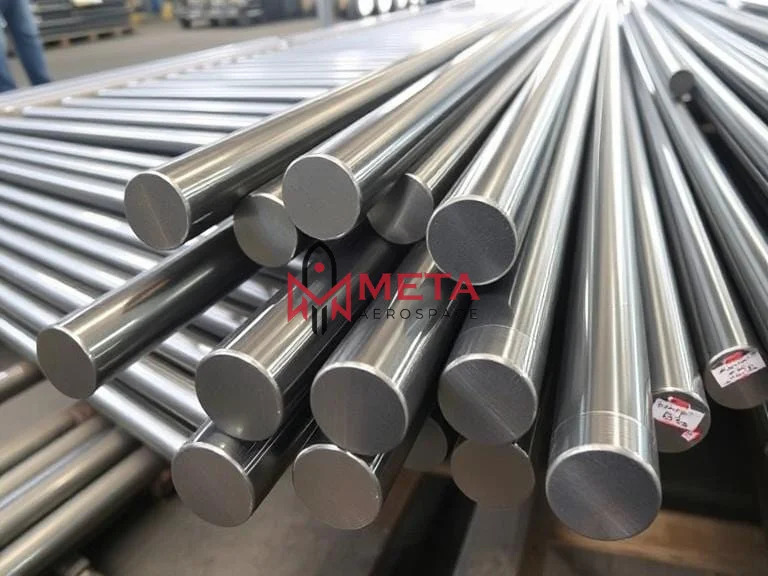

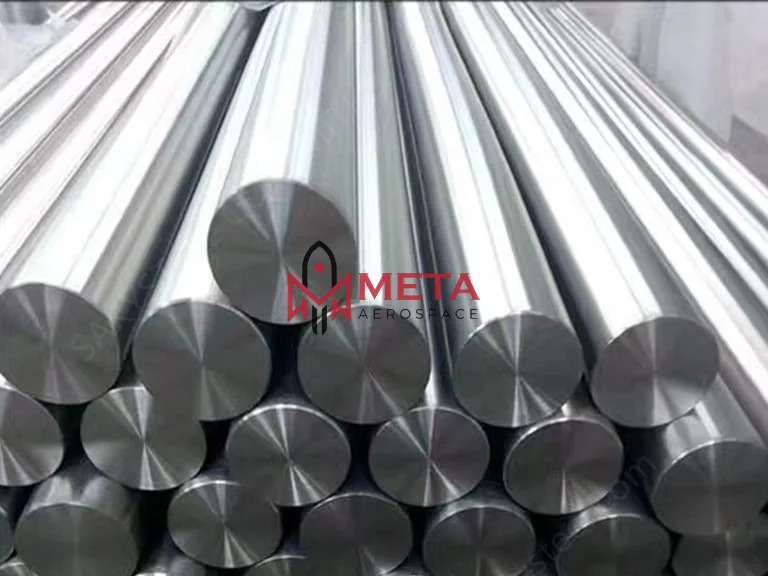

Sanicro 28 Round Bar

Sanicro 28 Round Bar Specification

- Grade

- Sanicro 28

- Length

- 2 Meter 6 Meter (Custom Cut Available)

- Specific Use

- Corrosion-resistant structural components

- Processing

- Annealed, Peeled, Ground

- Diameter

- 6mm 200mm

- Tolerance

- H9, H11, K12 or as specified

- Technique

- Hot Rolled / Cold Drawn

- Application

- Chemical processing, oil and gas, seawater applications, pollution control, pulp & paper industry

- Material

- Sanicro 28 (UNS N08028)

- Standard

- ASTM, ASME, EN, DIN

- Type

- Round Bar

- Finish

- Bright, Black, Polished

- Elongation

- 35%

- MOQ

- 100 Kg

- Surface Condition

- Clean & defect free

- Packaging

- Wooden cases or as required

- Hardness

- 230 HB

- Stock Availability

- Ready stock or on order basis

- Weldability

- Good

- Color

- Silver / Metallic

- Tensile Strength

- 650 MPa

- Corrosion Resistance

- Excellent resistance to pitting, crevice, and stress corrosion

- Yield Strength

- 300 MPa

- Melting Range

- 1260 1320C

- Density

- 8.0 g/cm

About Sanicro 28 Round Bar

What Are Specification Sanicro 28 Round Bar?

| Specifications | DIN, EN, ASTM, JIS, ASME, BS, AISI |

|---|---|

| 28 Alloy Round Bars size | Diameter: 3-~20mm |

| Alloy 28 Flat Bars size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Alloy 28 Angle Bars size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Alloy 28 Channel Bars | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Sanicro 28 Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Alloy 28 Billet Size | 1/2 to 495mm Diameter |

| Alloy 28 Rectangle Bar Size | 33 x 30mm to 295 x 1066mm |

| Alloy 28 Hex Bar size | 2-100mm A/F |

| Alloy 28 Hollow Bars | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Diameter | 20mm, 30mm, 50mm, 80mm, 100mm, 150mm, 200mm, 500mm |

| Length | 1m-12m or as required |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Finish | hot rolled annealed, peeled, Bright, hot-worked and cold-worked rod and bar, centreless ground, Centreless Ground and Black, Polish, Cold Rolled (CR), hot rolled ( R), smooth turned, Cold (bright) drawn, Grinding, slit rolled edge, Rough Turned. |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Cold Drawn, Hot Rolled, Forged Round Bars, Cold Rolled, Rod |

| Processing | Bars cutting to 650mm |

| Form | Rod, Round, Channel Bars, T-Bars, Flat Bars, Precision Ground Bars, Blocks, Square, Round Rod, Triangle, Hollow, Rectangle, Threaded, Hex (A/F), Profiles, Half Round Bars, Ingot, Billet, I/H Bars, Forging etc. |

Equivalent material Of Sanicro 28 Round Bar?

| STANDARD | WERKSTOFF NR. | UNS | EN |

|---|---|---|---|

| Alloy 28 | 1.4563 | N08028 | X1NiCrMoCuN31-27-4 |

Chemical Composition Of Sanicro 28 Round Bar?

| Grade | C | Si | Mn | P | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|

| Alloy 28 | 0.02 max | 0.70 max | 2.00 max | 0.03 max | 26.00 28.00 | 30.00 32.00 | 19.00 21.00 | 0.11 max |

Mechanical Properties Of Sanicro 28 Round Bar?

| Element | Hardness | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

|---|---|---|---|---|

| Alloy 28 | 230 | 220 | 500 750 | 30 % |

Superior Corrosion Resistance for Demanding Environments

Sanicro 28 Round Bars are engineered to provide outstanding resistance against pitting, crevice, and stress corrosion. This makes them ideal for use in aggressive chemical processing, oil and gas installations, seawater systems, and pollution control equipment. Their corrosion-resistant properties ensure long-lasting service life even under severe conditions.

Tailored Specifications to Fit Critical Applications

Available in diameters from 6mm to 200mm and lengths between 2 to 6 meters, Sanicro 28 Round Bars can also be custom-cut to meet unique project needs. Processing options such as annealed, peeled, or ground finishesalong with tight dimensional tolerancesensure optimal fit for various structural and mechanical uses.

Consistent Quality with International Certification

These round bars comply with ASTM, ASME, EN, and DIN standards, guaranteeing reliability and traceability. Rigorous quality control and professional packaging in wooden cases or as required maintain product integrity during transport, making them a trusted choice for exporters, manufacturers, and industrial users.

FAQs of Sanicro 28 Round Bar:

Q: How does Sanicro 28 Round Bar provide excellent corrosion resistance in industrial environments?

A: Sanicro 28 is formulated with a unique alloy composition that delivers exceptional resistance to pitting, crevice, and stress corrosion. This makes it ideal for use in chemical processing, seawater, and oil and gas industries where exposure to aggressive media is common.Q: What are the standard available sizes and surface finish options for Sanicro 28 Round Bar?

A: These bars are available in diameters ranging from 6mm to 200mm and lengths from 2 to 6 meters, with custom cuts upon request. Surface finishes include bright, black, and polished, and the bars are supplied clean and defect-free for immediate use.Q: When should I choose Sanicro 28 Round Bar over other stainless steel options?

A: Choose Sanicro 28 when your application demands superior corrosion resistance, particularly against pitting and stress corrosion, and requires high mechanical strength. Its preferred for harsh chemical processing, seawater, pollution control, and pulp and paper industry applications.Q: Where can Sanicro 28 Round Bars be sourced, and are custom specifications accommodated?

A: Sanicro 28 Round Bars are supplied by exporters, manufacturers, suppliers, and traders throughout India, with delivery available from ready stock or on order. Custom dimensions, finishes, and packaging can be arranged based on specific project requirements.Q: How are Sanicro 28 Round Bars processed to ensure quality and mechanical properties?

A: These bars are manufactured using hot rolled or cold drawn techniques, followed by processes like annealing, peeling, or grinding, to achieve clean surfaces and consistent mechanical strength. Strict quality controls and adherence to ASTM, ASME, EN, and DIN standards guarantee dependable performance.Q: What is the minimum order quantity (MOQ) and how are the bars packaged for shipment?

A: The minimum order quantity for Sanicro 28 Round Bar is 100 Kg. Bars are securely packaged in wooden cases or as specified by the customer to ensure safe transport and delivery worldwide.Q: What benefits does using Sanicro 28 Round Bar offer for structural and mechanical applications?

A: Sanicro 28 Round Bars deliver high tensile and yield strength along with superior ductility and corrosion resistance, enabling safe and reliable operation in structurally demanding and chemically aggressive environments, while offering longevity and reduced maintenance needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Other Round Bars Category

A286 Round Bar

Specific Use : High Strength and Oxidation Resistance at Elevated Temperatures

Technique : Hot Rolled, Cold Drawn

Tolerance : +/ 0.01mm

Grade : A286

Length : Custom Cut, up to 6 meters

Finish : Bright, Black, Polished

Refractaloy 26 Round Bar

Specific Use : Furnace Parts, Heat Exchangers, Chemical Processing

Technique : Forged / Rolled

Tolerance : h9, h11, or as required

Grade : Refractaloy 26

Length : 100 mm to 6000 mm

Finish : Bright / Black / Polished

Maraging Steel C300 Round Bar

Specific Use : Precision Components, High Strength Structural Parts

Technique : Forged / Hot Rolled / Cold Drawn

Tolerance : H9, H10, H11 or as per requirement

Grade : C300 (18Ni (300))

Length : 100 mm 6000 mm

Finish : Bright, Polished, Black

253 MA [S30815] Round Bar

Specific Use : High Temperature Components, Kiln Liners, Furnace Parts

Technique : Hot Rolled, Forged

Tolerance : H9, H11, or as specified

Grade : 253 MA

Length : 3 meter to 6 meter or as required

Finish : Bright, Black, Polished

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

![253 MA [S30815] Round Bar](https://cpimg.tistatic.com/11449080/b/4/253-MA-S30815-Round-Bar..webp)

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese