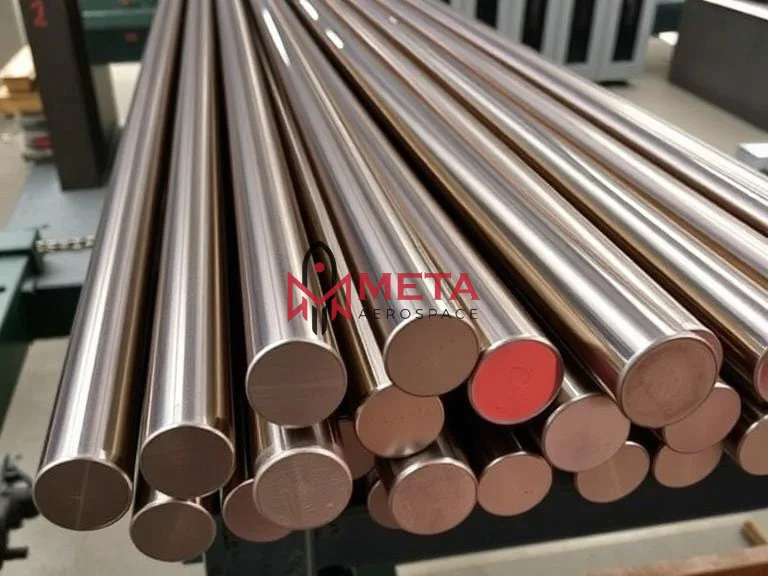

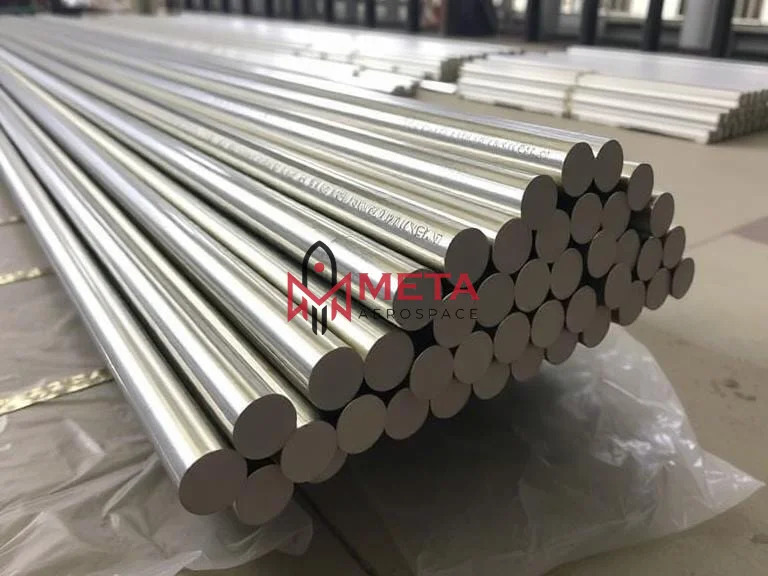

Maraging Steel C300 Round Bar

Maraging Steel C300 Round Bar Specification

- Technique

- Forged / Hot Rolled / Cold Drawn

- Type

- Round Bar

- Tolerance

- H9, H10, H11 or as per requirement

- Grade

- C300 (18Ni (300))

- Finish

- Bright, Polished, Black

- Diameter

- 4 mm - 350 mm

- Application

- Aerospace, Tooling, Moulds, Defense, Engineering Components

- Material

- Maraging Steel

- Length

- 100 mm - 6000 mm

- Specific Use

- Precision Components, High Strength Structural Parts

- Standard

- ASTM A579 / A579M, AMS 6514

- Processing

- Annealed, Solution Treated & Aged

- Form

- Solid Bar

- Surface Condition

- Peeled / Turned / Centerless Ground / Polished

- Density

- 8.0 g/cm

- Hardness

- 48-54 HRC (aged)

- Ultimate Tensile Strength

- ~2050 MPa (min, aged)

- Elongation

- 10-15% (aged)

- Yield Strength

- ~200 ksi (1380 MPa, aged)

- Corrosion Resistance

- Good (not as high as stainless steel)

- Magnetic Properties

- Magnetic

- Heat Treatment

- Solution Annealed at 820C, Aged at 480-500C

About Maraging Steel C300 Round Bar

What Are Specification Maraging Steel C300 Round Bar?

| Standard | AMS 6514, AMS 6515, MIL-S-46850, ASTM A538 |

|---|---|

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

| Round Bar Size | Diameter: 3-~800mm |

| Flat Bar Size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Square Bar Size | 4 to 100mm |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Rod, Round, Flat Bar, Square, Round Rod, Forging etc. |

Equivalent material Of Maraging Steel C300 Round Bar?

| STANDARD | WERKSTOFF NR. | UNS | GB | BS |

|---|---|---|---|---|

| Maraging 300 | 1.6354 / 1.6358 | K93160 | 1Cr18Ni9 | S162 |

| Vascomax 350 | 1.6356 | K93120 | 1Cr18Ni9 | S162 |

Chemical Composition Of Maraging Steel C300 Round Bar?

| Weight% | Ni | Co | Mn | Si | C | B | P | S | Al | Mo | Ti | Zr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Maraging 300 | 18.0-19.0 | 8.0-9.5 | 0.10 max | 0.10 max | 0.03 max | - | 0.010 max | 0.010 max | 0.05-0.15 | 4.6-5.2 | 0.55-0.80 | - |

| Maraging 350 | 18.50 | 12.0 | 0.10 max | 0.10 max | 0.03 max | 0.003 | 0.01 max | 0.01 max | 0.10 | 4.8 | 1.40 | 0.01 |

Mechanical Properties Of Maraging Steel C300 Round Bar?

| Material | 0.2 % Yield Strength ksi | Ultimate Tensile Strength ksi | Elongation in 4D(%) | Reduction of Area % | Hardness Rc |

|---|---|---|---|---|---|

| Maraging 300, Solution Annealed 1500 F (816C), 1hr, AC | 120 | 150 | 16 | 70 | 30 |

| Solution Annealed Plus Aged 900 F (482C), 3 hrs AC | 280 | 290 | 8 | 40 | 52 |

| Maraging 350 | 330 | 350 | 8 | - | - |

Exceptional Mechanical Strength

Maraging Steel C300 Round Bars are recognized for their remarkable yield and tensile strength after proper heat treatment. With ultimate tensile strength exceeding 2050 MPa and yield strength of about 1380 MPa, these bars provide superior performance in high-stress applications, making them preferred for critical aerospace and engineering components.

Superior Dimensional Consistency

Manufactured under rigorous international standards like ASTM A579 and AMS 6514, these round bars offer tight tolerances (H9, H10, H11) and impressive surface finishes ranging from bright and polished to centerless ground. This consistency makes them ideal for precision components requiring dependable mechanical and dimensional integrity.

Tailored for High-Performance Applications

With its reliable properties and adaptability, Maraging Steel C300 Round Bar is primarily employed in industries needing exceptional strength and ductility. Typical applications include aerospace structures, tooling, moulds, defense and engineering components, where superior machine-ability and predictable aging response are essential.

FAQs of Maraging Steel C300 Round Bar:

Q: How is Maraging Steel C300 Round Bar typically used in industry?

A: Maraging Steel C300 Round Bars are extensively used in manufacturing high-strength structural parts, aerospace components, tooling inserts, moulds, and defense parts due to their outstanding mechanical properties and predictable performance after heat treatment.Q: What is the process for heat treating Maraging Steel C300 Round Bar to achieve optimum properties?

A: The round bar is first solution annealed at approximately 820C, which dissolves alloying elements. It is then cooled and aged at 480-500C, resulting in precipitation hardening that enhances both strength and hardness to the desired levels.Q: Where can Maraging Steel C300 Round Bar be sourced in India?

A: This product is available through a network of exporters, manufacturers, suppliers, and traders across India, supplying bars in various sizes, tolerances, and surface finishes as per customer requirements.Q: What are the main benefits of using C300 Maraging Steel in precision components?

A: C300 Maraging Steel features high yield and tensile strength, good ductility, and stable mechanical properties after aging, making it ideal for demanding precision components. Its reliable response to heat treatment ensures consistent performance in critical applications.Q: How does the corrosion resistance of Maraging Steel C300 compare to stainless steel?

A: While Maraging Steel C300 offers good corrosion resistance suitable for most engineering environments, it does not match the corrosion resistance of stainless steels and should be protected or coated in aggressive environments where necessary.Q: What forms and finishes are available for Maraging Steel C300 Round Bars?

A: These round bars are supplied as solid bars in bright, polished, black, centerless ground, or peeled/turned surface conditions, with diameters from 4 mm to 350 mm and lengths up to 6000 mm, tailored to specific engineering needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Other Round Bars Category

Nimonic 105 Round Bar

Length : 100 mm to 6000 mm

Material : Nimonic 105

Application : Aerospace, Gas Turbines, Power Generation, Heat Treatment, HighTemperature Environments

Diameter : 6 mm to 200 mm

Processing : Annealed, Solution Treated

Standard : ASTM, AMS 5822, BS HR 504, DIN 17742

Nimonic 90 Round Bar

Length : 100 mm to 6000 mm

Material : Nimonic 90

Application : Aerospace, Gas Turbine Components, Oil & Gas, Power Generation

Diameter : 6 mm to 300 mm

Processing : Forged, Rolled

Standard : ASTM, ASME, AMS 5829

Nimonic 75 Round Bar

Length : 1 Meter, 2 Meter, 3 Meter, or as required

Material : Nimonic 75

Application : Construction, industrial, aerospace, gas turbines, heat treatment equipment

Diameter : 5mm to 200mm

Processing : Forged, Rolled, Peeled, Turned

Standard : ASTM, BS, DIN, JIS

Vascomax 300 Round Bar

Length : 16 Meter

Material : Alloy Steel

Application : Construction, Engineering, Automobile Industries

Diameter : 10 mm to 200 mm

Processing : Forged / Rolled

Standard : ASTM A579 / A646

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese