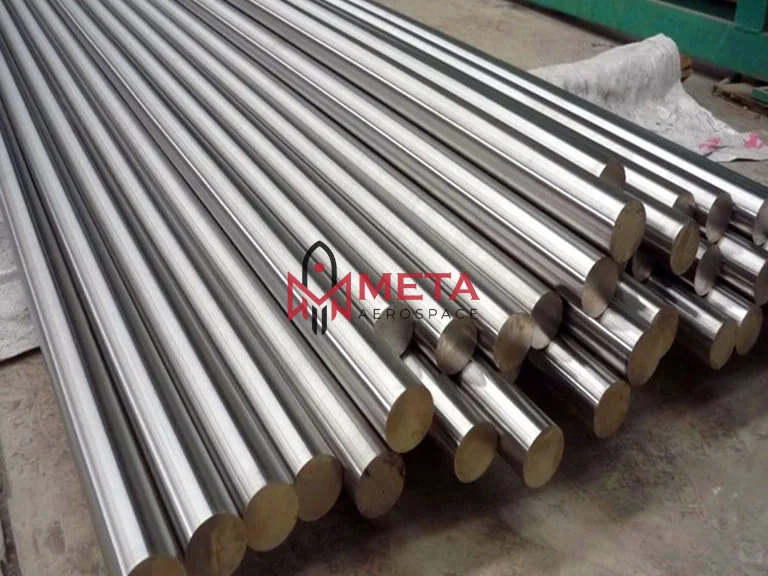

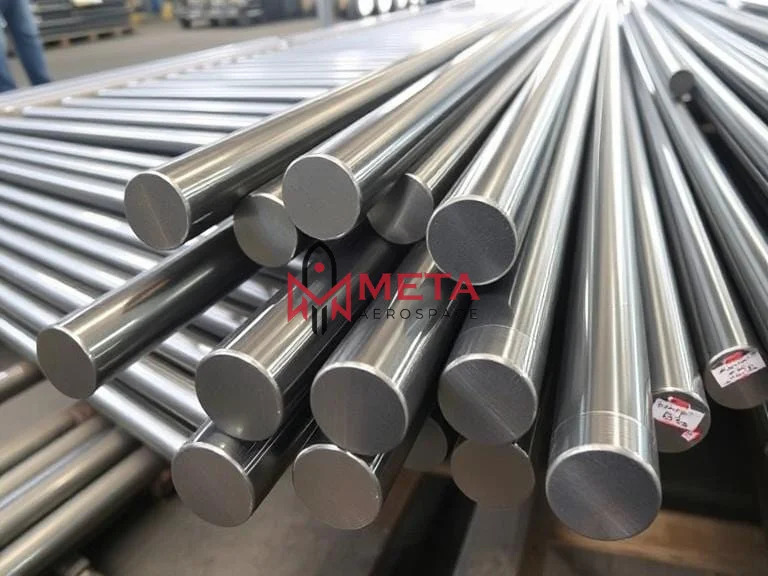

Nimonic 75 Round Bar

Nimonic 75 Round Bar Specification

- Type

- Round Bar

- Finish

- Bright, Polished

- Application

- Construction, industrial, aerospace, gas turbines, heat treatment equipment

- Technique

- Hot Rolled or Cold Drawn

- Length

- 1 Meter, 2 Meter, 3 Meter, or as required

- Diameter

- 5mm to 200mm

- Specific Use

- High-temperature structural components

- Material

- Nimonic 75

- Grade

- Nimonic 75 (UNS N06075)

- Tolerance

- H9, H11, H13, or as per specification

- Processing

- Forged, Rolled, Peeled, Turned

- Standard

- ASTM, BS, DIN, JIS

- Packaging

- Export worthy standard packing

- Yield Strength

- min 275 MPa

- Hardness

- Rockwell B90 max

- Surface Condition

- Mill, Smooth, Black, Pickled

- Temperature Range

- Up to 1000C

- Elongation

- min 35%

- Shape

- Round

- Supply Condition

- Solution Annealed

- Tensile Strength

- min 690 MPa

- Melting Point

- 1320-1380C

- Corrosion Resistance

- Excellent oxidation and scaling resistance

- Density

- 8.19 g/cm

About Nimonic 75 Round Bar

What Are Specification Nimonic 75 Round Bar?

| Dimension : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

|---|---|

| Grade : | Nimonic 75 (UNS No. N06075) Round Bars |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Form : | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Surface : | Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline |

| Application : | Chemical process, Food processing, Petrochemical, Pollution control, Pulp and Paper, Refining |

| Condition : | Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished. |

Equivalent material Of Nimonic 75 Round Bar?

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Nimonic Alloy 75 | - | N06075 |

Chemical Composition Of Nimonic 75 Round Bar?

| Grade | C | Ni | Cu | Cr | Ti | Fe | Mn |

|---|---|---|---|---|---|---|---|

| Nimonic Alloy 75 | 0.08 / 0.15 | Bal | 0.5 max | 18.9 - 21.0 | 0.2 / 0.6 | 5.0 max | 1.0 max |

Mechanical Properties Of Nimonic 75 Round Bar?

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Nimonic Alloy 75 | 8.1 g/cm3 | Psi 110000, MPa 760 | Psi 55100, MPa 380 | 45 % |

Superior Oxidation and Thermal Resistance

Nimonic 75 Round Bar excels in high-temperature environments, offering exceptional resistance to oxidation and scaling up to 1000C. Its unique composition ensures structural stability and longevity, making it an ideal choice for demanding applications in aerospace, gas turbines, and industrial heat equipment. The alloy maintains its mechanical integrity even under severe thermal cycling, providing reliable performance for critical components.

Versatile Sizing and Finishing Options

Available in diameters from 5mm to 200mm and lengths of 1, 2, or 3 meters (or as required), Nimonic 75 Round Bar suits various project specifications. The bars can be supplied in smooth, black, mill, pickled, bright, or polished finish based on the application. Processing techniques such as hot rolling, cold drawing, forging, peeling, and turning allow for precise customization and adherence to strict international tolerances like H9, H11, and H13.

FAQs of Nimonic 75 Round Bar:

Q: How is Nimonic 75 Round Bar typically manufactured and supplied?

A: Nimonic 75 Round Bar is produced using hot rolling or cold drawing, followed by solution annealing to achieve optimal mechanical properties. It is available in lengths of 1m, 2m, 3m, or as specified, with diameters ranging from 5mm to 200mm. The bars are supplied in various surface conditions (mill, smooth, black, pickled, bright, or polished) and packaged in export-worthy standard crates for safe global delivery.Q: What makes Nimonic 75 Round Bar suitable for high-temperature applications?

A: Its high nickel-chromium content endows the Nimonic 75 Round Bar with superior oxidation and scaling resistance at temperatures up to 1000C. These properties, along with a high melting point of 1320-1380C and an excellent combination of yield and tensile strength, make it ideal for demanding environments like gas turbines, heat treatment equipment, and aerospace construction.Q: When should Nimonic 75 Round Bar be used over other high-temperature alloys?

A: Choose Nimonic 75 Round Bar when your application demands consistent mechanical performance, excellent oxidation resistance, and high structural integrity in temperatures up to 1000C. Its reliable elongation and hardness, combined with resistance to corrosive environments, make it preferable for heat-exposed structural components and parts subject to severe thermal cycling.Q: Where can Nimonic 75 Round Bar be applied?

A: Nimonic 75 Round Bar is widely used in industries such as construction, industrial processes, aerospace, gas turbines, and heat treatment equipment. Its robustness and heat resistance are particularly beneficial for high-temperature structural components and environments where thermal stability is critical.Q: What benefits does the solution annealed supply condition offer for Nimonic 75 Round Bar?

A: The solution annealing process enhances the bars mechanical properties, increases resistance to intergranular corrosion, and ensures uniform structure throughout the material. This results in improved toughness, ductility, and overall durability, making it better suited to harsh and fluctuating service conditions.Q: How does the tolerance specification impact the use of Nimonic 75 Round Bar?

A: Precise tolerances such as H9, H11, and H13 ensure the round bars meet stringent dimensional requirements for critical engineering applications. Tight tolerances enable reliable assembly and integration into complex systems, reducing machining time and improving fit in end-use components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Other Round Bars Category

Waspaloy Round Bar

Diameter : 5 mm to 400 mm

Length : 36 Meter

Grade : Waspaloy UNS N07001

Material : Waspaloy

Specific Use : High Strength and Corrosion Resistance at Elevated Temperatures

Finish : Polished

Maraging Steel C250 Round Bar

Diameter : 4 mm to 350 mm

Length : 100 mm to 6000 mm

Grade : C250

Material : Maraging Steel C250

Specific Use : High strength and toughness applications

Finish : Polished, Bright

Maraging Steel C300 Round Bar

Diameter : 4 mm 350 mm

Length : 100 mm 6000 mm

Grade : C300 (18Ni (300))

Material : Maraging Steel

Specific Use : Precision Components, High Strength Structural Parts

Finish : Bright, Polished, Black

Sanicro 28 Round Bar

Diameter : 6mm 200mm

Length : 2 Meter 6 Meter (Custom Cut Available)

Grade : Sanicro 28

Material : Sanicro 28 (UNS N08028)

Specific Use : Corrosionresistant structural components

Finish : Bright, Black, Polished

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese