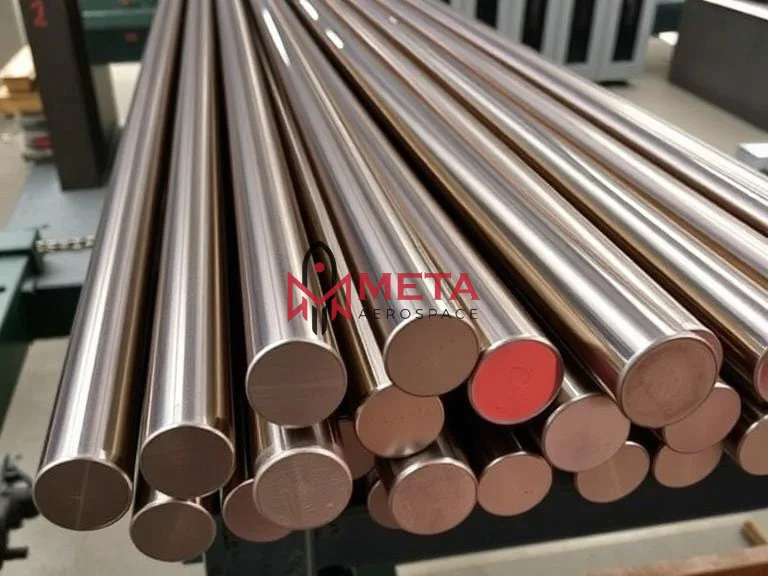

Nimonic 105 Round Bar

Nimonic 105 Round Bar Specification

- Type

- Round Bar

- Grade

- Nimonic 105

- Standard

- ASTM, AMS 5822, BS HR 504, DIN 17742

- Technique

- Hot Rolled, Forged

- Diameter

- 6 mm to 200 mm

- Finish

- Bright, Polished, Black

- Specific Use

- Turbine Blades, Shafts, Fasteners, Engine Components

- Application

- Aerospace, Gas Turbines, Power Generation, Heat Treatment, High-Temperature Environments

- Processing

- Annealed, Solution Treated

- Length

- 100 mm to 6000 mm

- Material

- Nimonic 105

- Tolerance

- H9, H11, or as specified

- Condition

- Solution Annealed

- Hardness

- 200-260 HB

- Heat Resistance

- Stable up to 1050C

- Form

- Bars, Rods, Customized Cuts

- Tensile Strength

- 980 MPa minimum

- Density

- 8.19 g/cm

- Elongation

- Approximately 16%

- Corrosion Resistance

- Excellent resistance to oxidation and corrosion at high temperatures

- Yield Strength

- 735 MPa minimum

- Surface

- Smooth, Clean

- Melting Point

- 1344C - 1380C

About Nimonic 105 Round Bar

What Are Specification Nimonic 105 Round Bar?

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

|---|---|

| Hex Bar Size | 2-100mm A/F |

| Round Bar Size | Diameter: 3-~800mm |

| Flat Bar Size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Angle Bar Size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Square Bar Size | 4 to 100mm |

| Channel Bar | 80 x 40mm to 150 x 90mm section; 5.0 to 6.0mm thickness |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Threaded Bar Billet Size | 1/2 to 495mm Diameter |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Rod, Round, Channel Bar, T-Bar, Flat Bar, Precision Ground Bar, Blocks, Square, Rings, Round Rod, Triangle, Hollow, Rectangle, Threaded, Hex (A/F), Profiles, Half Round Bar, Ingot, Billet, I/H Bar, Forging etc. |

Equivalent material Of Nimonic 105 Round Bar?

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Nimonic Alloy 105 | 2.4634 | N07090 |

Chemical Composition Of Nimonic 105 Round Bar?

| C | Si | Cu | Fe | Mn | Cr | Ti | Al | Co | Mo | Pb | S | B | Zr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.12 | 1.0 | 0.2 | 1.0 | 1.0 | 14.0-15.7 | 0.9-1.5 | 4.5-5.5 | 18.0-22.0 | 4.5-5.5 | 0.0015 | 0.010 | 0.003-0.010 | 0.15 | Bal |

Mechanical Properties Of Nimonic 105 Round Bar?

| Tensile Strength Minimum (psi) | Yield Strength Minimum 0.2% offset (psi) | % Elongation in 2 Minimum |

|---|---|---|

| 167,000 | 112,000 | 25 |

Superior High-Temperature Performance

Engineered for resilience, Nimonic 105 Round Bars maintain mechanical integrity and resist deformation even when exposed to temperatures as high as 1050C. This makes them indispensable in high-stress, high-heat environments found in aerospace and power generation industries, significantly extending component life and reliability.

Excellent Oxidation and Corrosion Resistance

Nimonic 105 exhibits outstanding resistance to oxidation and corrosion, even in highly aggressive atmospheric conditions. Its superior alloy composition ensures prolonged durability in challenging environments, such as gas turbines and heat treatment chambers, contributing to lower maintenance and longer service intervals.

Precision Manufacturing and Customization

Available in various finishesbright, polished, or blackand with customizable dimensions, Nimonic 105 Round Bars are produced using advanced techniques like hot rolling and forging. Each product is solution-annealed for optimum performance and can be tailored to diverse engineering needs, supporting global aerospace and industrial standards.

FAQs of Nimonic 105 Round Bar:

Q: How does the high-temperature stability of Nimonic 105 Round Bar benefit industrial applications?

A: Nimonic 105 Round Bar retains strength and resists deformation at temperatures up to 1050C, reducing the risk of failure in demanding environments such as turbine engines, power generation plants, and heat treatment processes.Q: What is the typical process for manufacturing and finishing Nimonic 105 Round Bars?

A: These bars are manufactured through hot rolling or forging, followed by solution annealing to enhance their microstructure and mechanical properties. Finishing options, including bright, polished, or black, ensure a smooth, clean, corrosion-resistant surface suitable for critical applications.Q: When should Nimonic 105 Round Bars be chosen over other materials?

A: Select Nimonic 105 when components are exposed to sustained high temperatures, oxidative or corrosive environments, and require superior mechanical performance, such as in aerospace engines, gas turbines, or high-performance industrial systems.Q: Where are Nimonic 105 Round Bars typically used in industry?

A: They are widely used in aerospace, gas turbines, heat treatment plants, and power generation sectors for manufacturing turbine blades, shafts, fasteners, and various engine components that demand reliable performance under extreme conditions.Q: What customization options are available for Nimonic 105 Round Bars?

A: Bars can be cut to lengths from 100 mm up to 6000 mm, with diameters ranging from 6 mm to 200 mm. Tolerances such as H9 or H11 can be specified, and diverse surface finishes are available to match unique project requirements.Q: How does Nimonic 105 ensure excellent corrosion and oxidation resistance?

A: The alloys composition, rich in nickel, chromium, and cobalt, offers a robust passive oxide layer that shields components from aggressive gases and oxidizing conditions, particularly at high temperatures.Q: What standards do Nimonic 105 Round Bars comply with?

A: Nimonic 105 Round Bars are supplied according to international standards such as ASTM, AMS 5822, BS HR 504, and DIN 17742, ensuring assured quality and suitability for global industrial requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Other Round Bars Category

Sanicro 28 Round Bar

Standard : ASTM, ASME, EN, DIN

Technique : Hot Rolled / Cold Drawn

Grade : Sanicro 28

Type : Round Bar

Diameter : 6mm 200mm

Finish : Bright, Black, Polished

Nimonic 75 Round Bar

Standard : ASTM, BS, DIN, JIS

Technique : Hot Rolled or Cold Drawn

Grade : Nimonic 75 (UNS N06075)

Type : Round Bar

Diameter : 5mm to 200mm

Finish : Bright, Polished

Nimonic 80S Round Bar

Standard : ASTM, ASME, DIN, EN

Technique : Hot Rolled / Forged

Grade : Nimonic 80A, Nimonic 80S

Type : Round Bar

Diameter : 8mm 200mm

Finish : Bright, Black, Polished

SMO 254 Round Bar

Standard : ASTM A276, ASTM A479, EN 1.4547

Technique : Hot Rolled / Cold Drawn

Grade : 254 SMO

Type : Round Bar

Diameter : 6 mm to 350 mm

Finish : Bright, Polished, Black, Peeled

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese