billet Size | 1/2 to 495mm Diameter |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Rod, Round, Channel Bar, T-Bar, Flat Bar, Precision Ground Bar, Blocks, Square, Rings, Round Rod, Triangle, Hollow, Rectangle, Threaded, Hex (A/F), Profiles, Half Round Bar, Ingot, Billet, I/H Bar, Forging etc. |

Equivalent material Of Nimonic 90 Round Bar?

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Alloy 90 | 2.4632 | N07090 |

Chemical Composition Of Nimonic 90 Round Bar?

| Grade | Ni | Cr | Co | Ti | Al | C | Si | Cu | Fe | Mn | B | S | Zr | Pb |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Alloy 90 | Bal | 18-21 | 15-21 | 2-3 | 1-2 | 0.2 max | 1.0 max | 0.2 max | 1.5 max | 1.0 max | 0.02 max | 0.015 max | 0.15 max | 0.0020 max |

Mechanical Properties Of Nimonic 90 Round Bar?

| Material Extruded Bar | Temperature C | Yield Strength 0.2 % (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness HV |

|---|---|---|---|---|---|

| Nimonic 90 bar Solution Treated (BS HR2) | RT | - | - | - | 295 max |

| Nimonic 90 bar Precipition Treated (BS HR2) | RT | 695 min | 1080 min | 20 min | 310 min |

| Nimonic 90 Bar Precipitation Treated (BS HR2) | 500 | 672 (typical) | 1038 (typical) | 31 | - |

Superior Thermal and Mechanical Properties

Nimonic Alloy 90 Round Bars are engineered to endure challenging operating conditions involving high temperatures and mechanical stress. Their robust tensile and yield strengths, along with outstanding hardness and elongation, ensure sustained performance in critical sectors. The solution-annealed and aged treatment enhances their stability, while their excellent corrosion and oxidation resistance guarantees longevity.

Precision Engineering and Versatile Applications

Manufactured to strict standards like ASTM, ASME, and AMS 5829, Nimonic 90 Round Bars come in various diameters and lengths, with tolerance options H9, H11, and H13. Their smooth, bright, black, or polished finishes, and efficient machinability, make them suitable for aerospace, gas turbine, oil & gas, and power generation industriesespecially where components face high stress and thermal exposure.

FAQs of Nimonic 90 Round Bar:

Q: How is Nimonic 90 Round Bar typically processed and finished?

A: Nimonic 90 Round Bars are manufactured through hot rolling or cold drawing and then undergo solution treatment and ageing to optimize their mechanical properties. Finishes can range from bright and polished to black, with surfaces achieving high smoothness as per application requirements.Q: What benefits does using Nimonic 90 Round Bar offer for high-temperature environments?

A: This alloy offers exceptional resistance to oxidation and corrosion even at high temperatures, retaining its strength and stability. As a result, it is ideal for components exposed to significant thermal and mechanical stress, ensuring extended component life and reliable performance.Q: When should I choose Nimonic 90 Round Bar over other superalloys?

A: Nimonic 90 is preferred when your application involves prolonged exposure to extreme heat and stresssuch as in aerospace engines, gas turbines, or power generation. Its combination of strength, ductility, and corrosion resistance outperforms many other alloys under comparable conditions.Q: Where are Nimonic 90 Round Bars typically utilized?

A: These round bars are commonly used in the aerospace industry, gas turbine engine components, oil & gas infrastructures, and power generation plants. Their robust performance makes them indispensable in environments where both reliability and durability are crucial.Q: What is the recommended way to machine Nimonic 90 Round Bar?

A: Although Nimonic 90 offers good machinability, it is best worked with tools specifically designed for high-temperature alloys. Using recommended cutting parameters and lubricants will achieve optimal results and extend tool life.Q: How does the solution annealing and ageing process affect the alloys performance?

A: Solution annealing and subsequent ageing enhance the alloys microstructure, significantly improving its tensile strength, hardness, and resistance to thermal fatigue, making it more reliable for use in high-stress, high-temperature applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Other Round Bars Category

Nimonic 105 Round Bar

Application : Aerospace, Gas Turbines, Power Generation, Heat Treatment, HighTemperature Environments

Technique : Hot Rolled, Forged

Specific Use : Turbine Blades, Shafts, Fasteners, Engine Components

Tolerance : H9, H11, or as specified

Finish : Bright, Polished, Black

Length : 100 mm to 6000 mm

Maraging Steel C300 Round Bar

Application : Aerospace, Tooling, Moulds, Defense, Engineering Components

Technique : Forged / Hot Rolled / Cold Drawn

Specific Use : Precision Components, High Strength Structural Parts

Tolerance : H9, H10, H11 or as per requirement

Finish : Bright, Polished, Black

Length : 100 mm 6000 mm

Sanicro 28 Round Bar

Application : Chemical processing, oil and gas, seawater applications, pollution control, pulp & paper industry

Technique : Hot Rolled / Cold Drawn

Specific Use : Corrosionresistant structural components

Tolerance : H9, H11, K12 or as specified

Finish : Bright, Black, Polished

Length : 2 Meter 6 Meter (Custom Cut Available)

Nimonic 80S Round Bar

Application : Engineering, Construction and Manufacturing

Technique : Hot Rolled / Forged

Specific Use : Aerospace Components, Gas Turbine Parts

Tolerance : H9, H11, H13

Finish : Bright, Black, Polished

Length : As per requirement / Customized

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese