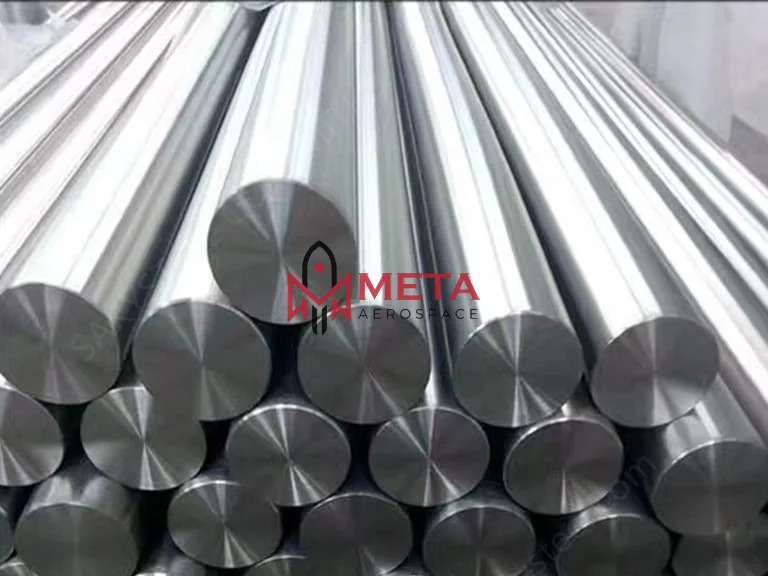

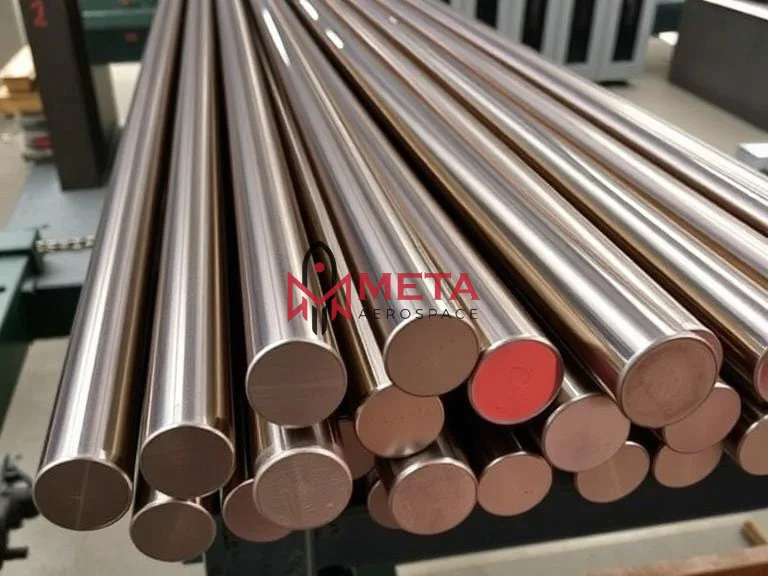

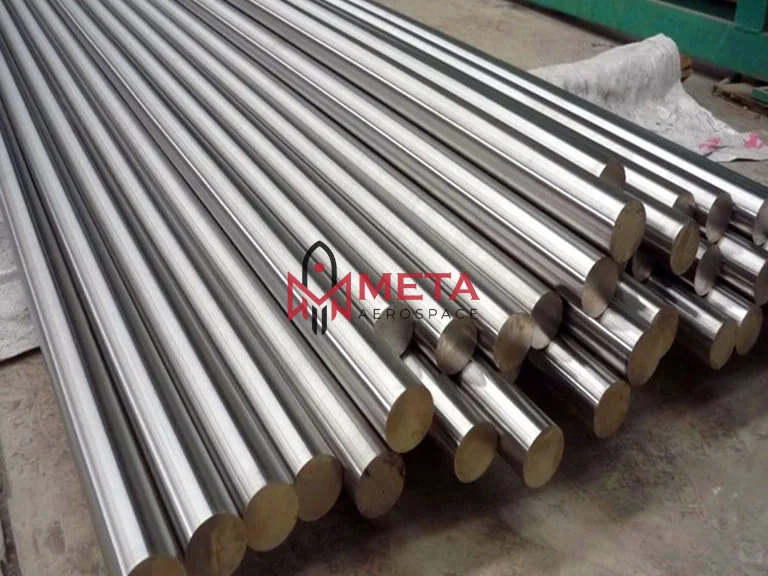

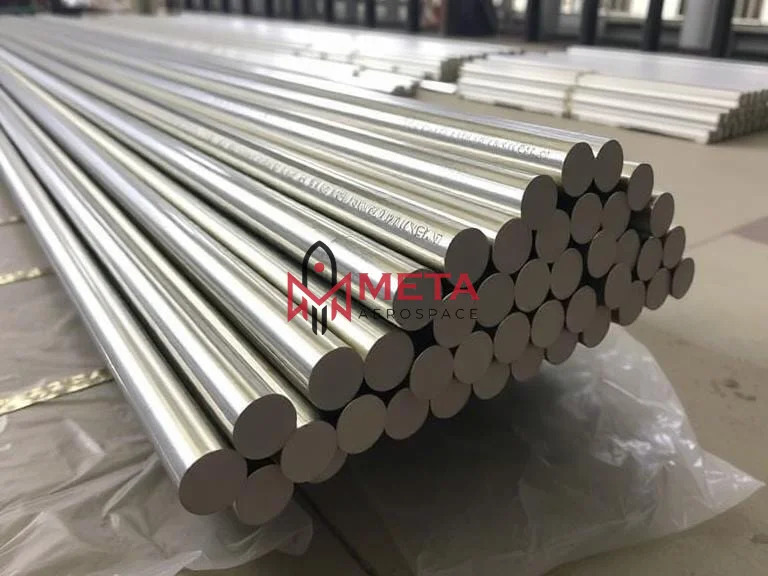

A286 Round Bar

A286 Round Bar Specification

- Standard

- ASTM A286, AMS 5731, AMS 5732

- Application

- Aerospace, Turbine Engines, High Temperature Fasteners, Gas Turbines

- Length

- Custom Cut, up to 6 meters

- Type

- Round Bar

- Tolerance

- +/- 0.01mm

- Technique

- Hot Rolled, Cold Drawn

- Specific Use

- High Strength and Oxidation Resistance at Elevated Temperatures

- Finish

- Bright, Black, Polished

- Grade

- A286

- Material

- A286 (Iron-Nickel-Chromium Alloy)

- Processing

- Annealed, Solution Treated

- Diameter

- 6 mm to 250 mm

- Density

- 7.93 g/cm

- Manufacturing Method

- Forged or Rolled

- Corrosion Resistance

- Excellent in Oxidizing Environments

- Elongation

- Minimum 15%

- Operating Temperature

- Up to 700C

- Packaging

- Wooden cases, bundles, or as required

- Yield Strength

- Minimum 415 MPa

- Hardness

- HRB 95-107

- Surface Condition

- Smooth, free from scale and cracks

- Heat Treatment

- Can be aged and solution treated

- Tensile Strength

- Minimum 895 MPa

About A286 Round Bar

What Are Specification A286 Round Bar?

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

|---|---|

| Round bar size | Diameter: 3-~800mm |

| Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Billet Size | 1/2 to 495mm Diameter |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Dimensions | Diameter / Height: |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Technique | Stainless Steel Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, Rod |

| Processing | Bar cutting to 650mm |

| Form | Rod, Round, Channel Bar, T-Bar, Flat Bar, Precision Ground Bar, Blocks, Square, Rings, Round Rod, Triangle, Hollow, Rectangle, Threaded, Hex (A/F), Profiles, Half Round Bar, Ingot, Billet, I/H Bar, Forging etc. |

Equivalent material Of A286 Round Bar?

| UNS: | S66286 |

|---|---|

International Specifications: | W. NR. 1.4980 |

Chemical Composition Of A286 Round Bar?

| Grade | Cr | Ni | Mo | Co | Va | Al | Ti | B | C | Fe | Mn | Si | P | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Alloy A286 | 13.5-16.0 | 24.0-27.0 | 1.0-1.5 | 1.0 max | 0.1-0.5 | 0.35 max | 1.9-2.35 | 0.003-0.01 | 0.08 max | Bal | 2.0 | 1.0 | 0.025 | 0.025 |

Mechanical Properties Of A286 Round Bar?

| Temperature, F | 70* | 70 | 400 | 800 | 1000 | 1200 | 1400 |

|---|---|---|---|---|---|---|---|

| Ultimate Tensile Strength, ksi | 95* | 145 | 143 | 138 | 131 | 103 | 64 |

| 0.2% Yield Strength, ksi | 50* | 95 | 93 | 93 | 87 | 88 | 62 |

| Elongation, % | 40* | 24 | 21 | 18 | 18 | 13 | 18 |

Superior Strength and Thermal Stability

A286 round bars deliver an excellent blend of high tensile and yield strength with good ductility, maintaining their mechanical integrity even at temperatures approaching 700C. This makes them especially suitable for demanding components in gas turbines and the aerospace sector.

Exceptional Corrosion and Oxidation Resistance

Engineered with a chromium-nickel-iron matrix, A286 exhibits outstanding resistance to oxidation and corrosive environments, particularly under oxidizing conditions. This resilience greatly enhances component longevity and reliability in harsh operating conditions.

Precision Manufacturing and Versatility

Produced using hot-rolled or cold-drawn techniques, A286 round bars offer precise tolerances (+/- 0.01mm) and a range of finishes, including bright, black, and polished. Custom sizing ensures suitability for diverse industrial applications, with processing options such as annealing and solution treatment.

FAQs of A286 Round Bar:

Q: How is the A286 round bar manufactured and processed for optimal performance?

A: A286 round bars are manufactured using forged or rolled methods, followed by precise processes like annealing, solution treatment, and aging. These treatments enhance their strength and ensure a smooth, scale-free surface, matching strict mechanical and tolerance requirements.Q: What are the main applications of the A286 round bar?

A: A286 round bars are widely used in aerospace components, turbine engines, high-temperature fasteners, and gas turbines, owing to their ability to retain high strength and resist oxidation at elevated temperatures.Q: When should A286 round bars be chosen over other alloys?

A: Select A286 round bars when applications demand a combination of high strength, excellent oxidation resistance, and stable performance at temperatures up to 700C, particularly in critical engineering environments.Q: Where are A286 round bars typically sourced and supplied from?

A: A286 round bars are produced and exported internationally, with numerous manufacturers, suppliers, and exporters based in India, offering various packaging options such as wooden cases or bundles to ensure safe delivery.Q: What benefits does A286 offer compared to standard stainless steels?

A: A286 provides significantly better mechanical strength and oxidation resistance at high temperatures compared to most standard stainless steels, along with good ductility and excellent long-term reliability in corrosive, oxidizing atmospheres.Q: How can A286 round bars be customized for specific project requirements?

A: A286 round bars can be custom cut to lengths up to 6 meters, supplied in diameters ranging from 6 mm to 250 mm, and finished according to project needs, with precise tolerances and a choice of surface treatments to suit diverse industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Other Round Bars Category

Nimonic 105 Round Bar

Length : 100 mm to 6000 mm

Application : Aerospace, Gas Turbines, Power Generation, Heat Treatment, HighTemperature Environments

Standard : ASTM, AMS 5822, BS HR 504, DIN 17742

Tolerance : H9, H11, or as specified

Type : Round Bar

Technique : Hot Rolled, Forged

Nimonic 90 Round Bar

Length : 100 mm to 6000 mm

Application : Aerospace, Gas Turbine Components, Oil & Gas, Power Generation

Standard : ASTM, ASME, AMS 5829

Tolerance : H9, H11, H13, as per requirement

Type : Round Bar

Technique : Hot Rolled / Cold Drawn

Waspaloy Round Bar

Length : 36 Meter

Application : Aerospace, Gas Turbine Components, High Temperature Applications

Standard : ASTM, DIN, JIS, EN standards

Tolerance : H9, H11, or as required

Type : Round Bar

Technique : Hot Rolled

Vascomax 300 Round Bar

Length : 16 Meter

Application : Construction, Engineering, Automobile Industries

Standard : ASTM A579 / A646

Tolerance : H9, H11

Type : Round Bar

Technique : Hot Rolled

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese