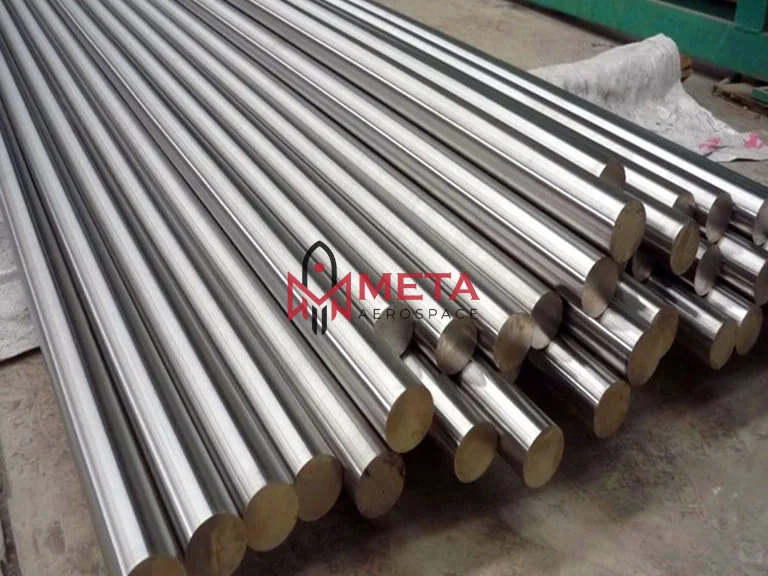

Waspaloy Round Bar

Waspaloy Round Bar Specification

- Grade

- Waspaloy UNS N07001

- Tolerance

- H9, H11, or as required

- Type

- Round Bar

- Technique

- Hot Rolled

- Finish

- Polished

- Length

- 3-6 Meter

- Material

- Waspaloy

- Application

- Aerospace, Gas Turbine Components, High Temperature Applications

- Diameter

- 5 mm to 400 mm

- Processing

- Forged / Rolled

- Standard

- ASTM, DIN, JIS, EN standards

- Specific Use

- High Strength and Corrosion Resistance at Elevated Temperatures

- Melting Range

- 13201365C

- Surface Condition

- Bright, Smooth, Free from Scale

- Packaging

- Standard Export Packing or As Required

- Yield Strength

- 758 MPa min

- Elongation

- 20% min

- Hardness

- Rockwell C35-45

- Condition

- Solution Annealed and Aged

- Tensile Strength

- 965 MPa min

- Density

- 8.19 g/cm

About Waspaloy Round Bar

What Are Specification Waspaloy Round Bar?

| Standard | AMS 6514, AMS 6515, MIL-S-46850, ASTM A538 |

|---|---|

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

| Round Bar Size | Diameter: 3-~800mm |

| Flat Bar Size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Square Bar Size | 4 to 100mm |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Rod, Round, Flat Bar, Square, Round Rod, Forging etc. |

Equivalent material Of Waspaloy Round Bar?

| Alloy Name | UNS | WNR. |

|---|---|---|

| Waspaloy | N07001 | 2.4654 |

Chemical Composition Of Waspaloy Round Bar?

| Cr | Ni | Mo | Co | Al | Ti | B | C | Zr | Fe | Mn | Si | P | S | Cu | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MIN | 18.00 | -- | 3.50 | 12.00 | 1.20 | 2.75 | 0.003 | 0.02 | 0.02 | -- | -- | -- | -- | -- | -- |

| MAX | 21.00 | Balance | 5.00 | 15.00 | 1.60 | 3.25 | 0.01 | 0.10 | 0.08 | 2.00 | 0.10 | 0.15 | 0.015 | 0.015 | 0.10 |

Mechanical Properties Of Waspaloy Round Bar?

| Temperature, F | 70 | 1200 | 1400 | 1600 |

|---|---|---|---|---|

| Ultimate Tensile Strength, ksi | 193 | 173 | 140 | 79 |

| 0.2% Yield Strength, ksi | 132 | 112 | 112 | 60 |

| Elongation, % | 27 | 21 | 12 | 12 |

| Hardness, Rockwell C | 34-40 | - | - | - |

Superior Strength in Extreme Conditions

Waspaloy round bars excel in high-stress, high-temperature environments thanks to their unique chemical composition and heat treatment. These bars maintain mechanical integrity under prolonged exposure to temperatures up to the alloys melting range of 13201365C, making them indispensable for aerospace and gas turbine industries.

Precision Manufacturing and Finishing

Our Waspaloy round bars are produced using advanced forging or rolling techniques, meeting tight tolerances (H9, H11, or as required). The solution-annealed and aged process ensures optimal grain structure, while polished, bright surfaces free from scale offer both aesthetic appeal and functional reliability.

FAQs of Waspaloy Round Bar:

Q: How is Waspaloy round bar processed to achieve its properties?

A: Waspaloy round bars undergo hot rolling or forging, followed by solution annealing and aging treatments. This strengthens the material, optimizes its mechanical properties, and ensures exceptional resistance to high temperatures and corrosion.Q: What applications are Waspaloy round bars best suited for?

A: These bars are ideal for aerospace, gas turbine components, and other high-temperature applications where superior strength and corrosion resistance are critical, thanks to their ability to perform reliably at elevated temperatures.Q: When should I choose Waspaloy round bar over other alloys?

A: Waspaloy is the recommended choice when your application requires high tensile strength, excellent oxidation resistance, and stability at temperatures exceeding the limits of standard stainless steels or other superalloys.Q: Where are Waspaloy round bars manufactured and exported from?

A: We are a prominent manufacturer, exporter, supplier, and trader based in India, delivering Waspaloy round bars to clients globally with standard export packing or custom packaging as required.Q: What are the benefits of the solution annealed and aged condition in Waspaloy round bars?

A: Solution annealing and aging enhance the alloys microstructure, resulting in greater mechanical strength, improved ductility, and superior performance in high-stress environments.Q: How is the surface condition of Waspaloy round bars maintained?

A: Each bar is meticulously polished and inspected to ensure a bright, smooth surface free from scale, meeting stringent quality requirements for aerospace and industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Other Round Bars Category

Maraging Steel C350 Round Bar

Processing : Aged and Solution Annealed

Standard : ASTM A579, AMS 6512

Specific Use : Highstrength structural applications

Material : Maraging Steel C350

Length : 1 to 6 meters (custom lengths available)

Application : Aerospace, Tooling, Engineering Components, and Defense Equipment

Maraging Steel C300 Round Bar

Processing : Annealed, Solution Treated & Aged

Standard : ASTM A579 / A579M, AMS 6514

Specific Use : Precision Components, High Strength Structural Parts

Material : Maraging Steel

Length : 100 mm 6000 mm

Application : Aerospace, Tooling, Moulds, Defense, Engineering Components

Nimonic 105 Round Bar

Processing : Annealed, Solution Treated

Standard : ASTM, AMS 5822, BS HR 504, DIN 17742

Specific Use : Turbine Blades, Shafts, Fasteners, Engine Components

Material : Nimonic 105

Length : 100 mm to 6000 mm

Application : Aerospace, Gas Turbines, Power Generation, Heat Treatment, HighTemperature Environments

Nimonic 90 Round Bar

Processing : Forged, Rolled

Standard : ASTM, ASME, AMS 5829

Specific Use : Manufacturing components exposed to high temperatures and stress

Material : Nimonic 90

Length : 100 mm to 6000 mm

Application : Aerospace, Gas Turbine Components, Oil & Gas, Power Generation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese