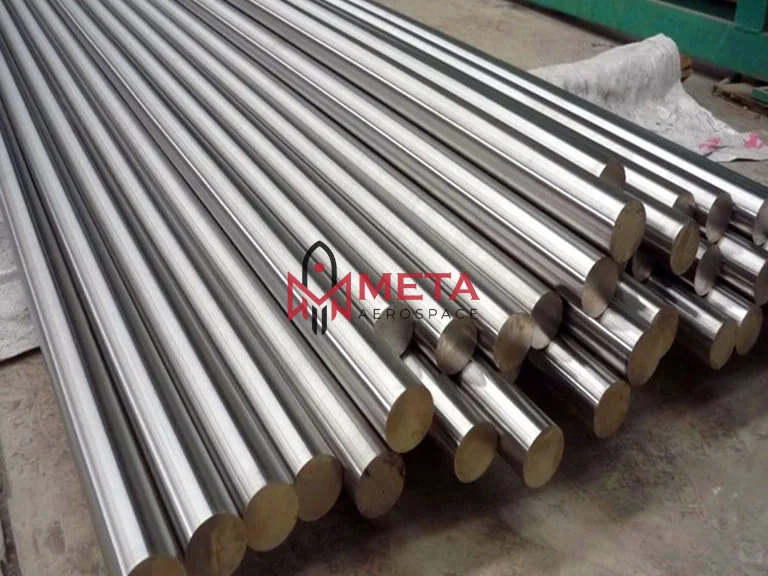

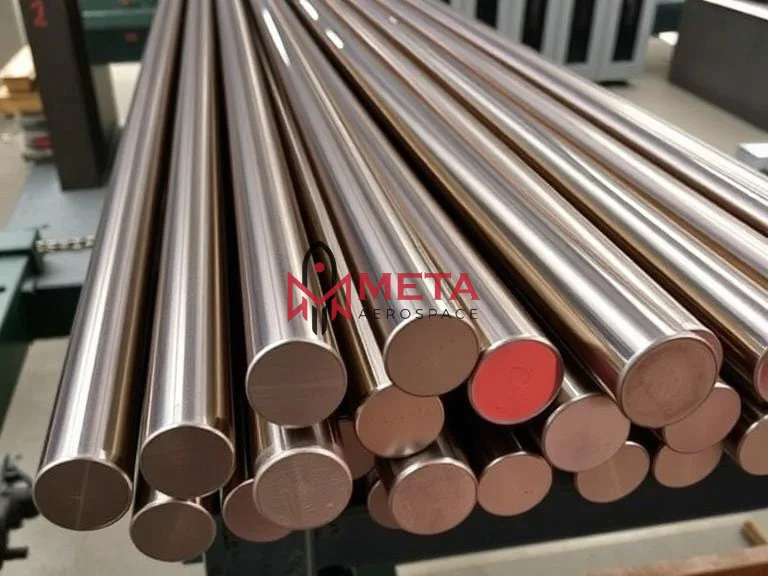

Maraging Steel C250 Round Bar

Maraging Steel C250 Round Bar Specification

- Diameter

- 4 mm to 350 mm

- Length

- 100 mm to 6000 mm

- Finish

- Polished, Bright

- Technique

- Hot Rolled / Cold Drawn

- Tolerance

- H9, H11, or as per request

- Specific Use

- High strength and toughness applications

- Application

- Aerospace, tooling, defense, machinery, die casting, and high-performance structural components

- Standard

- ASTM, AMS, DIN, EN, UNS K92890

- Material

- Maraging Steel C250

- Processing

- Solution Annealed, Aged

- Type

- Round Bar

- Grade

- C250

- Yield Strength

- ~1700 MPa after aging

- Density

- 8.0 g/cm

- Ultimate Tensile Strength

- ~1900 MPa

- Surface Condition

- Peeled, Polished, Turned

- Corrosion Resistance

- Medium

- Delivery Condition

- Solution Treated & Aged

- Formability

- Good, suitable for machining and forming

- Hardness

- Up to 55 HRC after aging

- Melting Point

- 1413C

- Elongation at Break

- 8-10%

About Maraging Steel C250 Round Bar

What Are Specification Maraging Steel C250 Round Bar?

| Standard | AMS 6512, MIL-S-46850, ASTM A538 |

|---|---|

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

| Round Bar Size | Diameter: 3-~800mm |

| Flat Bar Size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Square Bar Size | 4 to 100mm |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Rod, Round, Flat Bar, Square, Round Rod, Forging etc. |

Equivalent material Of Maraging Steel C250 Round Bar?

| Alloy Name | Trade Name | UNS No. | British Specs | American Specs | German Specs |

|---|---|---|---|---|---|

| Maraging 250 | Udimar 250 Maraging C250 Vascomax C250 | UNS K92890 | BS S162 | AMS 6512 Bar MIL-S-46850 Type 3 | Werkstoff 1.6359 |

Chemical Composition Of Maraging Steel C250 Round Bar?

| Weight% | Ni | Co | Mn | Si | C | Al | Mo | S | P | Ti | Fe | Cr | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C250 | 17.0 / 19.0 | 7.0 / 8.5 | 0.10 max | 0.10 max | 0.03 max | 0.05 / 0.15 | 4.6 / 5.2 | 0.010 max | 0.010 max | 0.3 / 0.5 | Bal | 0.50 | 0.50 |

Mechanical Properties Of Maraging Steel C250 Round Bar?

| Material | Condition | Ultimate Tensile (min) | Yield Strength (Min) | Elongation in 4D % (min) | Hardness | ||

|---|---|---|---|---|---|---|---|

| Mpa | Ksi | Mpa | Ksi | ||||

| Alloy Maraging C250 | After Maraging heat treatment 900F | 1758 | 255 | 1724 | 250 | 6 | 48 HRC |

Precision and Performance in Every Bar

Maraging Steel C250 Round Bars are engineered to meet rigorous performance requirements, offering high yield and tensile strengths post-aging. The combination of good ductility and toughness, even at high hardness, makes them exceptionally reliable for structural components in critical industries like aerospace, defense, and tooling.

Versatile Finishes and Customization Options

Available in peeled, polished, and turned surface finishes, these round bars meet diverse application needs. Customers can select from a wide range of diameters, lengths, and tolerances (H9, H11, or tailored), ensuring each bar fits the required mechanical and dimensional criteria for specific projects.

Superior Processing and Quality Standards

Manufactured with advanced hot rolled or cold drawn techniques, the bars undergo solution annealing and aging for optimal properties. Compliance with ASTM, AMS, DIN, EN, and UNS K92890 demonstrates their industry-standard reliability. Each bar undergoes stringent quality checks and is delivered in a solution-treated and aged condition.

FAQs of Maraging Steel C250 Round Bar:

Q: How is Maraging Steel C250 Round Bar processed to achieve its mechanical properties?

A: Maraging Steel C250 Round Bar undergoes solution annealing followed by aging heat treatment. This process enhances its strength, hardness, and toughness, yielding a hardness up to 55 HRC and tensile strength around 1900 MPa, making it suitable for demanding applications.Q: What applications is Maraging Steel C250 Round Bar commonly used for?

A: This round bar is widely utilized in aerospace structures, tooling, defense equipment, high-performance machinery, die-casting components, and other applications requiring high strength, toughness, and reliable dimensional stability.Q: When should Maraging Steel C250 be chosen over conventional alloy steels?

A: Maraging Steel C250 is selected when high yield and tensile strengths, excellent toughness after aging, and good machinability are essential, especially in situations demanding precise tolerances and reliable performance under stresssuch as aerospace or precision tool manufacturing.Q: Where is Maraging Steel C250 Round Bar manufactured and supplied from?

A: These bars are produced and exported by reputable manufacturers, suppliers, and traders in India, adhering to global standards like ASTM, AMS, DIN, EN, and UNS K92890 for consistent quality and performance.Q: What benefits does the polished or turned finish provide?

A: A polished or turned surface delivers smoother finishes, reducing friction and wear in moving parts, and enhances dimensional accuracy. It also improves aesthetics and may facilitate improved corrosion resistance compared to rougher surfaces.Q: How is Maraging Steel C250 Round Bar delivered and what tolerances are available?

A: The bars are delivered in a solution treated and aged condition, ready for machining or forming. Standard tolerances include H9, H11, or custom requirements, ensuring compatibility with precise engineering needs.Q: What is the corrosion resistance level of Maraging Steel C250 and is additional protection recommended?

A: Maraging Steel C250 provides medium corrosion resistance, which suffices for many applications. However, if used in highly corrosive environments or for extended outdoor exposure, supplementary protective coatings or regular maintenance may be advisable.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Other Round Bars Category

Waspaloy Round Bar

Specific Use : High Strength and Corrosion Resistance at Elevated Temperatures

Application : Aerospace, Gas Turbine Components, High Temperature Applications

Standard : ASTM, DIN, JIS, EN standards

Material : Waspaloy

Processing : Forged / Rolled

Type : Round Bar

Vascomax 250 Round Bar

Specific Use : High Strength Structural Components

Application : Aerospace, Defense, Tooling, Shafts, Fasteners

Standard : ASTM A579 / A604

Material : Vascomax 250 (Maraging Steel)

Processing : Heat Treated

Type : Round Bar

Nimonic 105 Round Bar

Specific Use : Turbine Blades, Shafts, Fasteners, Engine Components

Application : Aerospace, Gas Turbines, Power Generation, Heat Treatment, HighTemperature Environments

Standard : ASTM, AMS 5822, BS HR 504, DIN 17742

Material : Nimonic 105

Processing : Annealed, Solution Treated

Type : Round Bar

Nimonic 80S Round Bar

Specific Use : Aerospace Components, Gas Turbine Parts

Application : Engineering, Construction and Manufacturing

Standard : ASTM, ASME, DIN, EN

Material : Nimonic 80S

Processing : Peeled, Centreless Ground

Type : Round Bar

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese