AL-6XN Round Bar

AL-6XN Round Bar Specification

- Application

- Chemical processing, Seawater and brine applications, Pulp and paper industry, Food processing equipment

- Material

- AL-6XN (UNS N08367) Super Austenitic Stainless Steel

- Specific Use

- Heat exchangers, Pressure vessels, Piping, Marine hardware

- Type

- Round Bar

- Diameter

- 6 mm to 300 mm

- Technique

- Cold Drawn / Hot Rolled

- Length

- 100 mm to 3000 mm (custom lengths available)

- Grade

- AL-6XN

- Standard

- ASTM B691, ASME SB-691, ASTM B805, ASME SB-805

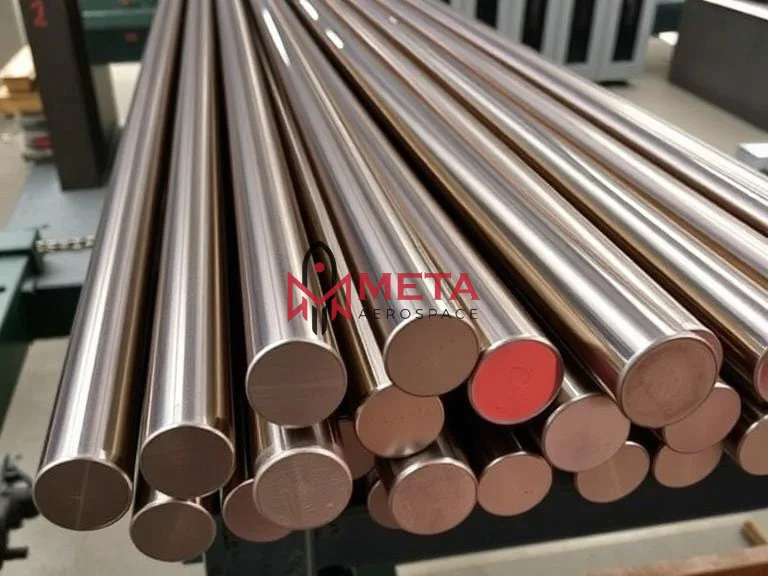

- Finish

- Bright / Polished / Black

- Processing

- Forged / Peeled / Turned / Annealed

- Tolerance

- h8, h9, h10 or as specified

- Density

- 8.06 g/cm

- Elongation

- 30%

- Surface Condition

- Smooth, Free from surface defects

- Corrosion Resistance

- Excellent resistance to chloride pitting and crevice corrosion

- Tensile Strength

- 100 ksi (690 MPa)

- Hardness

- Rockwell B90 max

- Form

- Straight / Cut-to-length

- Melting Range

- 1350 1390C

- Yield Strength (0.2% offset)

- 48 ksi (331 MPa)

About AL-6XN Round Bar

What Are Specification AL-6XN Round Bar?

| Specifications | ASTM B691 / ASME SB691 |

|---|---|

| Standard | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Range | 3.17 MM TO 350 MM DIA |

| Diameter | 25mm to 152mm |

| Length | 1 to 6 Meters, Custom Cut Lengths |

| Finish | Bright, Polish & Black |

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wiremesh, Billet, Ingot, Forging Etc. |

| Condition | Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished |

Equivalent material Of AL-6XN Round Bar?

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| AL6XN | 1.4529 | N08367 |

Chemical Composition Of AL-6XN Round Bar?

| Grade | C | Mn | Si | S | N | Cr | Ni |

|---|---|---|---|---|---|---|---|

| AL6XN | 0.03 max | 2.00 max | 1.00 max | 0.03 max | 0.18-0.25 | 20.00- 22.00 | 23.50- 25.50 |

Mechanical Properties Of AL-6XN Round Bar?

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| AL6XN | 8.1 g/cm3 | Psi 110000, MPa 760 | Psi 55100, MPa 380 | 45 % |

Exceptional Corrosion Resistance

AL-6XN Round Bar excels in environments exposed to aggressive chemicals and chloride solutions. Its composition ensures excellent pitting and crevice corrosion resistance, making it suitable for applications like seawater, brine systems, and chemical processing plants where standard stainless steels may fail.

Wide Array of Industrial Applications

This super austenitic stainless steel bar is used extensively in heat exchangers, pressure vessels, piping, marine hardware, and food processing equipment. Industries demanding reliability and durability under harsh operating conditions specifically choose AL-6XN for its mechanical properties and longevity.

Custom Sizes and Processing Options

Manufactured in diameters ranging from 6 mm to 300 mm and custom-cut lengths up to 3000 mm, AL-6XN round bars can be tailored to exact specifications. Options such as annealed, forged, turned, peeled, and bright-polished finishes are available to suit diverse engineering requirements.

FAQs of AL-6XN Round Bar:

Q: How does AL-6XN Round Bar benefit applications exposed to chloride environments?

A: The AL-6XN Round Bar offers excellent resistance to chloride-induced pitting and crevice corrosion due to its unique chemical composition. This makes it extraordinarily suitable for applications like seawater and brine handling systems, providing increased service life and reducing the risk of premature component failure.Q: What is the typical manufacturing process for AL-6XN Round Bar?

A: AL-6XN round bars are produced using cold drawn or hot rolled techniques, followed by annealing, forging, or turning to achieve the desired size and mechanical properties. Surface finishes such as bright, polished, or black can be applied, and the bars are ensured to be free from surface defects for optimal performance.Q: When should AL-6XN Round Bar be used over standard stainless steel?

A: AL-6XN is recommended over standard stainless steels when applications demand superior corrosion resistance, particularly in environments containing high chlorides, such as in chemical processing or marine settings. Its enhanced mechanical and corrosion-resistant properties contribute to longer equipment lifespan and reduced maintenance.Q: Where can AL-6XN Round Bars be applied effectively?

A: These bars are extensively used in industries like chemical processing, seawater desalination, pulp and paper, and food processing. Typical components include heat exchangers, pressure vessels, piping, and marine hardware, where durability under corrosive conditions is paramount.Q: What are the available sizes and tolerance options for AL-6XN Round Bar?

A: AL-6XN round bars are available in diameters ranging from 6 mm to 300 mm and in lengths from 100 mm to 3000 mm, with the option for custom lengths. Tolerances such as h8, h9, h10, or specific customer requirements can be accommodated to ensure precise fit and function in various applications.Q: How does the smooth surface finish of AL-6XN Round Bar enhance its performance?

A: A smooth, defect-free surface not only improves the aesthetic quality but also minimizes sites for corrosion initiation, thereby extending service life in harsh environments. High-quality finishes such as polished or bright further contribute to maintenance efficiency and product reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Other Round Bars Category

Vascomax 350 Round Bar

Technique : Hot Rolled

Tolerance : +/ 0.05 mm

Length : 16 Meter

Grade : 350

Application : Construction, Engineering, Aerospace, Automotive

Material : Vascomax 350

Nimonic 80S Round Bar

Technique : Hot Rolled / Forged

Tolerance : H9, H11, H13

Length : As per requirement / Customized

Grade : Nimonic 80A, Nimonic 80S

Application : Engineering, Construction and Manufacturing

Material : Nimonic 80S

Nimonic 75 Round Bar

Technique : Hot Rolled or Cold Drawn

Tolerance : H9, H11, H13, or as per specification

Length : 1 Meter, 2 Meter, 3 Meter, or as required

Grade : Nimonic 75 (UNS N06075)

Application : Construction, industrial, aerospace, gas turbines, heat treatment equipment

Material : Nimonic 75

Nimonic 105 Round Bar

Technique : Hot Rolled, Forged

Tolerance : H9, H11, or as specified

Length : 100 mm to 6000 mm

Grade : Nimonic 105

Application : Aerospace, Gas Turbines, Power Generation, Heat Treatment, HighTemperature Environments

Material : Nimonic 105

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese