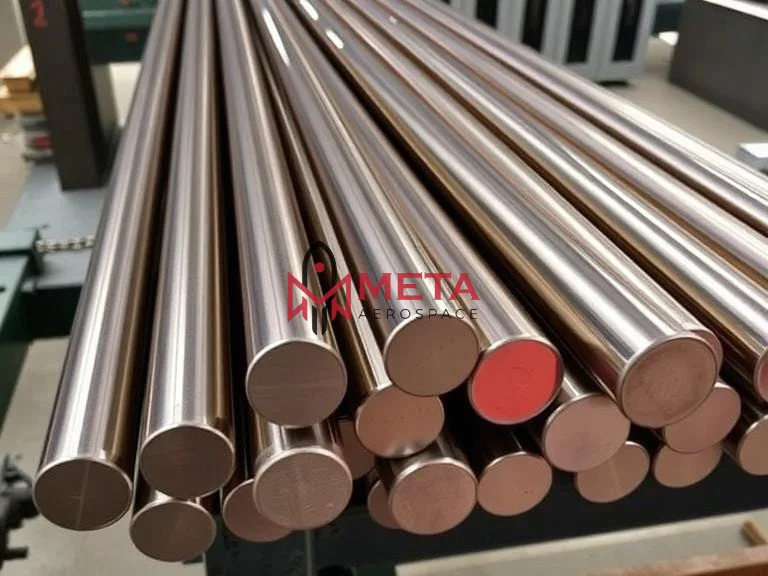

SMO 254 Round Bar

SMO 254 Round Bar Specification

- Processing

- Forged, Peeled, Turned, Polished

- Specific Use

- High chloride environments, Heat exchangers, Process piping

- Grade

- 254 SMO

- Tolerance

- H9, H10, H11 as per requirement

- Standard

- ASTM A276, ASTM A479, EN 1.4547

- Application

- Chemical processing, Marine equipment, Oil & Gas, Pulp & Paper, Desalination plants

- Finish

- Bright, Polished, Black, Peeled

- Material

- SMO 254 (UNS S31254)

- Type

- Round Bar

- Diameter

- 6 mm to 350 mm

- Technique

- Hot Rolled / Cold Drawn

- Length

- 100 mm to 6000 mm (custom cut available)

- Export Packaging

- Standard seaworthy packing (wooden boxes, bundles)

- Elongation

- 35%

- Tensile Strength

- 650 MPa

- Melting Point

- 13201390C

- Density

- 8.00 g/cm

- Yield Strength

- 300 MPa

- Weldability

- Excellent

- Hardness

- 100 HB

- Formability

- Good

- Corrosion Resistance

- Excellent resistance to pitting, crevice and stress corrosion cracking

- Heat Treatment

- Solution Annealed

About SMO 254 Round Bar

What Are Specification SMO 254 Round Bar?

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

|---|---|

| Hex Bar Size | 2-100mm A/F |

| Round Bar Size | Diameter: 3-~800mm |

| Flat Bar Size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Angle Bar Size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Square Bar Size | 4 to 100mm |

| Channel Bar | 80 x 40mm to 150 x 90mm section; 5.0 to 6.0mm thickness |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Threaded Bar Billet Size | 1/2 to 495mm Diameter |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Rod, Round, Channel Bar, T-Bar, Flat Bar, Precision Ground Bar, Blocks, Square, Rings, Round Rod, Triangle, Hollow, Rectangle, Threaded, Hex (A/F), Profiles, Half Round Bar, Ingot, Billet, I/H Bar, Forging etc. |

Equivalent material Of SMO 254 Round Bar?

| STANDARD | WERKSTOFF NR. | UNS | SIS | AFNOR | EN |

|---|---|---|---|---|---|

| SMO 254 | 1.4547 | S31254 | 2378 | Z1 CNDU 20.18.06Az | X1CrNiMoCuN20-18-7 |

Chemical Composition Of SMO 254 Round Bar?

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Ti |

|---|---|---|---|---|---|---|---|---|---|

| SMO 254 | 0.2 max | 1.5 max | 0.75 max | 0.040 | 0.030 max | 18.00 22.00 | - | 0.50 max |

Mechanical Properties Of SMO 254 Round Bar?

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1320-1390 | 650 | 300 | 35 % |

Robust Mechanical and Corrosion Properties

SMO 254 Round Bars are engineered to deliver high tensile ( 650 MPa) and yield strength ( 300 MPa), along with excellent elongation ( 35%). Their exceptional resistance to pitting, crevice, and stress corrosion cracking makes them the preferred material in aggressive chloride environments. The solution-annealed microstructure ensures durability, while controlled hardness ( 100 HB) enhances machinability and formability.

Versatile Applications Across Industries

This grade is widely trusted in sectors such as chemical processing, marine engineering, oil & gas industries, pulp & paper, and desalination plants. Its robust attributes and adaptability make it suitable for heat exchangers, high-stress process piping, and other systems exposed to harsh chemical and saltwater conditions.

Customization and Export-Ready Packaging

Offered in diameters ranging from 6 mm to 350 mm and lengths up to 6000 mm, SMO 254 Round Bars can be custom cut to precise requirements. Available finishes include bright, polished, black, peeled, and turned. Every bar is export-packaged in standard seaworthy wooden boxes or bundles, ensuring quality is preserved during global transit.

FAQs of SMO 254 Round Bar:

Q: How is the SMO 254 Round Bar processed and finished before delivery?

A: SMO 254 Round Bars are manufactured through hot rolling or cold drawing, followed by processes such as forging, peeling, turning, and polishing. The bars are solution-annealed to enhance their mechanical and corrosion-resistant properties. Customers can choose from a variety of finishes, including bright, polished, black, or peeled, to suit specific application requirements.Q: What benefits does SMO 254 Round Bar offer in high chloride environments?

A: Thanks to its superior alloy composition, SMO 254 offers excellent resistance to pitting, crevice, and stress corrosion cracking, even in high chloride settings. This makes the round bar ideal for marine equipment, desalination plants, and chemical processing systems exposed to saltwater or aggressive chemicals.Q: When should I use SMO 254 Round Bar over standard stainless steels?

A: SMO 254 Round Bar should be chosen for applications demanding high corrosion resistance and mechanical strength, especially where exposure to chlorides or aggressive media is significant, such as in seawater systems, pulp & paper, or oil & gas process piping.Q: Where can SMO 254 Round Bars be used most effectively?

A: These bars are best utilized in industries like marine engineering, chemical processing, oil & gas, pulp & paper, and desalination plants. Their resistance to localized corrosion makes them especially effective in heat exchangers, pumps, and piping subjected to corrosive environments.Q: What standards do SMO 254 Round Bars comply with?

A: SMO 254 Round Bars are produced in accordance with international standards such as ASTM A276, ASTM A479, and EN 1.4547. Compliance ensures consistent material quality and suitability for critical industrial applications.Q: How are SMO 254 Round Bars packaged for export?

A: For safe international shipping, these round bars are packed in standard seaworthy wooden boxes or bundled, protecting them from mechanical damage and environmental exposure during transit.Q: What are the available size and tolerance options for SMO 254 Round Bars?

A: Diameters range from 6 mm to 350 mm with custom lengths up to 6000 mm. Tolerances such as H9, H10, and H11 are offered as per customer specification, ensuring precise compatibility for diverse engineering needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Other Round Bars Category

Nimonic 105 Round Bar

Length : 100 mm to 6000 mm

Technique : Hot Rolled, Forged

Diameter : 6 mm to 200 mm

Type : Round Bar

Material : Nimonic 105

Finish : Bright, Polished, Black

Nimonic 75 Round Bar

Length : 1 Meter, 2 Meter, 3 Meter, or as required

Technique : Hot Rolled or Cold Drawn

Diameter : 5mm to 200mm

Type : Round Bar

Material : Nimonic 75

Finish : Bright, Polished

Nimonic 80S Round Bar

Length : As per requirement / Customized

Technique : Hot Rolled / Forged

Diameter : 8mm 200mm

Type : Round Bar

Material : Nimonic 80S

Finish : Bright, Black, Polished

Maraging Steel C350 Round Bar

Length : 1 to 6 meters (custom lengths available)

Technique : Hot Rolled, Cold Drawn

Diameter : 4 mm to 300 mm

Type : Round Bar

Material : Maraging Steel C350

Finish : Bright, Black, Polished

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese